< Back ×

My Vehicle Change Vehicle

2010 Chevrolet Equinox

< Back to View All

Brake Pads, Discs & Calipers

- Department

- Brands

- Prices

OEM (Genuine) 2010 Chevrolet Equinox Rotor

PartNumber: 23118055 Product Specifications

Product Specifications- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 15.4 x 14.6 x 3.7 inches

- Item Weight: 23.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 13501320

- Part Description: 2010 Chevrolet Equinox Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | L, LS, LT, LTZ, Premier | 4 Cyl 2.4 L FLEX, 4 Cyl 2.4 L GAS, 6 Cyl 3.0 L FLEX, 6 Cyl 3.0 L GAS, 6 Cyl 3.6 L FLEX, 6 Cyl 3.6 L GAS

$94.39 MSRP:$178.11You Save: $83.72 (48%)

Centric® Premium Vented Front Brake Rotor for 2010 Chevrolet Equinox

PartNumber: 120.62120Product Specifications- UPC: 805890592150

- Part Description: 2010 Chevrolet Equinox Premium Vented Front Brake Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | All Trims | All Engines

$63.65

Power Stop® PowerStop Evolution Coated Rotor for 2010 Chevrolet Equinox

PartNumber: AR82126EVCProduct Specifications- Bolt Circle: 120mm (4.72")

- Hub Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 5

- Lug Holes Size: 411.48mm (16.2")

- Minimum Thickness: 27mm (1.06")

- Nominal Thickness: 29.9mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 321mm (12.64")

- Rotor Height: 51mm (2.01")

- Rotor Style: Plain

- Part Description: 2010 Chevrolet Equinox PowerStop Evolution Coated Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | All Trims | All Engines

$75.70

DuraGo® Vented Front Brake Rotor for 2010 Chevrolet Equinox

PartNumber: BR900748Product Specifications- Bolt Circle: 120mm (4.72")

- Center Hole Diameter: 67.5mm (2.66")

- Lug Holes Quantity: 5

- Lug Holes Size: 16.3mm (0.64")

- Minimum Thickness: 27mm (1.06")

- Nominal Thickness: 30mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 321mm (12.64")

- Rotor Height: 51mm (2.01")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632172591

- Part Description: 2010 Chevrolet Equinox Vented Front Brake Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | All Trims | All Engines

$37.59

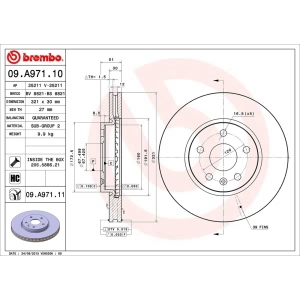

brembo® UV Coated Series Vented Front Brake Rotor for 2010 Chevrolet Equinox

PartNumber: 09.A971.11Product Specifications- Center Diameter: 67.4

- Coated: UV Coated

- Diameter (mm): 321

- Fixing Screws: included

- Height: 51

- Material: High Carbon

- Minimum Thickness (mm): 27

- Nominal Thickness (mm): 30

- Number of Holes: 5

- OE Part Number: 13501297, 13501320, 13502214, 23118055, 569064, 569422, 23118530

- Quantity: 5

- Screw Material: Included

- Solid Or Vented Type Rotor: vented

- Torque Spec(NM): 150

- Part Description: 2010 Chevrolet Equinox UV Coated Series Vented Front Brake Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | LTZ | All Engines

- 2010 Chevrolet Equinox | LS | All Engines

- 2010 Chevrolet Equinox | LT | All Engines

$78.55

Bosch® QuietCast™ Premium Rear Brake Rotor for 2010 Chevrolet Equinox

PartNumber: 25011463Product Specifications- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212086078

- Part Description: 2010 Chevrolet Equinox QuietCast™ Premium Rear Brake Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | All Trims | All Engines

$52.23OEM (Genuine) 2010 Chevrolet Equinox Rotor

PartNumber: 20792027 Product Specifications

Product Specifications- Notes: W/O AWD; W/AWD

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 4.0 x 13.3 x 12.6 inches

- Item Weight: 17.30 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2010 Chevrolet Equinox Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | L, LS, LT, LTZ, Premier | 4 Cyl 2.4 L FLEX, 4 Cyl 2.4 L GAS, 6 Cyl 3.0 L FLEX, 6 Cyl 3.0 L GAS, 6 Cyl 3.6 L FLEX, 6 Cyl 3.6 L GAS

$187.50 MSRP:$353.80You Save: $166.30 (48%)

Power Stop® PowerStop Evolution Coated Rotor for 2010 Chevrolet Equinox

PartNumber: AR82152EVCProduct Specifications- Bolt Circle: 120mm (4.72")

- Hub Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 5

- Lug Holes Size: 411.48mm (16.2")

- Minimum Thickness: 18.4mm (0.72")

- Nominal Thickness: 20mm (0.79")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Drum-in-Hat

- Rotor Diameter: 303mm (11.93")

- Rotor Height: 71.7mm (2.82")

- Rotor Style: Plain

- Part Description: 2010 Chevrolet Equinox PowerStop Evolution Coated Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | All Trims | All Engines

$53.92

DuraGo® Vented Rear Brake Rotor for 2010 Chevrolet Equinox

PartNumber: BR900824Product Specifications- Bolt Circle: 120mm (4.72")

- Center Hole Diameter: 67.5mm (2.66")

- Lug Holes Quantity: 5

- Lug Holes Size: 16mm (0.63")

- Minimum Thickness: 18.4mm (0.72")

- Nominal Thickness: 20mm (0.79")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 303mm (11.93")

- Rotor Height: 71.7mm (2.82")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632173000

- Part Description: 2010 Chevrolet Equinox Vented Rear Brake Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | All Trims | All Engines

$28.50

Bosch® QuietCast™ Premium Front Brake Rotor for 2010 Chevrolet Equinox

PartNumber: 25011437Product Specifications- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 321mm (12.64")

- Rotor Style: Plain

- UPC: 077212085743

- Part Description: 2010 Chevrolet Equinox QuietCast™ Premium Front Brake Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | All Trims | All Engines

$58.49

Centric® Premium Vented Rear Brake Rotor for 2010 Chevrolet Equinox

PartNumber: 120.66073Product Specifications- UPC: 805890619864

- Part Description: 2010 Chevrolet Equinox Premium Vented Rear Brake Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | All Trims | All Engines

$51.72

Centric® GCX Plain 1-Piece Rear Brake Rotor for 2010 Chevrolet Equinox

PartNumber: 320.66073Product Specifications- UPC: 889590253153

- Part Description: 2010 Chevrolet Equinox GCX Plain 1-Piece Rear Brake Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | All Trims | All Engines

$43.54

Centric® GCX Plain 1-Piece Front Brake Rotor for 2010 Chevrolet Equinox

PartNumber: 320.62120Product Specifications- UPC: 889590252330

- Part Description: 2010 Chevrolet Equinox GCX Plain 1-Piece Front Brake Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | All Trims | All Engines

brembo® UV Coated Series Rear Brake Rotor for 2010 Chevrolet Equinox

PartNumber: 09.A629.21Product Specifications- Coated: UV Coated

- Diameter (mm): 303

- Fixing Screws: included

- Height: 72

- Material: Grey Cast Iron

- Minimum Thickness (mm): 18.4

- Nominal Thickness (mm): 20

- Number of Holes: 5

- OE Part Number: 20792027

- Quantity: 5

- Screw Material: Included

- Solid Or Vented Type Rotor: vented

- Part Description: 2010 Chevrolet Equinox UV Coated Series Rear Brake Rotor

Vehicle Fitment- 2010 Chevrolet Equinox | LTZ | All Engines

- 2010 Chevrolet Equinox | LS | All Engines

- 2010 Chevrolet Equinox | LT | All Engines

FAQ for Brake Disc Repair

Q: What tools can be used to clean the rust from the brake rotor flange?

A:

You can use the J-41013-Rotor Resurfacing Kit.

By Bob

GM Specialist

01/11/2022Q: Which lathe is essential for performing brake work, the bench or the on-car?

A:

Dealers must have a well-maintained bench lathe and a well-maintained on-car lathe. These lathes need to be calibrated monthly. BOTH lathes are essential to providing quality brake service.

By Bob

GM Specialist

01/11/2022Q: How do you install the Front Brake Rotor?

A:

You can clean any rust or corrosion from the mating surface of the hub/axle flange, clean any rust or corrosion from the mating surface of the rotor to the hub/axle flange, install the brake rotor and the brake rotor bolt, position the brake caliper and bracket assembly to the vehicle, install the brake caliper bracket bolts, install the tire and wheel assembly and burnish the brake pads and rotors.

By Bob

GM Specialist

01/11/2022Q: How do you install the Rear Brake Rotor?

A:

You can clean any rust or corrosion from the mating surface of the hub/axle flange, clean any rust or corrosion from the mating surface of the rotor to the hub/axle flange, install the brake rotor and the brake rotor bolt, position the brake caliper and bracket assembly to the vehicle, install the brake caliper bracket bolts, adjust the park brake, install the tire and wheel assembly and burnish the brake pads and rotors.

By Bob

GM Specialist

01/11/2022Q: What is the removal procedure for the Rear Brake Rotor?

A:

The procedure is to raise the vehicle and remove the tire and wheel assembly, the brake caliper bracket bolts, the brake caliper, and bracket assembly, brake rotor bolt, the brake rotor, and the park brake shoe adjuster access plug.

By Bob

GM Specialist

01/11/2022Q: What is the removal procedure for the Front Brake Rotor?

A:

The procedure is to raise the vehicle and remove the tire and wheel assembly, the brake caliper bracket bolts, the brake caliper, and bracket assembly, the brake rotor bolt, and the brake rotor.

By Bob

GM Specialist

01/11/2022Q: What is the expected tip life for an on-car lathe?

A:

The geometry and composition of the Pro-Cut tips are designed for °single pass° cutting. When using the Pro-Cut the cutting depth should be set to take all material needed to get below rust grooves, eliminate all run-out and resurface the entire disc in a single pass. Cuts of 0.1016-0.381 mm (0.004-0.015 in) will provide the best surface finish and the optimal tip life. No °skim cut° or °finish cut° is needed. Failure to follow this procedure will shorten tip life. The Pro-cut tips will last between 7-12 cuts per corner. With three usable corners, a pair of tips is good for at least 21 cuts.

By Bob

GM Specialist

01/11/2022Q: How do you refinish the brake rotor?

A:

You can clean the wheel bearing/hub, measure the thinnest point of the brake rotor, clean the rust from the brake rotor flange, refinish the brake rotor, create a non-directional braking surface and clean the braking surfaces.

By Bob

GM Specialist

01/11/2022Q: What tools can be used to clean the wheel bearing/hub?

A:

You can use the J-42450-A-Wheel Hub Resurfacing Kit.

By Bob

GM Specialist

01/11/2022See more FAQs (4)