Crankshaft Position Sensor

Select vehicle to guarantee fit

- Department

- Brands

- Prices

$73.92Product Specifications

$73.92Product Specifications- Connector Gender: Female

- Connector Quantity: 1

- Connector Shape: Oval

- Connector/Terminal Configuration: Blade

- Material: Plastic

- Mount Hole Quantity: 2

- Mounting Bracket Included: Yes

- Sensor Body Diameter: 1.32"

- Terminal Gender: Male

- Terminal Quantity: 6

- UPC: 889245168368

- Wire Quantity: 0

- Wiring Harness Included: No

- Part Description: OE Solutions Crankshaft Position Sensor

Denso® Crankshaft Position Sensor

PartNumber: 196-2013$160.29Product Specifications- Connector Gender: Female

- Connector Quantity: 1

- Connector Shape: Oval

- Mounting Bracket Included: NO

- Mounting Hole Quantity: 1

- Terminal Gender: Male

- Terminal Quantity: 3

- Terminal Type: Blade

- UPC: 042511219298

- Wiring Harness Included: NO

- Part Description: Crankshaft Position Sensor

Delphi® Crankshaft Position Sensor

PartNumber: SS11404$128.91Product Specifications- Color: Black

- Connector Gender: Male

- Connector Quantity: 1

- Connector Shape: Oval

- Package Contents: Engine Crankshaft Position Sensor, Instruction Sheet

- Terminal Gender: Male

- Terminal Quantity: 6

- Terminal Type: Pin

- UPC: 689604303733

- Part Description: Crankshaft Position Sensor

Spectra Premium® Crankshaft Position Sensor

PartNumber: MZ54$191.82Product Specifications- Connector Gender: Male

- Connector Shape: Rectangular

- Terminal Count: 4

- Terminal Shape: Blade

- UPC: 874183004984

- Part Description: Crankshaft Position Sensor

$66.24Product Specifications

$66.24Product Specifications- Color: Black

- Connector Gender: Female

- Connector Quantity: 1

- Connector Shape: Oblong

- Mounting Hole Quantity: 1

- Terminal Gender: Male

- Terminal Quantity: 3

- Terminal Type: Spade

- UPC: 724620130205

- Part Description: Crankshaft Position Sensor

- $163.37 MSRP:

$230.77You Save: $67.40 (30%)Product Specifications- Other Names: Crankshaft Sensor

- Item Dimensions: 3.4 x 2.9 x 2.7 inches

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Part Description: Sensor Assembly, Crank

Hella® Sensor Crankshaft

PartNumber: 009163681$113.37Product Specifications- Cable Length [mm]: 400

- Internet Product Code (IPC): D59892D5BC4

- Item has MSDS: No

- MFG Brand Name: Hella Inc.

- MFG Model # (Series): 009163681

- Number of pins: 3

- Resistor [Ohm]: 580

- Sensor Type: Inductive Sensor

- Supplier Company Name: Hella Inc.

- Voltage [V]: 12

- Part Description: Sensor Crankshaft

facet® Crankshaft Position Sensor

PartNumber: 9.0068$49.57Product Specifications- Part Description: Crankshaft Position Sensor

MTC® Crankshaft Position Sensor

PartNumber: 2037$9.58Product Specifications- UPC: 849290051114

- Part Description: Crankshaft Position Sensor

$42.06Product Specifications

$42.06Product Specifications- Connector Gender: Female

- Connector Quantity: 1

- Connector Shape: Oval

- Connector/Terminal Configuration: Blade

- Material: Plastic

- Mount Hole Quantity: 1

- Sensor Body Diameter: 0.73"

- Terminal Gender: Male

- Terminal Quantity: 3

- UPC: 889245165985

- Wire Quantity: 0

- Part Description: OE Solutions Crankshaft Position Sensor

Denso® Engine Crankshaft Position Sensor

PartNumber: 196-4004$155.95Product Specifications- Connector Gender: Female

- Connector Quantity: 1

- Connector Shape: Oval

- Mounting Bracket Included: NO

- Mounting Hole Quantity: 1

- Terminal Gender: Male

- Terminal Quantity: 3

- Terminal Type: Pin

- UPC: 042511219304

- Wiring Harness Included: NO

- Part Description: Engine Crankshaft Position Sensor

- $143.41 MSRP:

$202.57You Save: $59.16 (30%)Product Specifications- Other Names: Crankshaft Position Sensor, Crankshaft Sensor

- Item Dimensions: 2.6 x 1.6 x 0.9 inches

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 37500-PNC-006

- Part Description: Sensor Assembly, Crank

Delphi® Crankshaft Position Sensor

PartNumber: SS11019$117.21Product Specifications- Package Contents: Engine Crankshaft Position Sensor, Instruction Sheet

- UPC: 689604281420

- Part Description: Crankshaft Position Sensor

$72.80Product Specifications

$72.80Product Specifications- Connector Gender: Male

- Connector Shape: Oval

- Terminal Count: 2

- Terminal Shape: Blade

- UPC: 627785018046

- Part Description: Crankshaft Position Sensor

VEMO® Crankshaft Position Sensor

PartNumber: V30-72-0108$276.23Product Specifications- Cable Length [mm]: 980

- Connector Shape: Round

- Fitting Depth [mm]: 39

- Number of Connectors: 2

- Number of Poles: 2

- Packaging Depth [cm]: 9

- Packaging height [cm]: 9,2

- Packaging width [cm]: 5,15

- Rated Voltage [V]: 12

- Resistance [Ohm]: 850

- Sensor Type: Inductive Sensor

- Supplementary Article/Info 2: with cable

- Weight [kg]: 0,094

- Part Description: Crankshaft Position Sensor

facet® Crankshaft Position Sensor

PartNumber: 9.0212$57.45Product Specifications- Part Description: Crankshaft Position Sensor

$119.32Product Specifications

$119.32Product Specifications- Connector Gender: Female

- Connector Quantity: 1

- Connector Shape: Oval

- Connector/Terminal Configuration: Blade

- Material: Plastic

- Mount Hole Quantity: 1

- Sensor Body Diameter: 0.81"

- Terminal Gender: Female

- Terminal Quantity: 3

- UPC: 889245168665

- Wire Quantity: 3

- Wiring Harness Length: 13.1"

- Part Description: OE Solutions Crankshaft Position Sensor

- $122.82 MSRP:

$173.48You Save: $50.66 (30%)Product Specifications- Item Dimensions: 5.7 x 5.3 x 1.0 inches

- Item Weight: 0.60 Pounds

- Replaces: 23731-7Y000, 23731-AL616, 23731-7Y001, 23731-AL61A, 23731-AL615, 23731-AL610

- Part Description: Engine Camshaft Position Sensor

Denso® Crankshaft Position Sensor

PartNumber: 196-2103$125.25Product Specifications- Connector Gender: Female

- Connector Quantity: 1

- Connector Shape: Oval

- Mounting Bracket Included: NO

- Mounting Hole Quantity: 1

- Terminal Gender: Male

- Terminal Quantity: 4

- Terminal Type: Blade

- UPC: 042511211919

- Wire Quantity: 4

- Wiring Harness Included: YES

- Wiring Harness Length: 22.50

- Part Description: Crankshaft Position Sensor

Delphi® Crankshaft Position Sensor

PartNumber: SS10229$58.92Product Specifications- Package Contents: Engine Crankshaft Position Sensor, Instruction Sheet

- UPC: 689604106983

- Part Description: Crankshaft Position Sensor

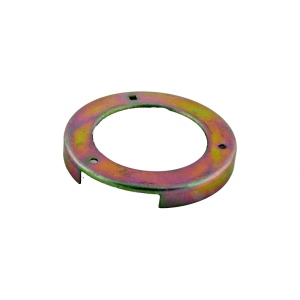

$312.99Product Specifications

$312.99Product Specifications- Color: Silver

- Connector Gender: Male

- Connector Quantity: 1

- Connector Shape: Round

- Mounting Hole Quantity: 3

- Terminal Gender: Female

- Terminal Quantity: 4

- Terminal Type: Spade

- UPC: 724620137914

- Part Description: Crankshaft Position Sensor

Hella® Crankshaft Position Sensor

PartNumber: 009163361$111.74Product Specifications- Internet Product Code (IPC): 8930A7BF391

- Item has MSDS: No

- Length [mm]: 48,7

- MFG Brand Name: Hella Inc.

- MFG Model # (Series): 009163361

- Number of pins: 3

- Sensor Type: Hall Sensor

- Supplementary Article/Info 2: without cable

- Supplier Company Name: Hella Inc.

- UPC: 760687145462

- Part Description: Crankshaft Position Sensor

facet® Crankshaft Position Sensor

PartNumber: 9.0437$51.26Product Specifications- Part Description: Crankshaft Position Sensor

- $235.41 MSRP:

$332.52You Save: $97.11 (30%)Product Specifications- Other Names: Crankshaft Sensor

- Item Dimensions: 2.9 x 2.3 x 2.1 inches

- Item Weight: 0.50 Pounds

- Fitment Type: Direct Replacement

- Replaces: 37500-PLC-005

- Part Description: Sensor Assembly, Crank

$80.49Product Specifications

$80.49Product Specifications- Connector Gender: Female

- Connector Quantity: 2

- Connector Shape: Square; Circular

- Connector/Terminal Configuration: Pin; Blade

- Material: Plastic

- Mount Hole Quantity: 2

- Sensor Body Diameter: 1.34"

- Terminal Gender: Female

- Terminal Quantity: 4; 1

- UPC: 889245168689

- Wire Quantity: 4

- Wiring Harness Length: 25"

- Part Description: OE Solutions Plastic Crankshaft Position Sensor

Denso® Crankshaft Position Sensor

PartNumber: 196-1110$108.89Product Specifications- Connector Gender: Female

- Connector Quantity: 1

- Connector Shape: Oval

- Mounting Bracket Included: NO

- Mounting Hole Quantity: 1

- Terminal Gender: Male

- Terminal Quantity: 2

- Terminal Type: Blade

- UPC: 042511211810

- Wire Quantity: 3

- Wiring Harness Included: YES

- Wiring Harness Length: 09.00

- Part Description: Crankshaft Position Sensor

VEMO® Crankshaft Position Sensor

PartNumber: V20-72-0074$29.22Product Specifications- Colour: Black

- Fitting Depth [mm]: 28

- for OE number: 13 62 7 525 015

- Number of Connectors: 3

- Number of Poles: 3

- Packaging Depth [cm]: 5

- Packaging height [cm]: 4,1

- Packaging width [cm]: 2,3

- Rated Voltage [V]: 12

- Supplementary Article/Info 2: without cable

- Weight [kg]: 0,027

- Part Description: Crankshaft Position Sensor

$47.82Product Specifications

$47.82Product Specifications- Part Description: Standard Optional Crankshaft Position Sensor

$58.21Product Specifications

$58.21Product Specifications- Connector Gender: Female

- Connector Quantity: 1

- Connector Shape: Rectangular

- Connector/Terminal Configuration: Blade

- Material: Plastic

- Mount Hole Quantity: 1

- Mounting Bracket Included: Yes

- Sensor Body Diameter: 0.70"

- Terminal Gender: Male

- Terminal Quantity: 3

- UPC: 889245169068

- Wire Quantity: 3

- Wiring Harness Included: Yes

- Wiring Harness Length: 20.5"

- Part Description: OE Solutions Crankshaft Position Sensor

- $129.47 MSRP:

$182.89You Save: $53.42 (30%)Product Specifications- Other Names: Crankshaft Position Sensor, Crankshaft Sensor

- Item Dimensions: 3.4 x 3.0 x 2.8 inches

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 37500-PNA-003

- Part Description: Sensor Assembly, Crank

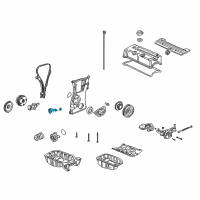

About Crankshaft Position Sensor

The crankshaft position sensor is vital to the vehicle, as it keeps track of the position or rotation speed of the crankshaft. It is important that the information is sent to the powertrain control module since the data helps the timing for the ignition and fuel injection. There are different types of sensor that the crankshaft position sensor uses.

Various sensorsThe different types of sensor have a specific use for the engine, like the inductive, Hall Effect, magneto resistive, and optical sensor. An inductive sensor is a more simplistic and are purely there to help out. While the Hall Effect and magneto resistive have more of a benefit and are active since they can detect static.

Crankshaft position sensor roleThe job of the crankshaft is to know the rotational speed also known as the RPM of the crank. The timing is also controlled by the engine control units which is transferred by the sensors, and for a diesel the sensor is in command of the fuel injector.

Common issues with the crankshaft position sensorThe crankshaft position sensor is known for helping to keep the timing of your vehicle efficiently, but a bad crankshaft can lead to engine misfires, noises, and poor engine performance.