< Back ×

Chrysler 200 Oil Pressure Sensor

Select vehicle to guarantee fit

Make

Model

Year

< Back to View All

Engine Sensors, Switches & Relays

- Department

- Brands

- Prices

$31.44Product Specifications

$31.44Product Specifications- Body Material: Metal

- Color/Finish: Black

- Connector Color: Black

- Connector Gender: Male

- Connector Quantity: 1

- Connector Shape: Rectangular

- OE Part Number: 5149062AA, 56044777AA, 5149062AB, 68060337AA

- Terminal Gender: Male

- Terminal Quantity: 3

- Terminal Type: Blade

- UPC: 037495920193

- Wire Harness Included: No

- Part Description: Chrysler 200 OE Solutions Oil Pressure Sensor

- $60.05 MSRP:

$86.70You Save: $26.65 (31%)Product Specifications- Item Dimensions: 7.5 x 6.7 x 5.0 inches

- Item Weight: 1.10 Pounds

- Replaces: 56044777AA, 5149062AA, 68060337AA

- Part Description: Chrysler 200 Switch-Oil Pressure

About Chrysler 200 Oil Pressure Sensor

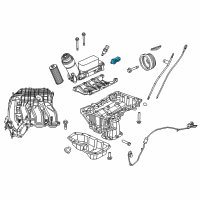

The first-generation Chrysler 200 is a refreshed version of the Chrysler Sebring featuring many changes in powertrain and appearance. The Chrysler 200 has received much acclaim from drivers and retailers for its excellent riding performance and reliable safety system. Classic parts like the oil pressure sensor parts contribute to the success of the Chrysler 200. Most Chrysler 200 cars today have an oil pressure sensor that has a direct link with the oil pressure.

Whereas, the worn oil pressure sensor needs to be repaired or replaced for better Chrysler 200 performance. An oil pressure sensor gives you an accurate reading of the oil pressure in the engine block while the model is being driven or even idling. The gauge should read 3/4 of the way full or all the way, any lower and the model should not be driven under low oil pressure to avoid any damage to the internals of the engine. Low oil pressure on the gauge does not necessarily mean it has low oil pressure it is best to not drive the vehicle until the sensor is tested or replaced. Here are the steps to replacing the Chrysler 200 oil pressure sensor. Firstly locate the oil pressure sensor on your Chrysler 200 vehicle. Next use the correct oil pressure sensor socket to remove the sensor parts. Then add thread sealant to the threads of the new unit and torque the sensor to the proper torque rating before installing the new unit. Our large assortment covers the majority of classic vehicles. Buyers can get great products and services online 24 hours a day and 7 days a week.