< Back ×

My Vehicle Change Vehicle

2010 Cadillac SRX

< Back to View All

Brake Pads, Discs & Calipers

- Department

- Brands

- Prices

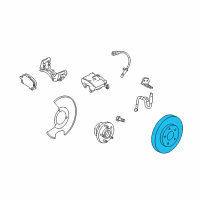

OEM (Genuine) 2010 Cadillac SRX Rotor

PartNumber: 13501318 Product Specifications

Product Specifications- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 15.4 x 14.8 x 3.7 inches

- Item Weight: 27.40 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2010 Cadillac SRX Rotor

Vehicle Fitment- 2010 Cadillac SRX | Base, Luxury, Performance, Premium | 6 Cyl 2.8 L GAS, 6 Cyl 3.0 L GAS, 6 Cyl 3.6 L FLEX, 6 Cyl 3.6 L GAS

$99.30 MSRP:$187.38You Save: $88.08 (48%)

Centric® Premium Vented Front Brake Rotor for 2010 Cadillac SRX

PartNumber: 120.62126Product Specifications- UPC: 805890619376

- Part Description: 2010 Cadillac SRX Premium Vented Front Brake Rotor

Vehicle Fitment- 2010 Cadillac SRX | All Trims | All Engines

$73.56

Power Stop® PowerStop Evolution Coated Rotor for 2010 Cadillac SRX

PartNumber: AR82145EVCProduct Specifications- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- Part Description: 2010 Cadillac SRX PowerStop Evolution Coated Rotor

Vehicle Fitment- 2010 Cadillac SRX | All Trims | All Engines

$85.70

DuraGo® Vented Front Brake Rotor for 2010 Cadillac SRX

PartNumber: BR900840Product Specifications- Bolt Circle: 120mm (4.72")

- Center Hole Diameter: 67.5mm (2.66")

- Lug Holes Quantity: 6

- Lug Holes Size: 16mm (0.63")

- Minimum Thickness: 27mm (1.06")

- Nominal Thickness: 30mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 345mm (13.58")

- Rotor Height: 51mm (2.01")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632173086

- Part Description: 2010 Cadillac SRX Vented Front Brake Rotor

Vehicle Fitment- 2010 Cadillac SRX | All Trims | All Engines

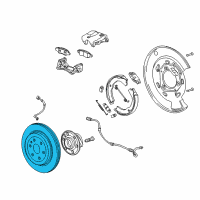

$51.48OEM (Genuine) 2010 Cadillac SRX Rotor

PartNumber: 13501317 Product Specifications

Product Specifications- Notes: W/O AWD; W/AWD

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 4.0 x 15.5 x 14.7 inches

- Item Weight: 16.30 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2010 Cadillac SRX Rotor

Vehicle Fitment- 2010 Cadillac SRX | Base, Luxury, Performance, Premium | 6 Cyl 2.8 L GAS, 6 Cyl 3.0 L GAS, 6 Cyl 3.6 L FLEX, 6 Cyl 3.6 L GAS

$83.07 MSRP:$164.83You Save: $81.76 (50%)

Centric® Premium Vented Rear Brake Rotor for 2010 Cadillac SRX

PartNumber: 120.62123Product Specifications- UPC: 805890619369

- Part Description: 2010 Cadillac SRX Premium Vented Rear Brake Rotor

Vehicle Fitment- 2010 Cadillac SRX | All Trims | All Engines

$47.03

DuraGo® Vented Rear Brake Rotor for 2010 Cadillac SRX

PartNumber: BR900842Product Specifications- Bolt Circle: 120mm (4.72")

- Center Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 6

- Lug Holes Size: 16mm (0.63")

- Minimum Thickness: 21.5mm (0.85")

- Nominal Thickness: 23mm (0.91")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 315mm (12.4")

- Rotor Height: 48mm (1.89")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632173093

- Part Description: 2010 Cadillac SRX Vented Rear Brake Rotor

Vehicle Fitment- 2010 Cadillac SRX | All Trims | All Engines

$35.87

Centric® GCX Rotor With Partial Coating for 2010 Cadillac SRX

PartNumber: 320.62123Product Specifications- UPC: 889590391893

- Part Description: 2010 Cadillac SRX GCX Rotor With Partial Coating

Vehicle Fitment- 2010 Cadillac SRX | All Trims | All Engines

Bosch® QuietCast™ Premium Front Brake Rotor for 2010 Cadillac SRX

PartNumber: 25011449Product Specifications- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085927

- Part Description: 2010 Cadillac SRX QuietCast™ Premium Front Brake Rotor

Vehicle Fitment- 2010 Cadillac SRX | All Trims | All Engines

Bosch® QuietCast™ Premium Rear Brake Rotor for 2010 Cadillac SRX

PartNumber: 25011450Product Specifications- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085934

- Part Description: 2010 Cadillac SRX QuietCast™ Premium Rear Brake Rotor

Vehicle Fitment- 2010 Cadillac SRX | All Trims | All Engines

Centric® GCX Rotor With Partial Coating for 2010 Cadillac SRX

PartNumber: 320.62126Product Specifications- UPC: 889590391923

- Part Description: 2010 Cadillac SRX GCX Rotor With Partial Coating

Vehicle Fitment- 2010 Cadillac SRX | All Trims | All Engines

FAQ for Brake Disc Repair

Q: Which lathe is essential for performing brake work, the bench or the on-car?

A:

Dealers must have a well-maintained bench lathe and a well-maintained on-car lathe. These lathes need to be calibrated monthly. BOTH lathes are essential to providing quality brake service.

By Bob

GM Specialist

01/11/2022Q: How do on-car lathes react to Axle Float? Does the play affect the machining of the rotor, either surface finish or LRO?

A:

Because the Pro-Cut on-car lathe adjusts in a live mode while spinning the hub/rotor, the dynamics of a floating axle are effectively eliminated. Once the lathe is compensated, there is no difference in the cutting/surface finish and LRO are just the same as with a non-floating axle.

By Bob

GM Specialist

01/11/2022Q: What do we need to note when we accelerate the vehicle?

A:

You should use care to avoid overheating the brakes while performing this step.

By Bob

GM Specialist

01/11/2022Q: Why does GM recommend the use of single pass (referred to as "positive rake") bench and on-car brake lathes?

A:

GM Service and GM Brake Engineering have performed competitive evaluations on a significant number of bench and on-car brake lathes. These tests measured critical performance characteristics such as flatness, surface finish, and the ability of the lathe to repeat accuracy over many uses. In each test, single-pass lathe designs outperformed the competitors. Single-pass brake lathes are more productive requiring less time to perform the same procedure.

By Bob

GM Specialist

01/11/2022Q: What special tools do we need when we replace the front brake rotor?

A:

The special tools we need are CH-41013-rotor resurfacing kit and the CH-42450-A-wheel hub resurfacing kit.

By Bob

GM Specialist

01/11/2022Q: What special tools do we need when we replace the rear brake rotor?

A:

The special tools we need are CH-41013-rotor resurfacing kit and the CH-42450-A-wheel hub resurfacing kit.

By Bob

GM Specialist

01/11/2022Q: Is it okay to leave the caliper/pads installed while cutting rotors using an on-car lathe?

A:

On-car lathes should never be used with the pads and calipers installed on the vehicle. The debris from cutting the rotors can contaminate the brake pads/calipers which can lead to other brake concerns and comebacks.

By Bob

GM Specialist

01/11/2022Q: What do we need to note when the vehicle is equipped with cross-drilled rotors?

A:

You should use a lathe with positive rake tooling. This setup requires less cutting pressure, which will result in less vibration, and a better surface finish. Also, you should use a vibration dampener when cutting and refinishing according to the following instructions.

By Bob

GM Specialist

01/11/2022Q: What information needs to be documented on the Repair Order?

A:

Any claim that is submitted using the labor operations in this bulletin, must have the Original Rotor Thickness and Refinish Rotor Thickness (if refinished) documented on the repair order. For more information, refer to the °Repair Order Required Documentation° section of this bulletin.

By Bob

GM Specialist

01/11/2022Q: How to remove the front brake rotor?

A:

First, you should raise and support the vehicle and remove the tire and wheel assembly. Then, you should remove the brake caliper bracket bolts. Without disconnecting the brake caliper hose, you should remove the brake caliper and bracket assembly and support with heavy mechanics wire or equivalent. If installing the original brake rotor, you should mark the relationship of the rotor to the wheel hub. Finally, you should remove the brake rotor bolt and the brake rotor.

By Bob

GM Specialist

01/11/2022See more FAQs (8)