< Back ×

2010 GMC Sierra 3500 HD Brake Disc

My Vehicle Change Vehicle

2010 GMC Sierra 3500 HD

< Back to View All

Brake Pads, Discs & Calipers

- Department

- Brands

- Prices

Power Stop® PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair for 2010 GMC Sierra 3500 HD

PartNumber: AR8644XPR$289.49Product Specifications- Notes: SRW

- Bolt Circle: 165.1mm (6.5")

- Driving Style: Performance / Racing

- Hub Hole Diameter: 122.68mm (4.83")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.51mm (0.65")

- Minimum Thickness: 27mm (1.06")

- Nominal Thickness: 29.21mm (1.15")

- Quantity: 2 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (13")

- Rotor Finish: Zinc Coated

- Rotor Height: 91.44mm (3.6")

- Rotor Material: Cast Iron

- Rotor Style: Drilled & Slotted

- Rotor Type: Vented

- Part Description: 2010 GMC Sierra 3500 HD PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$60.13Product Specifications

$60.13Product Specifications- Notes: SRW

- UPC: 805890036302

- Part Description: 2010 GMC Sierra 3500 HD Premium Vented Rear Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$66.64Product Specifications

$66.64Product Specifications- Notes: DRW

- Bolt Circle: 165mm (6.50")

- Center Hole Diameter: 122.8mm (4.83")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.5mm (0.65")

- Minimum Thickness: 28.5mm (1.12")

- Nominal Thickness: 30mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 325mm (12.8")

- Rotor Height: 132.3mm (5.21")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632122350

- Part Description: 2010 GMC Sierra 3500 HD Vented Rear Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

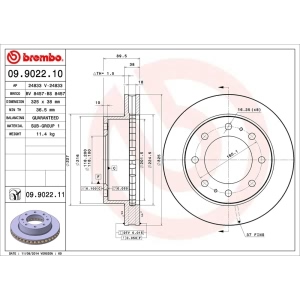

$96.72Product Specifications

$96.72Product Specifications- Notes: GVW 12,000 Lbs.

- Center Diameter: 118

- Coated: UV Coated

- Diameter (mm): 325

- Height: 89.4

- Material: Grey Cast Iron

- Minimum Thickness (mm): 36.5

- Nominal Thickness (mm): 38

- Number of Holes: 8

- Quantity: 8

- Solid Or Vented Type Rotor: vented

- Torque Spec(NM): 150

- Part Description: 2010 GMC Sierra 3500 HD UV Coated Series Vented Front Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | SLE | All Engines

- 2010 GMC Sierra 3500 HD | SLT | All Engines

- 2010 GMC Sierra 3500 HD | WT | All Engines

Power Stop® PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair for 2010 GMC Sierra 3500 HD

PartNumber: AR8655XPR$329.90Product Specifications- Bolt Circle: 165.1mm (6.5")

- Driving Style: Performance / Racing

- Hub Hole Diameter: 118.2mm (4.65")

- Lug Holes Quantity: 8

- Lug Holes Size: 416.56mm (16.4")

- Minimum Thickness: 36.5mm (1.44")

- Nominal Thickness: 38.1mm (1.5")

- Quantity: 2 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 325mm (12.8")

- Rotor Finish: Zinc Coated

- Rotor Height: 89mm (3.5")

- Rotor Material: Cast Iron

- Rotor Style: Drilled & Slotted

- Rotor Type: Vented

- Part Description: 2010 GMC Sierra 3500 HD PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

- $198.29 MSRP:

$374.16You Save: $175.87 (48%)Product Specifications- Notes: 2WD, 3/4 & 1 Ton, W/O Dual Rear Wheels; 4WD, 3/4 & 1 Ton, W/O Dual Rear Wheels

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 13.9 x 14.0 x 3.8 inches

- Item Weight: 29.10 Pounds

- Fitment Type: Direct Replacement

- Replaces: 18060654

- Part Description: 2010 GMC Sierra 3500 HD Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | SLE, SLT, WT | 8 Cyl 6.0 L FLEX, 8 Cyl 6.0 L GAS, 8 Cyl 6.6 L DIESEL

$61.93Product Specifications

$61.93Product Specifications- UPC: 805890208440

- Part Description: 2010 GMC Sierra 3500 HD Premium Vented Front Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$63.77Product Specifications

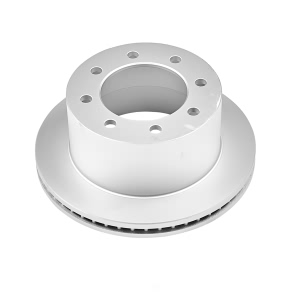

$63.77Product Specifications- Notes: DRW

- Bolt Circle: 165.1mm (6.5")

- Center Hole Diameter: 118.2mm (4.65")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.4mm (0.65")

- Minimum Thickness: 36.5mm (1.44")

- Nominal Thickness: 38.1mm (1.5")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 325.1mm (12.8")

- Rotor Height: 89.2mm (3.51")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632127096

- Part Description: 2010 GMC Sierra 3500 HD Vented Front Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$121.57Product Specifications

$121.57Product Specifications- Notes: DRW

- Bolt Circle: 165.1mm (6.5")

- Hub Hole Diameter: 122.68mm (4.83")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.38mm (0.65")

- Minimum Thickness: 28.5mm (1.12")

- Nominal Thickness: 30mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 324mm (12.76")

- Rotor Height: 132.06mm (5.2")

- Rotor Style: Plain

- Part Description: 2010 GMC Sierra 3500 HD PowerStop Evolution Coated Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$67.17Product Specifications

$67.17Product Specifications- Notes: DRW

- UPC: 805890075172

- Part Description: 2010 GMC Sierra 3500 HD Premium™ Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$54.60Product Specifications

$54.60Product Specifications- Notes: SRW

- Bolt Circle: 165.1mm (6.5")

- Center Hole Diameter: 122.9mm (4.84")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.5mm (0.65")

- Minimum Thickness: 27mm (1.06")

- Nominal Thickness: 29mm (1.14")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Height: 92.5mm (3.64")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632117165

- Part Description: 2010 GMC Sierra 3500 HD Vented Rear Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

- $175.27 MSRP:

$325.78You Save: $150.51 (47%)Product Specifications- Notes: Disc Brakes, 3/4 & 1 Ton, W/O Dual Rr Wheels

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 17.0 x 16.8 x 6.3 inches

- Item Weight: 30.20 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2010 GMC Sierra 3500 HD Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | SLE, SLT, WT | 8 Cyl 6.0 L FLEX, 8 Cyl 6.0 L GAS, 8 Cyl 6.6 L DIESEL

$88.99Product Specifications

$88.99Product Specifications- Notes: GVW 9,900 Lbs.

- Coated: UV Coated

- Diameter (mm): 330

- Height: 90

- Material: Grey Cast Iron

- Minimum Thickness (mm): 27

- Nominal Thickness (mm): 29

- Number of Holes: 8

- Quantity: 8

- Solid Or Vented Type Rotor: vented

- Part Description: 2010 GMC Sierra 3500 HD UV Coated Series Vented Rear Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | SLE | All Engines

- 2010 GMC Sierra 3500 HD | SLT | All Engines

- 2010 GMC Sierra 3500 HD | WT | All Engines

$104.04Product Specifications

$104.04Product Specifications- Bolt Circle: 165.1mm (6.5")

- Hub Hole Diameter: 118.2mm (4.65")

- Lug Holes Quantity: 8

- Lug Holes Size: 416.56mm (16.4")

- Minimum Thickness: 36.5mm (1.44")

- Nominal Thickness: 38.1mm (1.5")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 325mm (12.8")

- Rotor Height: 89mm (3.5")

- Rotor Style: Plain

- Part Description: 2010 GMC Sierra 3500 HD PowerStop Evolution Coated Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$74.06Product Specifications

$74.06Product Specifications- Notes: DRW

- UPC: 889590393514

- Part Description: 2010 GMC Sierra 3500 HD GCX Plain 1-Piece Rear Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$47.08Product Specifications

$47.08Product Specifications- Notes: SRW

- Bolt Circle: 165.1mm (6.5")

- Center Hole Diameter: 118.2mm (4.65")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.6mm (0.65")

- Minimum Thickness: 36.5mm (1.44")

- Nominal Thickness: 38mm (1.50")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 324.8mm (12.79")

- Rotor Height: 89.2mm (3.51")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632126280

- Part Description: 2010 GMC Sierra 3500 HD Vented Front Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$91.30Product Specifications

$91.30Product Specifications- Notes: SRW

- Bolt Circle: 165.1mm (6.5")

- Hub Hole Diameter: 122.68mm (4.83")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.51mm (0.65")

- Minimum Thickness: 27mm (1.06")

- Nominal Thickness: 29.21mm (1.15")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Height: 91.44mm (3.6")

- Rotor Style: Plain

- Part Description: 2010 GMC Sierra 3500 HD PowerStop Evolution Coated Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

- $155.17 MSRP:

$292.81You Save: $137.64 (48%)Product Specifications- Notes: Disc Brakes, 3/4 & 1 Ton, W/Dual Rr Wheels; Silverado, Sierra; 3500 Series

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 16.1 x 16.6 x 7.8 inches

- Item Weight: 31.90 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2010 GMC Sierra 3500 HD Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | SLE, SLT, WT | 8 Cyl 6.0 L FLEX, 8 Cyl 6.0 L GAS, 8 Cyl 6.6 L DIESEL

$69.51Product Specifications

$69.51Product Specifications- UPC: 889590393521

- Part Description: 2010 GMC Sierra 3500 HD GCX Plain 1-Piece Front Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$122.19Product Specifications

$122.19Product Specifications- Notes: SRW

- UPC: 805890133308

- Part Description: 2010 GMC Sierra 3500 HD Premium Vented Rear Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$83.41Product Specifications

$83.41Product Specifications- Notes: DRW

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212083442

- Part Description: 2010 GMC Sierra 3500 HD QuietCast™ Premium Front Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$100.12Product Specifications

$100.12Product Specifications- Notes: SRW

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212086092

- Part Description: 2010 GMC Sierra 3500 HD QuietCast™ Premium Front Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

$80.22Product Specifications

$80.22Product Specifications- Notes: SRW

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212082742

- Part Description: 2010 GMC Sierra 3500 HD QuietCast™ Premium Vented Rear Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

- $151.77 MSRP:

$286.38You Save: $134.61 (48%)Product Specifications- Notes: Silverado, Sierra; 3500 Series; 2WD, 3/4 & 1 Ton, W/Dual Rear Wheels; 4WD, 3/4 & 1 Ton, W/Dual Rear Wheels

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 14.0 x 13.5 x 4.2 inches

- Item Weight: 29.90 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15733625

- Part Description: 2010 GMC Sierra 3500 HD Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | SLE, SLT, WT | 8 Cyl 6.0 L FLEX, 8 Cyl 6.0 L GAS, 8 Cyl 6.6 L DIESEL

Product Specifications

Product Specifications- Notes: DRW

- UPC: 805890527442

- Part Description: 2010 GMC Sierra 3500 HD Premium™ High Carbon Alloy Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

Product Specifications

Product Specifications- Notes: GVW 9,900 Lbs.

- Coated: UV Coated

- Diameter (mm): 325

- Height: 89

- Material: Grey Cast Iron

- Minimum Thickness (mm): 36.5

- Nominal Thickness (mm): 38

- Number of Holes: 8

- Quantity: 8

- Solid Or Vented Type Rotor: vented

- Part Description: 2010 GMC Sierra 3500 HD UV Coated Series Front Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | SLE | All Engines

- 2010 GMC Sierra 3500 HD | SLT | All Engines

- 2010 GMC Sierra 3500 HD | WT | All Engines

Product Specifications

Product Specifications- UPC: 889590253078

- Part Description: 2010 GMC Sierra 3500 HD GCX Rotor With Partial Coating

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

Product Specifications

Product Specifications- Notes: SRW

- UPC: 889590252996

- Part Description: 2010 GMC Sierra 3500 HD GCX Plain 1-Piece Rear Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

Product Specifications

Product Specifications- Notes: DRW

- UPC: 889590253016

- Part Description: 2010 GMC Sierra 3500 HD GCX Rotor With Partial Coating

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

Product Specifications

Product Specifications- Notes: 8 Stud Wheel;26 Ribs;with 12,000lb Gross Vehicle Weight (GVW);with 325mm Diameter Rotor;with Black E-Coat on non-braking surface to prevent rust and corrosion

- Bolt Circle: 165.1mm (6.5")

- Lug Holes Quantity: 8

- Minimum Thickness: 36.5mm (1.44")

- Nominal Thickness: 38.1mm (1.5")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 324.87mm (12.79")

- Rotor Finish: With E-Shield™ Coating

- Rotor Height: 89.408mm (3.52")

- Rotor Material: Cast Iron

- Rotor Style: Plain

- UPC: 008536941705

- Part Description: 2010 GMC Sierra 3500 HD Vented Front Brake Rotor

Vehicle Fitment- 2010 GMC Sierra 3500 HD | All Trims | All Engines

1-30 of 33 Results

< Previous

12

Next >FAQ for Brake Disc Repair

Q: How to install the Rear Brake Rotor?

A:

You should install each of the new wheel studs into the hub and rotor assembly, the hub and rotor assembly, apply the brake pedal, release the brake pedal, fill the master cylinder reservoir, install the tire and wheel assembly and then burnish the brake pads and rotors.

By Bob

GM Specialist

01/11/2022Q: How to remove the Rear Brake Rotor?

A:

You should remove the tire and wheel assembly, remove the hub and rotor assembly, mark the relationship of the hub to the rotor, place the hub and rotor assembly on a hydraulic press, press the wheel studs out of the hub and rotor assembly and then separate the hub from the rotor.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the Brake Caliper Bracket bolts?

A:

The recommended torque is 175 N.m (129 lb-ft).

By Bob

GM Specialist

01/11/2022Q: What special tools will I be needing when I service the Brake Rotor Retainer?

A:

You will be needing a Rotor Resurfacing Kit and a Wheel Hub Resurfacing Kit.

By Bob

GM Specialist

01/11/2022Q: What special tools will I be needing when I service the Brake Rotor?

A:

You will be needing a Rotor Resurfacing Kit and a Wheel Hub Resurfacing Kit.

By Bob

GM Specialist

01/11/2022Q: How to service the Brake Caliper Bracket bolts?

A:

You should remove all traces of the adhesive patch on the brake caliper bracket bolts and threaded holes of the brake caliper bracket, clean the brake caliper bracket bolt threads and the threaded holes of the brake caliper bracket with denatured alcohol.

By Bob

GM Specialist

01/11/2022Q: How to service the Brake Rotor?

A:

You should mark the position of the brake rotor to the wheel stud, clean any rust or corrosion from the mating surface of the hub/axle flange, clean any rust or corrosion from the mating surface of the brake rotor, and then burnish the brake pads and rotors.

By Bob

GM Specialist

01/11/2022Q: How many bolts attach to the Brake Caliper Bracket?

A:

There are 2 bolts attached to the Brake Caliper Bracket.

By Bob

GM Specialist

01/11/2022Q: Which lathe is essential for performing brake work, the bench or the on-car?

A:

Dealers must have a well-maintained bench lathe and a well-maintained on-car lathe. These lathes need to be calibrated monthly. BOTH lathes are essential to providing quality brake service.

By Bob

GM Specialist

01/11/2022Q: How do on-car lathes react to Axle Float? Does the play affect the machining of the rotor, either surface finish or LRO?

A:

Because the Pro-Cut on-car lathe adjusts in a live mode while spinning the hub/rotor, the dynamics of a floating axle are effectively eliminated. Once the lathe is compensated, there is no difference in the cutting/surface finish and LRO are just the same as with a non-floating axle.

By Bob

GM Specialist

01/11/2022See more FAQs (6)