< Back ×

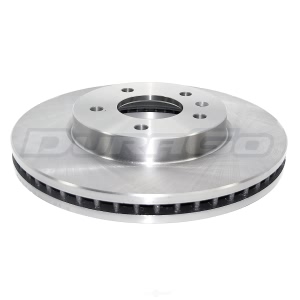

2009 Chevrolet Equinox Brake Disc

My Vehicle Change Vehicle

2009 Chevrolet Equinox

< Back to View All

Brake Pads, Discs & Calipers

- Department

- Brands

- Prices

$44.73Product Specifications

$44.73Product Specifications- UPC: 805890394426

- Part Description: 2009 Chevrolet Equinox Premium Vented Front Brake Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

$66.08Product Specifications

$66.08Product Specifications- Bolt Circle: 115mm (4.53")

- Hub Hole Diameter: 70.7mm (2.78")

- Lug Holes Quantity: 5

- Lug Holes Size: 322.58mm (12.7")

- Minimum Thickness: 27.4mm (1.08")

- Nominal Thickness: 29mm (1.14")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 296mm (11.65")

- Rotor Height: 51.6mm (2.03")

- Rotor Style: Plain

- Part Description: 2009 Chevrolet Equinox PowerStop Evolution Coated Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

$41.88Product Specifications

$41.88Product Specifications- Bolt Circle: 115mm (4.53")

- Center Hole Diameter: 70.7mm (2.78")

- Lug Holes Quantity: 5

- Lug Holes Size: 12.7mm (0.5")

- Minimum Thickness: 27.4mm (1.08")

- Nominal Thickness: 29mm (1.14")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 296mm (11.65")

- Rotor Height: 51.6mm (2.03")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632160673

- Part Description: 2009 Chevrolet Equinox Vented Front Brake Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

$38.27Product Specifications

$38.27Product Specifications- UPC: 805890394433

- Part Description: 2009 Chevrolet Equinox Premium Vented Rear Brake Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

$61.74Product Specifications

$61.74Product Specifications- Bolt Circle: 115mm (4.53")

- Hub Hole Diameter: 70.7mm (2.78")

- Lug Holes Quantity: 5

- Lug Holes Size: 322.58mm (12.7")

- Minimum Thickness: 18.4mm (0.72")

- Nominal Thickness: 20mm (0.79")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Drum-in-Hat

- Rotor Diameter: 303mm (11.93")

- Rotor Height: 71.8mm (2.83")

- Rotor Style: Plain

- Part Description: 2009 Chevrolet Equinox PowerStop Evolution Coated Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

- $109.51 MSRP:

$203.60You Save: $94.09 (47%)Product Specifications- Notes: 2 Wheel Drive, 2007-09 Disc Brake; All Wheel Drive, 2007-09 Disc Brake

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 4.2 x 13.3 x 12.6 inches

- Item Weight: 15.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25804046, 15223784

- Part Description: 2009 Chevrolet Equinox Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | LS, LT, LTZ, Sport | 6 Cyl 3.4 L GAS, 6 Cyl 3.6 L GAS

$37.68Product Specifications

$37.68Product Specifications- Bolt Circle: 115mm (4.53")

- Center Hole Diameter: 70.7mm (2.78")

- Lug Holes Quantity: 5

- Lug Holes Size: 12.7mm (0.5")

- Minimum Thickness: 18.4mm (0.72")

- Nominal Thickness: 20mm (0.79")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 303mm (11.93")

- Rotor Height: 71.6mm (2.82")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632160611

- Part Description: 2009 Chevrolet Equinox Vented Rear Brake Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

- $93.66 MSRP:

$176.73You Save: $83.07 (48%)Product Specifications- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 4.1 x 13.4 x 12.4 inches

- Item Weight: 21.10 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15837488, 25804049

- Part Description: 2009 Chevrolet Equinox Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | LS, LT, LTZ, Sport | 6 Cyl 3.4 L GAS, 6 Cyl 3.6 L GAS

Product Specifications

Product Specifications- UPC: 889590253115

- Part Description: 2009 Chevrolet Equinox GCX Plain 1-Piece Front Brake Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

Product Specifications

Product Specifications- UPC: 889590253122

- Part Description: 2009 Chevrolet Equinox GCX Plain 1-Piece Rear Brake Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

Product Specifications

Product Specifications- Bolt Circle: 115mm (4.53")

- Hub Hole Diameter: 70.7mm (2.78")

- Lug Holes Quantity: 5

- Lug Holes Size: 322.58mm (12.7")

- Minimum Thickness: 18.4mm (0.72")

- Nominal Thickness: 20mm (0.79")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Drum-in-Hat

- Rotor Diameter: 303mm (11.93")

- Rotor Height: 71.8mm (2.83")

- Rotor Style: Plain

- Part Description: 2009 Chevrolet Equinox AutoSpecialty Brake Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

Product Specifications

Product Specifications- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085194

- Part Description: 2009 Chevrolet Equinox QuietCast™ Premium Front Brake Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

Product Specifications

Product Specifications- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085323

- Part Description: 2009 Chevrolet Equinox QuietCast™ Premium Rear Brake Rotor

Vehicle Fitment- 2009 Chevrolet Equinox | All Trims | All Engines

FAQ for Brake Disc Repair

Q: What is the front brake rotor service procedure?

A:

Tighten the brake rotor retaining screws to 10 Nm.

By Bob

GM Specialist

01/11/2022Q: Which lathe is essential for performing brake work, the bench or the on-car?

A:

Dealers must have a well-maintained bench lathe and well maintained on-car lathe. These lathes need to be calibrated monthly. BOTH lathes are essential to providing quality brake service.

By Bob

GM Specialist

01/11/2022Q: What kind of special tools will be required in the Brake Rotor Refinishing procedure?

A:

The tools required include J-41013-Rotor Resurfacing Kit and J-42450-A-Wheel Hub Resurfacing Kit.

By Bob

GM Specialist

01/11/2022Q: What is the rear brake rotor service procedure?

A:

Tighten the brake rotor screw to 10 Nm, install a new brake rotor and adjust the park brake.

By Bob

GM Specialist

01/11/2022Q: Is it okay to leave the caliper/pads installed while cutting rotors using an on-car lathe?

A:

On-car lathes should never be used with the pads and calipers installed on the vehicle. The debris from cutting the rotors can contaminate the brake pads/calipers which can lead to other brake concerns and comebacks.

By Bob

GM Specialist

01/11/2022Q: How do on-car lathes react to Axle Float? Does the play affect the machining of the rotor, either surface finish or LRO?

A:

Because the Pro-Cut on-car lathe adjusts in a live mode while spinning the hub/rotor, the dynamics of a floating axle are effectively eliminated. Once the lathe is compensated, there is no difference in the cutting/surface finish and LRO are just the same as with a non-floating axle.

By Bob

GM Specialist

01/11/2022Q: How to obtain the desired non-directional finish after refinishing the brake rotor?

A:

First, follow the brake lathe manufacturer's recommended speed setting for applying a non-directional finish. Second, using moderate pressure, apply the non-directional finish: if the lathe is equipped with a non-directional finishing tool, apply the finish with 120-grit aluminum oxide sandpaper. if the lathe is not equipped with a non-directional finishing tool, apply the finish with a sanding block and 150-grit aluminum oxide sandpaper. Thirdly, after applying a non-directional finish, clean each friction surface of the brake rotor with denatured alcohol, or an equivalent approved brake cleaner and wipe each friction surface using a clean shop towel to remove metal particles remaining from machining. Repeat the cleaning process if necessary to remove all metal particles.

By Bob

GM Specialist

01/11/2022Q: What is the brake pad and rotor burnishing procedure?

A:

First, accelerate the vehicle to 30 mph and use pressure for the brakes to bring the vehicle to a stop.

By Bob

GM Specialist

01/11/2022See more FAQs (3)