Hose Clamp

Select vehicle to guarantee fit

- Department

- Prices

- $9.04 MSRP:

$12.75You Save: $3.71 (30%)Product Specifications- Other Names: Clamp, Lower Hose Clamp, Upper Hose Clamp

- Item Dimensions: 2.4 x 1.6 x 0.6 inches

- Item Weight: 1.00 Pounds

- Fitment Type: Direct Replacement

- Replaces: 19512-PY3-003, 19511-P30-004, 19511-P30-003, 19511-PR3-003, 19511-PT0-004, 19511-PY3-003, 19511-PK1-003

- Part Description: Clip, Hose (36.5MM) (Chuo Spring)

- $9.08 MSRP:

$12.75You Save: $3.67 (29%)Product Specifications- Other Names: Clamp, Lower Hose Clamp, Upper Hose Clamp

- Item Dimensions: 2.4 x 1.6 x 0.6 inches

- Item Weight: 1.00 Pounds

- Fitment Type: Direct Replacement

- Replaces: 19512-PY3-003, 19511-P30-004, 19511-P30-003, 19511-PR3-003, 19511-PT0-004, 19511-PY3-003, 19511-PK1-003

- Part Description: Clip, Hose (36.5MM) (Chuo Spring)

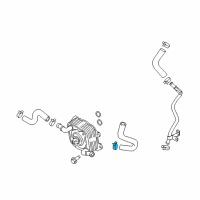

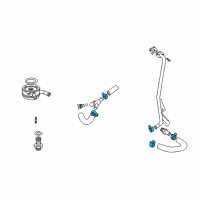

OEM (Genuine) Clip, Oil Pipe

PartNumber: 90635-RV0-003$1.59 MSRP:$2.23You Save: $0.64 (29%)Product Specifications- Item Dimensions: 1.3 x 1.0 x 0.5 inches

- Item Weight: 0.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 90635-PT0-801, 90635-PT0-802

- Part Description: Clip, Oil Pipe

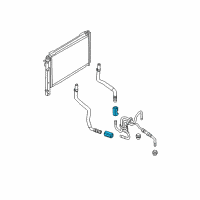

OEM (Genuine) Outlet Hose Clamp

PartNumber: 96135-51300$3.35 MSRP:$4.81You Save: $1.46 (31%)Product Specifications- Other Names: Clip Brake MC reservoir tube NO.2; bypass hose clamps/clips 1,2,3,7,8; reserve tank outlet clip

- Item Weight: 0.50 Pounds

- Fitment Type: Direct Replacement

- Replaces: 90467-13047, 90467-13039, 96135-41300, 90467-13056, 90467-13050, 90467-13001, 90080-46071

- Part Description: Outlet Hose Clamp

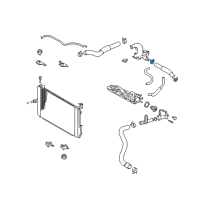

OEM (Genuine) Inlet Hose Clamp

PartNumber: 90467-37005$5.54 MSRP:$7.96You Save: $2.42 (31%)Product Specifications- Other Names: Lower Hose Clamp; Hose Clamp for Radiator Outlet NO.1 & Inlet.

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 90467-37006, 90467-37004, 90467-37002

- Part Description: Inlet Hose Clamp

- $8.64 MSRP:

$12.18You Save: $3.54 (30%)Product Specifications- Item Dimensions: 1.9 x 1.4 x 0.6 inches

- Item Weight: 0.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 19511-P08-004, 19511-PH4-003, 19511-P08-003, 91405-PP2-E01

- Part Description: Clip, Water Hose (Chuo Spring)

- $2.68 MSRP:

$3.77You Save: $1.09 (29%)Product Specifications- Item Dimensions: 2.3 x 1.8 x 0.8 inches

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Part Description: Clip, Water Hose (Topy Fasteners)

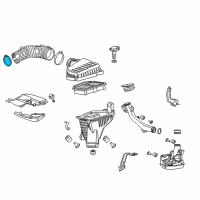

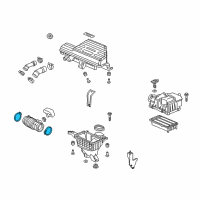

- $14.21 MSRP:

$20.05You Save: $5.84 (30%)Product Specifications- Other Names: Clamp

- Item Dimensions: 3.8 x 3.3 x 0.5 inches

- Item Weight: 0.50 Pounds

- Fitment Type: Direct Replacement

- Replaces: 17315-PH3-003

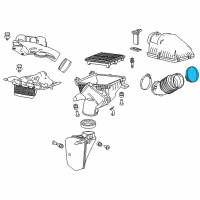

- Part Description: Clamp, Air Flow Tube (74)

OEM (Genuine) Clamp

PartNumber: 96136-52101$5.08 MSRP:$7.30You Save: $2.22 (31%)Product Specifications- Item Weight: 0.70 Pounds

- Fitment Type: Direct Replacement

- Part Description: Clamp

OEM (Genuine) Clamp

PartNumber: 16439-7S01E$3.39 MSRP:$4.62You Save: $1.23 (27%)Product Specifications- Item Dimensions: 1.1 x 1.0 x 0.5 inches

- Item Weight: 0.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 16439-7S01C, 16439-7S010, 16439-7S01A, 16439-7S01D, 16439-7S01B

- Part Description: Clamp

OEM (Genuine) Inlet Tube Clip

PartNumber: 9L8Z-7Z465-A$6.81 MSRP:$9.77You Save: $2.96 (31%)Product Specifications- Item Weight: 0.40 Pounds

- Fitment Type: Direct Replacement

- Part Description: Inlet Tube Clip

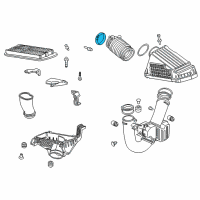

OEM (Genuine) Clamp, Air Flow (80)

PartNumber: 17315-R40-A11$20.97 MSRP:$29.63You Save: $8.66 (30%)Product Specifications- Item Dimensions: 4.1 x 4.2 x 0.5 inches

- Item Weight: 0.50 Pounds

- Fitment Type: Direct Replacement

- Part Description: Clamp, Air Flow (80)

OEM (Genuine) Clamp-Hose

PartNumber: 01558-00731$7.50 MSRP:$10.23You Save: $2.73 (27%)Product Specifications- Other Names: Lower Hose Clamp, Upper Hose Clamp

- Item Dimensions: 2.1 x 2.1 x 0.5 inches

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 01558-00311, 01558-00261, 01558-00711, 01558-00491, 01558-00551, 01558-00351, 21514-4E100

- Part Description: Clamp-Hose

OEM (Genuine) Vent Tube Clamp

PartNumber: 90080-46349$5.66 MSRP:$8.14You Save: $2.48 (31%)Product Specifications- Item Weight: 0.50 Pounds

- Fitment Type: Direct Replacement

- Replaces: 90467-19015, 96134-41900

- Part Description: Vent Tube Clamp

OEM (Genuine) Clamp, Air Flow (70)

PartNumber: 17315-R1A-A01$18.17 MSRP:$25.65You Save: $7.48 (30%)Product Specifications- Item Dimensions: 3.6 x 3.2 x 0.5 inches

- Item Weight: 0.50 Pounds

- Fitment Type: Direct Replacement

- Part Description: Clamp, Air Flow (70)

OEM (Genuine) Clamp, Air Flow (90)

PartNumber: 17316-RCA-A01$11.39 MSRP:$16.07You Save: $4.68 (30%)Product Specifications- Other Names: Air Flow Tube Clamp

- Item Dimensions: 3.8 x 3.5 x 0.5 inches

- Item Weight: 0.50 Pounds

- Fitment Type: Direct Replacement

- Part Description: Clamp, Air Flow (90)

OEM (Genuine) By-Pass Hose Clamp

PartNumber: 90467-28007$4.96 MSRP:$7.14You Save: $2.18 (31%)Product Specifications- Other Names: Clamp or Clip for Air Hose NO.1 & NO.2; Clip for Water By-Pass Hose NO.1; Standard Parts.

- Item Weight: 0.50 Pounds

- Fitment Type: Direct Replacement

- Replaces: 90467-28008

- Part Description: By-Pass Hose Clamp

OEM (Genuine) Clamp-Hose

PartNumber: 16439-56S0A$8.35 MSRP:$11.40You Save: $3.05 (27%)Product Specifications- Other Names: Overflow Hose Clamp, Water Hose Clamp

- Item Dimensions: 0.8 x 0.7 x 0.5 inches

- Item Weight: 0.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 01558-0006U, 16439-56S00

- Part Description: Clamp-Hose

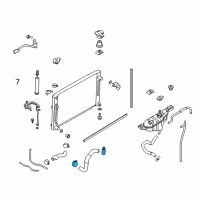

OEM (Genuine) Rear Hose Clamp

PartNumber: 11516234$5.42 MSRP:$8.17You Save: $2.75 (34%)Product Specifications- Item Dimensions: 2.7 x 2.4 x 0.7 inches

- Item Weight: 0.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 10108248, 11517144, 15024902, 21999690

- Part Description: Rear Hose Clamp

OEM (Genuine) Clip

PartNumber: 90467-37005$6.23 MSRP:$7.96You Save: $1.73 (22%)Product Specifications- Other Names: Lower Hose Clamp; Hose Clamp for Radiator Outlet NO.1 & Inlet.

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 90467-37006, 90467-37004, 90467-37002

- Part Description: Clip

OEM (Genuine) Clip, Hose

PartNumber: 90466-41008$7.91 MSRP:$10.13You Save: $2.22 (22%)Product Specifications- Other Names: Lower Hose Clamp; Hose Clamp for Radiator Outlet NO.1; Radiator Hose Clip NO.1 & NO.2.

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 90467-41007, 90467-41002, 90467-42001, 90467-41006

- Part Description: Clip, Hose

OEM (Genuine) By-Pass Hose Clamp

PartNumber: 96136-42501$5.66 MSRP:$8.14You Save: $2.48 (31%)Product Specifications- Other Names: By-Pass Hose Clamp; For Intercooler Cooling Water Hoses No.2-5; For Water By-Pass Hose & Pipe.

- Item Weight: 1.50 Pounds

- Fitment Type: Direct Replacement

- Replaces: 90466-A0023

- Part Description: By-Pass Hose Clamp

OEM (Genuine) Rear Hose Clamp

PartNumber: 96136-44301$10.28 MSRP:$14.78You Save: $4.50 (31%)Product Specifications- Other Names: Lower Hose Clamp; Hose clips for Intake Air Connector Pipe, Radiator Outlet, and Inlet.

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 90466-A0020

- Part Description: Rear Hose Clamp

OEM (Genuine) Lower Hose Clamp

PartNumber: 90466-35001$9.12 MSRP:$13.12You Save: $4.00 (31%)Product Specifications- Other Names: Upper Hose Clamp; Hose Clamp for Radiator Outlet NO.1 & Inlet; Radiator Hose Clips NO.1 & NO.2; Hose Clamp NO.3.

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Part Description: Lower Hose Clamp

OEM (Genuine) Clamp, Air Flow (75)

PartNumber: 17315-5A2-A01$19.68 MSRP:$27.78You Save: $8.10 (30%)Product Specifications- Other Names: Air Tube Clamp

- Item Dimensions: 4.1 x 3.6 x 0.5 inches

- Item Weight: 0.50 Pounds

- Fitment Type: Direct Replacement

- Part Description: Clamp, Air Flow (75)

OEM (Genuine) Clamp, Air Flow (95)

PartNumber: 17316-R70-A03$18.32 MSRP:$25.87You Save: $7.55 (30%)Product Specifications- Other Names: Air Flow Tube Clamp, Air Tube Clamp

- Item Dimensions: 4.6 x 4.3 x 0.5 inches

- Item Weight: 0.50 Pounds

- Fitment Type: Direct Replacement

- Part Description: Clamp, Air Flow (95)

OEM (Genuine) Clip

PartNumber: 01558-00521$7.50 MSRP:$10.23You Save: $2.73 (27%)Product Specifications- Item Dimensions: 1.6 x 1.3 x 0.5 inches

- Item Weight: 0.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 01558-00331, 92527-JD01A

- Part Description: Clip

OEM (Genuine) Lower Hose Clamp

PartNumber: 90467-33005$5.66 MSRP:$8.14You Save: $2.48 (31%)Product Specifications- Item Weight: 0.50 Pounds

- Part Description: Lower Hose Clamp

OEM (Genuine) Clamp-Hose

PartNumber: 01558-00731$7.53 MSRP:$10.23You Save: $2.70 (27%)Product Specifications- Other Names: Lower Hose Clamp, Upper Hose Clamp

- Item Dimensions: 2.1 x 2.1 x 0.5 inches

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 01558-00311, 01558-00261, 01558-00711, 01558-00491, 01558-00551, 01558-00351, 21514-4E100

- Part Description: Clamp-Hose

OEM (Genuine) Upper Hose Clamp

PartNumber: 90466-41006$12.24 MSRP:$17.61You Save: $5.37 (31%)Product Specifications- Other Names: Upper Hose Clamp; For Radiator Outlet NO.1 & Inlet; Standard Parts.

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Part Description: Upper Hose Clamp

About Hose Clamp

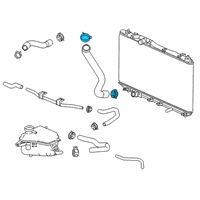

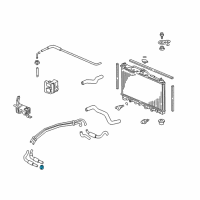

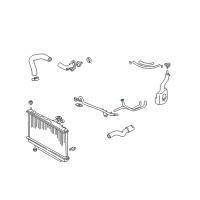

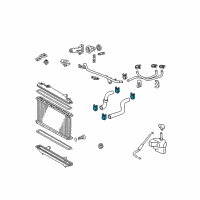

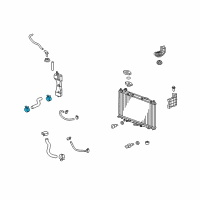

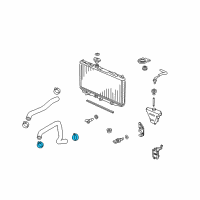

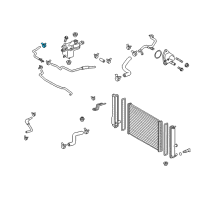

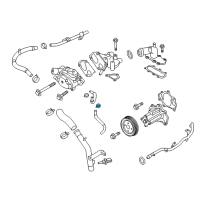

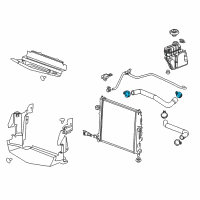

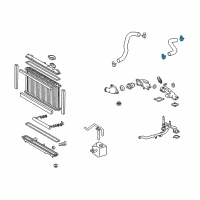

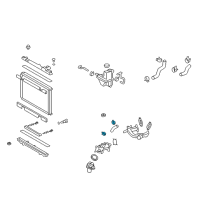

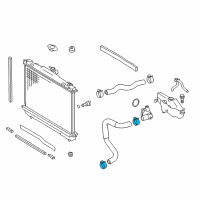

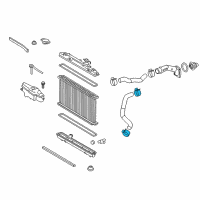

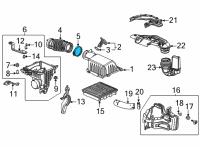

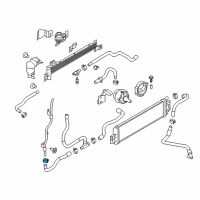

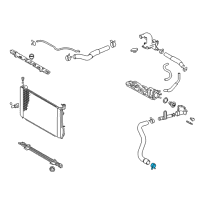

Hoses that are filled with fluid are usually connected to machinery with a clamp. Clamps usually hold down the coolant hoses that connect to the radiator as well as the motor. There are three common types of hose clamps.

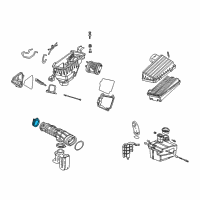

Types of hose clampsThe screw clamp is also known as a worm gear clamp. It features a built-in screw and is composed of metal like stainless steel. The screw clamp has the screw attached to the thread pattern that is utilized to tighten or loosen them.

The constant tension is another type of clamp that is made to apply pressure to the hose consistently. This type of clamp does not have a screw, but it does have a spring and ring-like shape to it. It requires a different kind of procedure to install the constant-tension clamp like compressing the ends simultaneously.

Another type is the wire clamp, but it is not utilized as much as the other two. The design consists of a single wire that is pressed and manipulated into a "U" shape. The opening side of the U-shaped design has a captive nut and screw, and with the screw unfastened you can locate the wire clamp over the hose and add the screw.

Common problems with a faulty hose clampEach hose clamp has a unique feature that retains the hoses and brake lines from leaking. A faulty hose clamp can lead to leaking which can be caused by under-tightening or over-tightening.