< Back ×

My Vehicle Change Vehicle

2010 GMC Yukon

< Back to View All

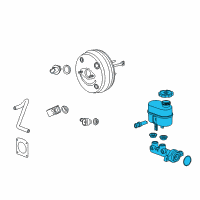

Brake Boosters & Brake Master Cylinders

- Department

- Series

- Brands

- Prices

OEM (Genuine) 2010 GMC Yukon Cylinder Asm-Brake Master

PartNumber: 20845345 Product Specifications

Product Specifications- Other Names: Master Cylinder

- Item Dimensions: 9.8 x 7.5 x 9.5 inches

- Item Weight: 4.30 Pounds

- Replaced by: 19432757

- Part Description: 2010 GMC Yukon Cylinder Asm-Brake Master

Vehicle Fitment- 2010 GMC Yukon | Denali, SLE, SLT | 8 Cyl 4.8 L GAS, 8 Cyl 5.3 L FLEX, 8 Cyl 5.3 L GAS, 8 Cyl 6.2 L FLEX

$139.86 MSRP:$277.52You Save: $137.66 (50%)

Centric® Premium Brake Master Cylinder for 2010 GMC Yukon

PartNumber: 130.66066Product Specifications- UPC: 805890527862

- Part Description: 2010 GMC Yukon Premium Brake Master Cylinder

Vehicle Fitment- 2010 GMC Yukon | All Trims | All Engines

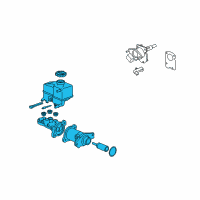

$79.59OEM (Genuine) 2010 GMC Yukon CYLINDER ASM, BRK MAS

PartNumber: 19420798 Product Specifications

Product Specifications- Notes: Tahoe, Yukon, Escalade; W/O Active Brake Control

- Other Names: Master Cylinder

- Fitment Type: Direct Replacement

- Replaced by: 19432757

- Part Description: 2010 GMC Yukon CYLINDER ASM, BRK MAS

Vehicle Fitment- 2010 GMC Yukon | Denali, SLE, SLT | 8 Cyl 4.8 L GAS, 8 Cyl 5.3 L FLEX, 8 Cyl 5.3 L GAS, 8 Cyl 6.2 L FLEX

$139.86 MSRP:$277.52You Save: $137.66 (50%)OEM (Genuine) 2010 GMC Yukon Master Cylinder

PartNumber: 19417185 Product Specifications

Product Specifications- Other Names: Master Cylinder

- Replaced by: 19432757

- Part Description: 2010 GMC Yukon Master Cylinder

Vehicle Fitment- 2010 GMC Yukon | Denali, SLE, SLT | 8 Cyl 4.8 L GAS, 8 Cyl 5.3 L FLEX, 8 Cyl 5.3 L GAS, 8 Cyl 6.2 L FLEX

$147.08 MSRP:$277.52You Save: $130.44 (48%)

Cardone Reman® Remanufactured Master Cylinder for 2010 GMC Yukon

PartNumber: 10-4198Product Specifications- Notes: Supplied w/o Reservoir

- Bore Diameter: 1.250" (31.75 mm)

- Casting Material: Aluminum

- Master Cylinder Color: Gray

- Master Cylinder Material: Aluminum

- Master Cylinder Primary Port Size: M14 x 1.5

- Master Cylinder Secondary Port Size: M14 x 1.5

- Mounting Hardware Included: No

- Mounting Hole Count: 2

- Port Quantity: 2

- Reservoir: Without

- Part Description: 2010 GMC Yukon Remanufactured Master Cylinder

Vehicle Fitment- 2010 GMC Yukon | All Trims | All Engines

Centric® Premium™ Brake Master Cylinder for 2010 GMC Yukon

PartNumber: 130.66065Product Specifications- UPC: 805890497820

- Part Description: 2010 GMC Yukon Premium™ Brake Master Cylinder

Vehicle Fitment- 2010 GMC Yukon | Hybrid | All Engines

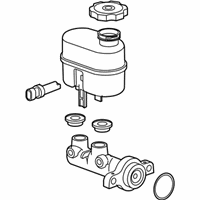

OEM (Genuine) 2010 GMC Yukon Cylinder Asm-Brake Master

PartNumber: 22936000 Product Specifications

Product Specifications- Notes: Tahoe, Yukon, Escalade; All;Tahoe, Yukon, Escalade; W/Active Brake Control

- Other Names: Master Cylinder

- Item Dimensions: 14.6 x 14.6 x 11.1 inches

- Item Weight: 5.20 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15775174, 20759706

- Part Description: 2010 GMC Yukon Cylinder Asm-Brake Master

Vehicle Fitment- 2010 GMC Yukon | Denali, Denali Hybrid, Hybrid, SLE, SLT | 8 Cyl 4.8 L GAS, 8 Cyl 5.3 L FLEX, 8 Cyl 5.3 L GAS, 8 Cyl 6.0 L ELECTRIC/FLEX, 8 Cyl 6.0 L ELECTRIC/GAS, 8 Cyl 6.2 L FLEX, 8 Cyl 6.2 L GAS

FAQ for Brake Master Cylinder Repair

Q: What is the recommended torque for the brake master cylinder primary brake pipe fitting?

A:

The recommended torque is 30 Nm (22 lb-ft).

By Bob

GM Specialist

01/11/2022Q: How to bleed Master Cylinder Bench?

A:

You can secure the mounting flange of the brake master cylinder in a bench vise so that the rear of the primary piston is accessible, remove the master cylinder reservoir cap and diaphragm, install suitable fittings to the master cylinder ports that match the type of flare seat required and also provide for hose attachment, install transparent hoses to the fittings installed to the master cylinder ports, then route the hoses into the master cylinder reservoir, fill the master cylinder reservoir to at least the half-way point with GM approved brake fluid from a clean, sealed brake fluid container, ensure that the ends of the transparent hoses running into the master cylinder reservoir are fully submerged in the brake fluid, depress and release the primary piston as far as it will travel, a depth of about 25 mm (1 in), several times, observe the flow of fluid coming from the ports. As air is bled from the primary and secondary pistons, the effort required to depress the primary piston will increase and the amount of travel will decrease, continue to depress and release the primary piston until fluid flows freely from the ports with no evidence of air bubbles, remove the transparent hoses from the master cylinder reservoir, install the master cylinder reservoir cap and diaphragm, remove the fittings with the transparent hoses from the master cylinder ports. Wrap the master cylinder with a clean shop cloth to prevent brake fluid spills, and remove the master cylinder from the vise.

By Bob

GM Specialist

01/11/2022Q: How many brake pipe fittings does Master Cylinder have?

A:

It has a total of 2 brake pipe fittings.

By Bob

GM Specialist

01/11/2022Q: How to remove the Brake Master Cylinder Adapter?

A:

You can place the transmission in the PARK or NEUTRAL position, apply the park brake, turn the ignition to OFF, without pausing at ACCESSORY, and without applying the brake pedal, remove the ignition key, wait for approximately 1 to 3 minutes until the brake modulator and HPA pressure relief is complete, remove the master cylinder nuts, release and carefully position aside the master cylinder, support the master cylinder with heavy mechanics wire or equivalent, disconnect the brake master cylinder (BMC) primary piston position sensor electrical connector, remove the brake pushrod retainer bolt, remove the brake pushrod retainer, slide the stop lamp switch off of the brake pedal pushrod pin while simultaneously disconnecting the brake pushrod, remove the 4 brake pedal bracket nuts, the brake master cylinder adapter.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the brake master cylinder left supply brake pipe fitting?

A:

The recommended torque is 30 Nm (22 lb-ft).

By Bob

GM Specialist

01/11/2022Q: How to install the Master Cylinder Reservoir?

A:

You can install the 3 master cylinder reservoir seals, the master cylinder reservoir to the master cylinder, the brake master cylinder reservoir pins, connect the brake master cylinder reservoir return hose quick connect, connect the brake master cylinder reservoir supply hose quick connect, connect the brake fluid level sensor electrical connector, fill the brake master cylinder reservoir.

By Bob

GM Specialist

01/11/2022Q: How to remove the Brake Master Cylinder Reservoir Hose?

A:

You can turn the ignition to OFF, without pausing at ACCESSORY, and remove the ignition key, wait approximately 1 to 3 minutes until the brake modulator and HPA pressure relief is complete, remove the brake fluid from the brake master cylinder reservoir until the level is below the reservoir supply hose fitting and discard into an approved container, disconnect the brake fluid level sensor electrical connector, d isconnect the brake master cylinder reservoir return hose quick connect, disconnect the brake master cylinder reservoir supply hose quick connect, remove the antilock brake system (ABS) module splash shield retainers, the ABS module splash shield bolts, the ABS module splash shield, disconnect the BPMV supply hose quick connect, cap the BPMV inlet port and plug the supply hose to prevent brake fluid loss and contamination, disconnect the BPMV return hose quick connect, cap the BPMV outlet port and plug the return hose to prevent brake fluid loss and contamination, release the supply and return hoses from the retainers and remove the hoses from the vehicle.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the ABS module splash shield bolts?

A:

The recommended torque is 20 Nm (15 lb-ft).

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the brake master cylinder nuts?

A:

The recommended torque is 36 Nm (27 lb-ft).

By Bob

GM Specialist

01/11/2022Q: How many master cylinder reservoir seals does Master Cylinder Reservoir have?

A:

It has a total of 2 master cylinder reservoir seals.

By Bob

GM Specialist

01/11/2022See more FAQs (15)