< Back ×

My Vehicle Change Vehicle

2009 GMC Savana 3500

< Back to View All

Brake Pads, Discs & Calipers

- Department

- Brands

- Prices

OEM (Genuine) 2009 GMC Savana 3500 Rotor

PartNumber: 22950036 Product Specifications

Product Specifications- Notes: AWD

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 13.5 x 13.8 x 3.5 inches

- Item Weight: 27.30 Pounds

- Fitment Type: Direct Replacement

- Replaces: 88963556, 25819670

- Part Description: 2009 GMC Savana 3500 Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | Base, LS, LT | 8 Cyl 4.8 L FLEX, 8 Cyl 4.8 L GAS, 8 Cyl 6.0 L CNG, 8 Cyl 6.0 L FLEX, 8 Cyl 6.0 L GAS, 8 Cyl 6.6 L DIESEL

$131.04 MSRP:$247.27You Save: $116.23 (48%)

Centric® Premium Vented Rear Brake Rotor for 2009 GMC Savana 3500

PartNumber: 120.66071Product Specifications- Notes: DRW

- UPC: 805890520078

- Part Description: 2009 GMC Savana 3500 Premium Vented Rear Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$101.52OEM (Genuine) 2009 GMC Savana 3500 Rotor

PartNumber: 15942198 Product Specifications

Product Specifications- Notes: RWD, 1 Ton; Express, Savana; 1 Ton; Under 9600 Gvwr

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 13.9 x 14.0 x 3.8 inches

- Item Weight: 29.10 Pounds

- Fitment Type: Direct Replacement

- Replaces: 18060654

- Part Description: 2009 GMC Savana 3500 Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | Base, LS, LT, SLE | 4 Cyl 2.8 L DIESEL, 6 Cyl 4.3 L FLEX, 6 Cyl 4.3 L GAS, 8 Cyl 4.8 L FLEX, 8 Cyl 4.8 L GAS, 8 Cyl 6.0 L CNG, 8 Cyl 6.0 L FLEX, 8 Cyl 6.0 L GAS, 8 Cyl 6.6 L DIESEL, 8 Cyl 6.6 L GAS

$163.71 MSRP:$308.90You Save: $145.19 (48%)

Wagner® Vented Front Brake Rotor for 2009 GMC Savana 3500

PartNumber: BD126358EProduct Specifications- Notes: 6 Stud Wheel;with Black E-Coat on non-braking surface to prevent rust and corrosion;with 330mm Diameter Rotor

- Bolt Circle: 139.7mm (5.5")

- Lug Holes Quantity: 6

- Minimum Thickness: 28mm (1.102")

- Nominal Thickness: 29.97mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 329.82mm (12.99")

- Rotor Finish: With E-Shield™ Coating

- Rotor Height: 55.626mm (2.19")

- Rotor Material: Cast Iron

- Rotor Style: Plain

- UPC: 008536711070

- Part Description: 2009 GMC Savana 3500 Vented Front Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$72.42

Power Stop® PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair for 2009 GMC Savana 3500

PartNumber: AR8644XPRProduct Specifications- Notes: SRW; 91mm Tall Rear Discs

- Bolt Circle: 165.1mm (6.5")

- Driving Style: Performance / Racing

- Hub Hole Diameter: 122.68mm (4.83")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.51mm (0.65")

- Minimum Thickness: 27mm (1.06")

- Nominal Thickness: 29.21mm (1.15")

- Quantity: 2 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (13")

- Rotor Finish: Zinc Coated

- Rotor Height: 91.44mm (3.6")

- Rotor Material: Cast Iron

- Rotor Style: Drilled & Slotted

- Rotor Type: Vented

- Part Description: 2009 GMC Savana 3500 PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$261.58

Centric® GCX Plain 1-Piece Rear Brake Rotor for 2009 GMC Savana 3500

PartNumber: 320.66071Product Specifications- Notes: DRW

- UPC: 889590297218

- Part Description: 2009 GMC Savana 3500 GCX Plain 1-Piece Rear Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$76.78

DuraGo® Vented Rear Brake Rotor for 2009 GMC Savana 3500

PartNumber: BR900660Product Specifications- Notes: DRW

- Bolt Circle: 165.1mm (6.5")

- Center Hole Diameter: 123.2mm (4.85")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.3mm (0.64")

- Minimum Thickness: 38mm (1.50")

- Nominal Thickness: 40mm (1.57")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 345mm (13.58")

- Rotor Height: 146.2mm (5.76")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632172072

- Part Description: 2009 GMC Savana 3500 Vented Rear Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$76.97OEM (Genuine) 2009 GMC Savana 3500 Rotor

PartNumber: 15712803 Product Specifications

Product Specifications- Notes: 3/4 & 1 Ton, W/3.54 Gear Ratio

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 17.0 x 16.8 x 6.3 inches

- Item Weight: 30.20 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2009 GMC Savana 3500 Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | Base, LS, LT, SLE | 8 Cyl 4.8 L FLEX, 8 Cyl 4.8 L GAS, 8 Cyl 6.0 L CNG, 8 Cyl 6.0 L FLEX, 8 Cyl 6.0 L GAS, 8 Cyl 6.6 L DIESEL

$128.15 MSRP:$238.21You Save: $110.06 (47%)

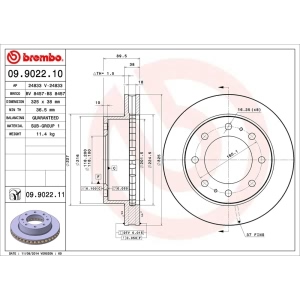

brembo® UV Coated Series Vented Front Brake Rotor for 2009 GMC Savana 3500

PartNumber: 09.9022.11Product Specifications- Notes: GVW 10,000 Lbs.; GVW 12,300 Lbs.; GVW 13,980 Lbs.; GVW 14,200 Lbs.

- Center Diameter: 118

- Coated: UV Coated

- Diameter (mm): 325

- Height: 89.4

- Material: Grey Cast Iron

- Minimum Thickness (mm): 36.5

- Nominal Thickness (mm): 38

- Number of Holes: 8

- Quantity: 8

- Solid Or Vented Type Rotor: vented

- Torque Spec(NM): 150

- Part Description: 2009 GMC Savana 3500 UV Coated Series Vented Front Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | Base | All Engines

$93.73

Power Stop® PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair for 2009 GMC Savana 3500

PartNumber: AR8643XPRProduct Specifications- Notes: SRW; 86mm Tall Rear Discs

- Bolt Circle: 165.1mm (6.5")

- Driving Style: Performance / Racing

- Hub Hole Diameter: 117.6mm (4.63")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.51mm (0.65")

- Minimum Thickness: 26.5mm (1.04")

- Nominal Thickness: 29.21mm (1.15")

- Quantity: 2 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (13")

- Rotor Finish: Zinc Coated

- Rotor Height: 85.85mm (3.38")

- Rotor Material: Cast Iron

- Rotor Style: Drilled & Slotted

- Rotor Type: Vented

- Part Description: 2009 GMC Savana 3500 PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$247.49

Centric® Premium Vented Rear Brake Rotor for 2009 GMC Savana 3500

PartNumber: 120.66044Product Specifications- Notes: 91mm Tall; SRW

- UPC: 805890036302

- Part Description: 2009 GMC Savana 3500 Premium Vented Rear Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$64.85

Bosch® QuietCast™ Premium Front Brake Rotor for 2009 GMC Savana 3500

PartNumber: 25010576Product Specifications- Notes: GVW 10000 over

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212083442

- Part Description: 2009 GMC Savana 3500 QuietCast™ Premium Front Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$77.20

DuraGo® Vented Front Brake Rotor for 2009 GMC Savana 3500

PartNumber: BR55062Product Specifications- Notes: GVW Over 9,600lb

- Bolt Circle: 165.1mm (6.5")

- Center Hole Diameter: 118.2mm (4.65")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.4mm (0.65")

- Minimum Thickness: 36.5mm (1.44")

- Nominal Thickness: 38.1mm (1.5")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 325.1mm (12.8")

- Rotor Height: 89.2mm (3.51")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632127096

- Part Description: 2009 GMC Savana 3500 Vented Front Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$54.80OEM (Genuine) 2009 GMC Savana 3500 Rotor

PartNumber: 15712801 Product Specifications

Product Specifications- Notes: Express, Savana; 1 Ton; Commercial Cutaway; W/O Dual Rear Wheels; 4.10 Ratio; W/Positraction

- Other Names: Rotor

- Item Dimensions: 16.1 x 15.8 x 5.6 inches

- Item Weight: 14.40 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2009 GMC Savana 3500 Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | Base, LS, LT | 8 Cyl 4.8 L FLEX, 8 Cyl 4.8 L GAS, 8 Cyl 6.0 L FLEX, 8 Cyl 6.0 L GAS, 8 Cyl 6.6 L DIESEL

$95.90 MSRP:$180.93You Save: $85.03 (47%)

brembo® UV Coated Series Front Brake Rotor for 2009 GMC Savana 3500

PartNumber: 09.C289.11Product Specifications- Notes: GVW 8,800lb; GVW 8,600lb; GVW 9,900lb; GVW 9,600lb ;GVW 8,600 Lbs.

- Coated: UV Coated

- Diameter (mm): 325

- Height: 89

- Material: Grey Cast Iron

- Minimum Thickness (mm): 36.5

- Nominal Thickness (mm): 38

- Number of Holes: 8

- Quantity: 8

- Solid Or Vented Type Rotor: vented

- Part Description: 2009 GMC Savana 3500 UV Coated Series Front Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | Base | All Engines

- 2009 GMC Savana 3500 | LS | All Engines

- 2009 GMC Savana 3500 | LT | All Engines

$86.04

Power Stop® PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair for 2009 GMC Savana 3500

PartNumber: AR8655XPRProduct Specifications- Bolt Circle: 165.1mm (6.5")

- Driving Style: Performance / Racing

- Hub Hole Diameter: 118.2mm (4.65")

- Lug Holes Quantity: 8

- Lug Holes Size: 416.56mm (16.4")

- Minimum Thickness: 36.5mm (1.44")

- Nominal Thickness: 38.1mm (1.5")

- Quantity: 2 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 325mm (12.8")

- Rotor Finish: Zinc Coated

- Rotor Height: 89mm (3.5")

- Rotor Material: Cast Iron

- Rotor Style: Drilled & Slotted

- Rotor Type: Vented

- Part Description: 2009 GMC Savana 3500 PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$234.84

Centric® Premium Vented Front Brake Rotor for 2009 GMC Savana 3500

PartNumber: 120.66059Product Specifications- Notes: DRW;SRW

- UPC: 805890208440

- Part Description: 2009 GMC Savana 3500 Premium Vented Front Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$68.15

DuraGo® Vented Rear Brake Rotor for 2009 GMC Savana 3500

PartNumber: BR900562Product Specifications- Notes: SRW; 4.63" Center Hole Dia

- Bolt Circle: 165mm (6.50")

- Center Hole Diameter: 117.6mm (4.63")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.5mm (0.65")

- Minimum Thickness: 27.5mm (1.08")

- Nominal Thickness: 29.3mm (1.15")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Height: 85.7mm (3.37")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632165142

- Part Description: 2009 GMC Savana 3500 Vented Rear Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$46.78OEM (Genuine) 2009 GMC Savana 3500 Rotor

PartNumber: 15127537 Product Specifications

Product Specifications- Notes: 3/4 & 1 Ton, W/3.42 Gear Ratio

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 16.2 x 16.1 x 5.6 inches

- Item Weight: 24.20 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2009 GMC Savana 3500 Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | Base, LS, LT | 4 Cyl 2.8 L DIESEL, 6 Cyl 4.3 L FLEX, 6 Cyl 4.3 L GAS, 8 Cyl 4.8 L FLEX, 8 Cyl 4.8 L GAS, 8 Cyl 6.0 L CNG, 8 Cyl 6.0 L FLEX, 8 Cyl 6.0 L GAS, 8 Cyl 6.6 L DIESEL, 8 Cyl 6.6 L GAS

$132.64 MSRP:$250.24You Save: $117.60 (47%)

Power Stop® PowerStop Evolution Coated Rotor for 2009 GMC Savana 3500

PartNumber: AR8655EVCProduct Specifications- Bolt Circle: 165.1mm (6.5")

- Hub Hole Diameter: 118.2mm (4.65")

- Lug Holes Quantity: 8

- Lug Holes Size: 416.56mm (16.4")

- Minimum Thickness: 36.5mm (1.44")

- Nominal Thickness: 38.1mm (1.5")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 325mm (12.8")

- Rotor Height: 89mm (3.5")

- Rotor Style: Plain

- Part Description: 2009 GMC Savana 3500 PowerStop Evolution Coated Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$90.48

Bosch® QuietCast™ Premium Vented Rear Brake Rotor for 2009 GMC Savana 3500

PartNumber: 25010560Product Specifications- Notes: Srw, 86mm high

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212083084

- Part Description: 2009 GMC Savana 3500 QuietCast™ Premium Vented Rear Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$64.87

Centric® GCX Plain 1-Piece Front Brake Rotor for 2009 GMC Savana 3500

PartNumber: 320.66059FProduct Specifications- Notes: DRW;SRW

- UPC: 889590393521

- Part Description: 2009 GMC Savana 3500 GCX Plain 1-Piece Front Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$67.91

DuraGo® Vented Rear Brake Rotor for 2009 GMC Savana 3500

PartNumber: BR55055Product Specifications- Notes: SRW; 4.84" Center Hole Dia

- Bolt Circle: 165.1mm (6.5")

- Center Hole Diameter: 122.9mm (4.84")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.5mm (0.65")

- Minimum Thickness: 27mm (1.06")

- Nominal Thickness: 29mm (1.14")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Height: 92.5mm (3.64")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632117165

- Part Description: 2009 GMC Savana 3500 Vented Rear Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$46.61

Power Stop® PowerStop Evolution Coated Rotor for 2009 GMC Savana 3500

PartNumber: AR8644EVCProduct Specifications- Notes: SRW; 91mm Tall Rear Discs

- Bolt Circle: 165.1mm (6.5")

- Hub Hole Diameter: 122.68mm (4.83")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.51mm (0.65")

- Minimum Thickness: 27mm (1.06")

- Nominal Thickness: 29.21mm (1.15")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Height: 91.44mm (3.6")

- Rotor Style: Plain

- Part Description: 2009 GMC Savana 3500 PowerStop Evolution Coated Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$79.40

Centric® Premium Vented Rear Brake Rotor for 2009 GMC Savana 3500

PartNumber: 120.66043Product Specifications- Notes: 86mm Tall; SRW

- UPC: 805890036296

- Part Description: 2009 GMC Savana 3500 Premium Vented Rear Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$61.59

DuraGo® Vented Front Brake Rotor for 2009 GMC Savana 3500

PartNumber: BR55072Product Specifications- Notes: GVW Under 9,600lb

- Bolt Circle: 165.1mm (6.5")

- Center Hole Diameter: 118.2mm (4.65")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.6mm (0.65")

- Minimum Thickness: 36.5mm (1.44")

- Nominal Thickness: 38mm (1.50")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 324.8mm (12.79")

- Rotor Height: 89.2mm (3.51")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632126280

- Part Description: 2009 GMC Savana 3500 Vented Front Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$42.38

Power Stop® PowerStop Evolution Coated Rotor for 2009 GMC Savana 3500

PartNumber: AR8643EVCProduct Specifications- Notes: SRW; 86mm Tall Rear Discs

- Bolt Circle: 165.1mm (6.5")

- Hub Hole Diameter: 117.6mm (4.63")

- Lug Holes Quantity: 8

- Lug Holes Size: 16.51mm (0.65")

- Minimum Thickness: 26.5mm (1.04")

- Nominal Thickness: 29.21mm (1.15")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Height: 85.85mm (3.38")

- Rotor Style: Plain

- Part Description: 2009 GMC Savana 3500 PowerStop Evolution Coated Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$75.10OEM (Genuine) 2009 GMC Savana 3500 Rotor

PartNumber: 84587921 Product Specifications

Product Specifications- Notes: Express, Savana; 1 Ton; Over 9600 Gvwr

- Other Names: Rotor

- Item Dimensions: 14.0 x 13.5 x 4.2 inches

- Item Weight: 29.90 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15733625

- Part Description: 2009 GMC Savana 3500 Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | Base, LS, LT, SLE | 4 Cyl 2.8 L DIESEL, 6 Cyl 4.3 L FLEX, 6 Cyl 4.3 L GAS, 8 Cyl 4.8 L FLEX, 8 Cyl 4.8 L GAS, 8 Cyl 6.0 L CNG, 8 Cyl 6.0 L FLEX, 8 Cyl 6.0 L GAS, 8 Cyl 6.6 L DIESEL, 8 Cyl 6.6 L GAS

$141.44 MSRP:$266.88You Save: $125.44 (48%)

Centric® Premium Vented Rear Brake Rotor for 2009 GMC Savana 3500

PartNumber: 125.66044Product Specifications- Notes: 91mm Tall; SRW

- UPC: 805890133308

- Part Description: 2009 GMC Savana 3500 Premium Vented Rear Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

$88.95

Bosch® QuietCast™ Premium Vented Front Brake Rotor for 2009 GMC Savana 3500

PartNumber: 25010556Product Specifications- Notes: OVER 9900lb GVW

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212083008

- Part Description: 2009 GMC Savana 3500 QuietCast™ Premium Vented Front Brake Rotor

Vehicle Fitment- 2009 GMC Savana 3500 | All Trims | All Engines

1-30 of 40 Results

< Previous

12

Next >FAQ for Brake Disc Repair

Q: What tool can be used to clean all rust and contaminants from the mating surface of the hub flange?

A:

You can use the J 42450-A.

By Bob

GM Specialist

01/11/2022Q: What tool can be used to remove the rotor from the hub assembly?

A:

You can use the J-46277 and the J 2619-01.

By Bob

GM Specialist

01/11/2022Q: Is it okay to leave the caliper/pads installed while cutting rotors using an on-car lathe?

A:

On-car lathes should never be used with the pads and calipers installed on the vehicle. The debris from cutting the rotors can contaminate the brake pads/calipers which can lead to other brake concerns and comebacks.

By Bob

GM Specialist

01/11/2022Q: What is the purpose of burnishing the brake pads and brake rotors?

A:

The purpose is to ensure that the braking surfaces are properly prepared after service has been performed on the disc brake system.

By Bob

GM Specialist

01/11/2022Q: What tool can be used to press the wheel studs from the hub and rotor assembly?

A:

You can use a hydraulic press.

By Bob

GM Specialist

01/11/2022Q: Which lathe is essential for performing brake work, the bench or the on-car?

A:

Dealers must have a well-maintained bench lathe and a well-maintained on-car lathe. These lathes need to be calibrated monthly. BOTH lathes are essential to providing quality brake service.

By Bob

GM Specialist

01/11/2022Q: What should you check before refinishing a brake rotor?

A:

You should first check the rotor for adequate thickness to allow the rotor to be refinished and remain above the minimum allowable thickness after refinishing specification.

By Bob

GM Specialist

01/11/2022Q: What tool can be used to clean all rust and contaminants from the inside diameter of the hat section of the brake rotor?

A:

You can use the J 41013.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque when installing the brake caliper bracket bolts?

A:

You can tighten to 300 Nm (221 lb-ft).

By Bob

GM Specialist

01/11/2022See more FAQs (4)