< Back ×

My Vehicle Change Vehicle

2010 GMC Yukon

< Back to View All

Fuses & Fuse Box

- Department

- Prices

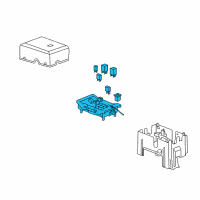

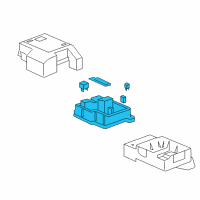

OEM (Genuine) 2010 GMC Yukon Block Asm-Engine Wiring Harness Junction

PartNumber: 22798217 Product Specifications

Product Specifications- Notes: Engine Compartment; Engine Compartment, Main Block

- Other Names: Junction Block

- Item Dimensions: 9.7 x 5.7 x 15.8 inches

- Item Weight: 3.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25941368

- Part Description: 2010 GMC Yukon Block Asm-Engine Wiring Harness Junction

Vehicle Fitment- 2010 GMC Yukon | Denali, Denali Hybrid, Hybrid, SLE, SLT | 8 Cyl 5.3 L FLEX, 8 Cyl 6.0 L ELECTRIC/FLEX, 8 Cyl 6.2 L FLEX

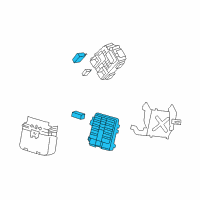

$338.67 MSRP:$537.71You Save: $199.04 (38%)OEM (Genuine) 2010 GMC Yukon Block Asm-Body Wiring Harness Junction

PartNumber: 20813086 Product Specifications

Product Specifications- Notes: Instrument Panel, Lower

- Other Names: Junction Block

- Item Dimensions: 8.3 x 8.1 x 6.2 inches

- Item Weight: 3.00 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15780696

- Part Description: 2010 GMC Yukon Block Asm-Body Wiring Harness Junction

Vehicle Fitment- 2010 GMC Yukon | Denali, SLE, SLT | 8 Cyl 4.8 L GAS, 8 Cyl 5.3 L FLEX, 8 Cyl 5.3 L GAS, 8 Cyl 6.2 L FLEX

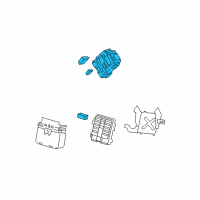

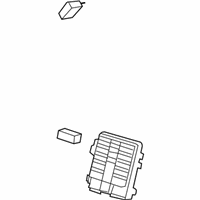

$174.35 MSRP:$276.81You Save: $102.46 (38%)OEM (Genuine) 2010 GMC Yukon Block Asm-Fuse

PartNumber: 20828606 Product Specifications

Product Specifications- Notes: Instrument Panel, Upper

- Other Names: Fuse Box, Junction Block

- Item Dimensions: 7.8 x 6.3 x 6.1 inches

- Item Weight: 0.80 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25815391

- Part Description: 2010 GMC Yukon Block Asm-Fuse

Vehicle Fitment- 2010 GMC Yukon | Denali, Denali Hybrid, Hybrid, SLE, SLT | 8 Cyl 4.8 L GAS, 8 Cyl 5.3 L FLEX, 8 Cyl 5.3 L GAS, 8 Cyl 6.0 L ELECTRIC/FLEX, 8 Cyl 6.0 L ELECTRIC/GAS, 8 Cyl 6.2 L FLEX, 8 Cyl 6.2 L GAS

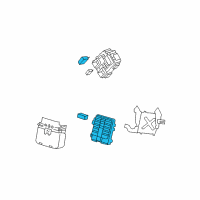

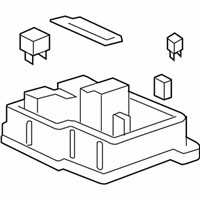

$98.25 MSRP:$156.00You Save: $57.75 (38%)OEM (Genuine) 2010 GMC Yukon Block Asm-Body Wiring Harness Junction

PartNumber: 20813087 Product Specifications

Product Specifications- Notes: Instrument Panel, Lower

- Other Names: Junction Block

- Item Dimensions: 7.9 x 6.5 x 6.3 inches

- Item Weight: 1.00 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15939775

- Part Description: 2010 GMC Yukon Block Asm-Body Wiring Harness Junction

Vehicle Fitment- 2010 GMC Yukon | Denali Hybrid, Hybrid | 8 Cyl 6.0 L ELECTRIC/FLEX, 8 Cyl 6.0 L ELECTRIC/GAS

OEM (Genuine) 2010 GMC Yukon Block Asm-Accessory Wiring Junction

PartNumber: 25949656 Product Specifications

Product Specifications- Notes: Engine Compartment, Accessory Block

- Other Names: Junction Block

- Item Dimensions: 14.2 x 13.1 x 4.9 inches

- Item Weight: 2.00 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25867571

- Part Description: 2010 GMC Yukon Block Asm-Accessory Wiring Junction

Vehicle Fitment- 2010 GMC Yukon | Denali Hybrid, Hybrid | 8 Cyl 6.0 L ELECTRIC/FLEX, 8 Cyl 6.0 L ELECTRIC/GAS

FAQ for Fuse Box Repair

Q: What is the preliminary procedure for the 200 Amp Mega Fuse and Auxiliary Electrical Center 12VDC Junction Block removal?

A:

You can disconnect the battery negative cable, and disconnect the battery positive cable.

By Bob

GM Specialist

01/11/2022Q: How to remove M6 Weld Stud?

A:

You can select a location adjacent the damaged or missing M6 ground stud having 20 mm (0.79 in) clearance behind the panel surface and 20 mm (0.79 in) clearance surrounding the M6 rivet stud flange, remove any grease from the repair site and allow to dry, drill a 10 mm (0.40 in) diameter hole through the panel, remove paint and primer from the area surrounding the rivet stud flange until bare metal is visible, select a replacement conductive M6 rivet stud, install the replacement conductive M6 rivet stud, ensure the new rivet stud is securely fastened, with no detectable movement, wrap the threads of the rivet stud with painters tape or equivalent, refinish the repair area using an anti-corrosion primer, allow the refinished repair area to cure sufficiently before removing the protective material applied to the rivet stud threads, remove the painters tape or equivalent from the rivet stud threads, thoroughly clean the rivet stud threads to remove any adhesive and allow to dry, remove any corrosion from the electrical ground wire terminal, apply Dielectric Lubricant GM P/N 12377900 (Canadian P/N 10953529) to the new conductive M6 rivet stud threads, install the ground terminal to the new rivet stud, select a new, conductive M6 nut, install the M6 nut, check for proper system operation.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the 200 Amp Mega Fuse nut?

A:

The recommended torque is 7 Nm (62 lb in).

By Bob

GM Specialist

01/11/2022Q: How to install the 175 Amp Mega Fuse?

A:

You can install the fuse cover, the starter solenoid cable nut, the starter solenoid cable terminal, the generator battery jumper cable to fuse nut, the generator battery jumper cable terminal, the generator battery jumper cable terminal, and the fuse.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the 200 Amp Mega Fuse junction block nut?

A:

The recommended torque is 7 Nm (62 lb in).

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the generator battery jumper cable to fuse nut?

A:

The recommended torque is 15 Nm (11 lb-ft).

By Bob

GM Specialist

01/11/2022Q: How many mega-fuse holder nuts does 175 Amp Mega Fuse have?

A:

It has a total of 1 mega-fuse holder nut.

By Bob

GM Specialist

01/11/2022Q: What is the preliminary procedure for the 175 Amp Mega Fuse removal?

A:

You can remove the.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the starter solenoid cable nut?

A:

The recommended torque is 15 Nm (11 lb-ft).

By Bob

GM Specialist

01/11/2022Q: How to remove the 175 Amp Mega Fuse?

A:

You can disconnect the negative battery cable, remove the fuse cover, the starter solenoid cable nut, the starter solenoid cable terminal, the generator battery jumper cable to fuse nut, the generator battery jumper cable terminal, the generator battery jumper cable terminal, the fuse.

By Bob

GM Specialist

01/11/2022See more FAQs (12)