< Back ×

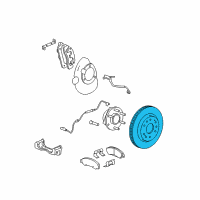

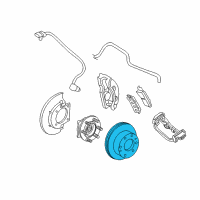

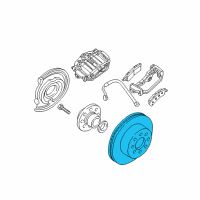

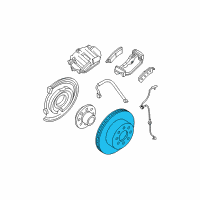

2009 Chevrolet Suburban 1500 Brake Disc

My Vehicle Change Vehicle

2009 Chevrolet Suburban 1500

< Back to View All

Brake Pads, Discs & Calipers

- Department

- Brands

- Prices

$58.64Product Specifications

$58.64Product Specifications- UPC: 805890324904

- Part Description: 2009 Chevrolet Suburban 1500 Premium Vented Front Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

$81.47Product Specifications

$81.47Product Specifications- Notes: 6 Stud Wheel;with 330mm Diameter Rotor;with Black E-Coat on non-braking surface to prevent rust and corrosion

- Bolt Circle: 139.7mm (5.5")

- Lug Holes Quantity: 6

- Minimum Thickness: 28mm (1.102")

- Nominal Thickness: 29.97mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 329.82mm (12.99")

- Rotor Finish: With E-Shield™ Coating

- Rotor Height: 55.626mm (2.19")

- Rotor Material: Cast Iron

- Rotor Style: Plain

- UPC: 008536711070

- Part Description: 2009 Chevrolet Suburban 1500 Vented Front Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

Power Stop® PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair for 2009 Chevrolet Suburban 1500

PartNumber: AR8654XPR$255.51Product Specifications- Bolt Circle: 140mm (5.5")

- Driving Style: Performance / Racing

- Hub Hole Diameter: 79mm (3.11")

- Lug Holes Quantity: 6

- Lug Holes Size: 16mm (0.63")

- Minimum Thickness: 28mm (1.1")

- Nominal Thickness: 29.97mm (1.18")

- Quantity: 2 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (13")

- Rotor Finish: Zinc Coated

- Rotor Height: 55mm (2.17")

- Rotor Material: Cast Iron

- Rotor Style: Drilled & Slotted

- Rotor Type: Vented

- Part Description: 2009 Chevrolet Suburban 1500 PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

$46.12Product Specifications

$46.12Product Specifications- Bolt Circle: 139.7mm (5.5")

- Center Hole Diameter: 78.6mm (3.09")

- Lug Holes Quantity: 6

- Lug Holes Size: 16mm (0.63")

- Minimum Thickness: 28mm (1.10")

- Nominal Thickness: 30.2mm (1.19")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Height: 55.6mm (2.19")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632149050

- Part Description: 2009 Chevrolet Suburban 1500 Vented Front Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

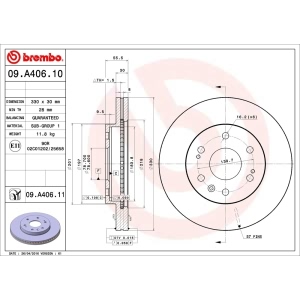

brembo® UV Coated Series Vented Front Brake Rotor for 2009 Chevrolet Suburban 1500

PartNumber: 09.A406.11$88.22Product Specifications- Coated: UV Coated

- Diameter (mm): 330

- Height: 56

- Material: Grey Cast Iron

- Minimum Thickness (mm): 28

- Nominal Thickness (mm): 30

- Number of Holes: 6

- Quantity: 6

- Solid Or Vented Type Rotor: vented

- Part Description: 2009 Chevrolet Suburban 1500 UV Coated Series Vented Front Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | LS | All Engines

- 2009 Chevrolet Suburban 1500 | LT | All Engines

- 2009 Chevrolet Suburban 1500 | LTZ | All Engines

- $136.54 MSRP:

$257.65You Save: $121.11 (48%)Product Specifications- Notes: 2WD, 1/2 Ton; 4WD, 1/2 Ton

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 13.5 x 13.8 x 3.5 inches

- Item Weight: 27.30 Pounds

- Fitment Type: Direct Replacement

- Replaces: 88963556, 25819670

- Part Description: 2009 Chevrolet Suburban 1500 Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | Base, LS, LT, LTZ, Z71 | 8 Cyl 5.3 L FLEX, 8 Cyl 5.3 L GAS, 8 Cyl 6.0 L GAS

$51.77Product Specifications

$51.77Product Specifications- UPC: 805890305750

- Part Description: 2009 Chevrolet Suburban 1500 Premium Vented Rear Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

Power Stop® PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair for 2009 Chevrolet Suburban 1500

PartNumber: AR8658XPR$251.71Product Specifications- Bolt Circle: 140mm (5.5")

- Driving Style: Performance / Racing

- Hub Hole Diameter: 78.5mm (3.09")

- Lug Holes Quantity: 6

- Lug Holes Size: 16.5mm (0.65")

- Minimum Thickness: 18.5mm (0.73")

- Nominal Thickness: 20mm (0.79")

- Quantity: 2 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Drum-in-Hat

- Rotor Diameter: 345mm (13.58")

- Rotor Finish: Zinc Coated

- Rotor Height: 85.4mm (3.36")

- Rotor Material: Cast Iron

- Rotor Style: Drilled & Slotted

- Rotor Type: Vented

- Part Description: 2009 Chevrolet Suburban 1500 PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

$41.24Product Specifications

$41.24Product Specifications- Bolt Circle: 139.7mm (5.5")

- Center Hole Diameter: 78.6mm (3.09")

- Lug Holes Quantity: 6

- Lug Holes Size: 16.4mm (0.65")

- Minimum Thickness: 18.5mm (0.73")

- Nominal Thickness: 20mm (0.79")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 345mm (13.58")

- Rotor Height: 85mm (3.35")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632160598

- Part Description: 2009 Chevrolet Suburban 1500 Vented Rear Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

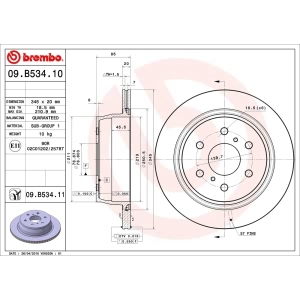

brembo® UV Coated Series Vented Rear Brake Rotor for 2009 Chevrolet Suburban 1500

PartNumber: 09.B534.11$81.22Product Specifications- Coated: UV Coated

- Diameter (mm): 345

- Height: 85

- Material: Grey Cast Iron

- Minimum Thickness (mm): 18.5

- Nominal Thickness (mm): 20

- Number of Holes: 6

- Quantity: 6

- Solid Or Vented Type Rotor: vented

- Part Description: 2009 Chevrolet Suburban 1500 UV Coated Series Vented Rear Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | LS | All Engines

- 2009 Chevrolet Suburban 1500 | LT | All Engines

- 2009 Chevrolet Suburban 1500 | LTZ | All Engines

- 2009 Chevrolet Suburban 1500 | Base | All Engines

$80.59Product Specifications

$80.59Product Specifications- Bolt Circle: 140.46mm (5.53")

- Hub Hole Diameter: 79mm (3.11")

- Lug Holes Quantity: 6

- Lug Holes Size: 16mm (0.63")

- Minimum Thickness: 28mm (1.1")

- Nominal Thickness: 29.97mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Height: 55mm (2.17")

- Rotor Style: Plain

- Part Description: 2009 Chevrolet Suburban 1500 PowerStop Evolution Coated Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

- $160.42 MSRP:

$302.70You Save: $142.28 (48%)Product Specifications- Notes: Yukon Xl, Suburban; 6.0l

- Other Names: Rotor

- Item Dimensions: 13.6 x 13.4 x 3.8 inches

- Item Weight: 27.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 18060215, 15718986

- Part Description: 2009 Chevrolet Suburban 1500 Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | Base, LS, LT, LTZ, Z71 | 8 Cyl 5.3 L FLEX, 8 Cyl 5.3 L GAS, 8 Cyl 6.0 L GAS

$79.38Product Specifications

$79.38Product Specifications- Bolt Circle: 139.7mm (5.5")

- Hub Hole Diameter: 78.5mm (3.09")

- Lug Holes Quantity: 6

- Lug Holes Size: 16.5mm (0.65")

- Minimum Thickness: 18.5mm (0.73")

- Nominal Thickness: 20mm (0.79")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Drum-in-Hat

- Rotor Diameter: 345mm (13.58")

- Rotor Height: 85.4mm (3.36")

- Rotor Style: Plain

- Part Description: 2009 Chevrolet Suburban 1500 PowerStop Evolution Coated Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

Bosch® QuietCast™ Premium Vented Rear Brake Rotor for 2009 Chevrolet Suburban 1500

PartNumber: 25010646$65.87Product Specifications- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212084760

- Part Description: 2009 Chevrolet Suburban 1500 QuietCast™ Premium Vented Rear Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

Bosch® QuietCast™ Premium Vented Front Brake Rotor for 2009 Chevrolet Suburban 1500

PartNumber: 25010621$81.26Product Specifications- Notes: DRW

- Lug Holes Quantity: 6

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Style: Plain

- UPC: 077212084371

- Part Description: 2009 Chevrolet Suburban 1500 QuietCast™ Premium Vented Front Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

- $175.27 MSRP:

$325.78You Save: $150.51 (47%)Product Specifications- Notes: Yukon Xl, Suburban; 6.0l

- Other Names: Rotor

- Item Dimensions: 17.0 x 16.8 x 6.3 inches

- Item Weight: 30.20 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2009 Chevrolet Suburban 1500 Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | LT, LTZ | 8 Cyl 6.0 L GAS

Product Specifications

Product Specifications- UPC: 889590253061

- Part Description: 2009 Chevrolet Suburban 1500 GCX Plain 1-Piece Front Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

Product Specifications

Product Specifications- UPC: 889590253108

- Part Description: 2009 Chevrolet Suburban 1500 GCX Plain 1-Piece Rear Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

Product Specifications

Product Specifications- UPC: 805890864561

- Part Description: 2009 Chevrolet Suburban 1500 Premium™ Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | All Trims | All Engines

- Product Specifications

- Notes: 1/2 Ton

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 15.1 x 15.2 x 5.3 inches

- Item Weight: 22.00 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25832103, 15792634

- Part Description: 2009 Chevrolet Suburban 1500 Rear Brake Rotor

Vehicle Fitment- 2009 Chevrolet Suburban 1500 | LS, LT, LTZ | 8 Cyl 5.3 L FLEX, 8 Cyl 5.3 L GAS, 8 Cyl 6.0 L GAS

FAQ for Brake Disc Repair

Q: What should be cautioned in installing Rear Brake Rotor (2500 Series)?

A:

If the rotor was removed and installed as part of a brake system repair, you should measure the assembled lateral runout (LRO) of the rotor to ensure the optimum performance of the disc brakes. If the rotor assembled LRO measurement exceeds the specification, you should bring the LRO to within specifications.

By Bob

GM Specialist

01/11/2022Q: What should be cautioned about in installing the Front Brake Rotor (1500 Series)?

A:

Any new rotor must have the protective coating removed from the friction surfaces before being placed in service. You should remove the protective coating using denatured alcohol or an equivalent brake cleaner, and wipe the surface clean with clean cloths. You can not use gasoline, kerosene, or other oil base solvents which may leave an oily residue. This residue is damaging to the brake lining and is flammable.

By Bob

GM Specialist

01/11/2022Q: What should we know about the Brake Pad and Rotor Burnishing?

A:

You should select a smooth road with little or no traffic, accelerate the vehicle to 48 km/h (30 mph), use care to avoid overheating the brakes while performing this step, use moderate to firm pressure, apply the brakes to bring the vehicle to a stop. You can not allow the brakes to lock, repeat steps 2 and 3 until approximately 20 stops have been completed, and allow sufficient cooling periods between stops to properly burnish the brake pads and rotors.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque when installing the brake caliper bracket bolts?

A:

The recommended torque is 200 Nm(148 lb-ft).

By Bob

GM Specialist

01/11/2022Q: What is the expected tip life for an on-car lathe?

A:

The geometry and composition of the Pro-Cut tips are designed for °single pass° cutting. When using the Pro-Cut the cutting depth should be set to take all material needed to get below rust grooves, eliminate all run-out and resurface the entire disc in a single pass. Cuts of 0.1016-0.381 mm (0.004-0.015 in) will provide the best surface finish and the optimal tip life. No °skim cut° or °finish cut° is needed. Failure to follow this procedure will shorten tip life. The Pro-cut tips will last between 7-12 cuts per corner. With three usable corners, a pair of tips is good for at least 21 cuts.

By Bob

GM Specialist

01/11/2022Q: What should be cautioned about Brake Rotor Assembled Lateral Runout Correction?

A:

Brake rotor thickness variation must be checked BEFORE checking for assembled lateral runout (LRO). Thickness variation exceeding the maximum acceptable level can cause brake pulsation. Brake rotor assembled lateral runout (LRO) exceeding the maximum allowable specification can cause thickness variation to develop in the brake rotor over time, usually between 4,800-11,300 km (3,000-7,000 mi). The indexing method of correcting assembled LRO is most effective when the LRO specification is only exceeded by a relatively small amount: 0.025-0.127 mm (0.001-0.005 in). The on-vehicle brake lathe method is used to bring the LRO to within specifications by compensating for LRO while refinishing the brake rotor.

By Bob

GM Specialist

01/11/2022Q: How to correct the Brake Rotor Assembled Lateral Runout-On Vehicle Lathe?

A:

You should ensure that the caliper and caliper bracket that is already being supported, are clear from contacting any rotating components, such as the brake rotor, remove the J-45101-100-washers and the lug nuts that were installed during the assembled LRO measurement procedure and/or the indexing correction procedure, inspect the mounting surface of the hub/axle flange and the brake rotor to ensure that no foreign particles or debris are remaining, set up the lathe, following the manufacturer's instructions, and refinish the brake rotor, following the brake lathe manufacturer's instructions. After each successive cut, inspect the brake rotor thickness. If at any time the brake rotor exceeds the minimum allowable thickness after refinishing specification, the brake rotor must be replaced. After refinishing the brake rotor, you should follow the brake lathe manufacturer's recommended speed setting for applying a non-directional finish and apply non-directional finish.

By Bob

GM Specialist

01/11/2022Q: To obtain the desired non-directional finish refinishing the brake rotor, what should you do?

A:

You should follow the brake lathe manufacturer's recommended speed setting for applying a non-directional finish. Using moderate pressure, you should apply the non-directional finish: if the lathe is equipped with a non-directional finishing tool, you should apply the finish with 120-grit aluminum oxide sandpaper. If the lathe is not equipped with a non-directional finishing tool, you should apply the finish with a sanding block and 150-grit aluminum oxide sandpaper. After applying a non-directional finish, you should clean each friction surface of the brake rotor with denatured alcohol, or an equivalent approved brake cleaner and wipe each friction surface using a clean shop towel to remove metal particles remaining from machining and repeat the cleaning process if necessary to remove all metal particles.

By Bob

GM Specialist

01/11/2022Q: What tools are required to replace Rear Brake Rotor (2500 Series)?

A:

J-41013-Rotor Resurfacing Kit and J-42450-A-Wheel Hub Resurfacing Kit.

By Bob

GM Specialist

01/11/2022Q: How to correct the Brake Rotor Assembled Lateral Runout-Indexing?

A:

You should remove the J-45101-100-washers and the lug nuts that were installed during the assembled LRO measurement procedure, inspect the mating surface of the hub/axle flange and the brake rotor to ensure that there are no foreign particles or debris remaining, index the brake rotor in a different orientation to the hub/axle flange, hold the rotor firmly in place against the hub/axle flange and install one of the J-45101-100-washers and one lug nut onto the upper-most wheel stud, install the remaining J-45101-100-washers and lug nuts onto the wheel studs and tighten the nuts firmly by hand in a star-pattern, tighten the lug nuts in a star-pattern to specification, measure the assembled LRO of the brake rotor and compare the amount of change between this measurement and the original measurement.

By Bob

GM Specialist

01/11/2022See more FAQs (10)