< Back ×

2008 Chevrolet Impala A/C Hose

My Vehicle Change Vehicle

2008 Chevrolet Impala

< Back to View All

A/C & Heating

- Department

- Prices

- $103.05 MSRP:

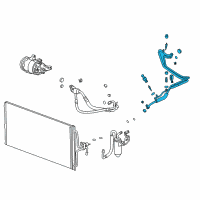

$194.47You Save: $91.42 (48%)Product Specifications- Other Names: AC Tube, Evaporator Tube

- Item Dimensions: 41.6 x 16.3 x 13.0 inches

- Item Weight: 3.30 Pounds

- Fitment Type: Direct Replacement

- Replaces: 20763820, 10346642, 15258005, 25886946

- Part Description: 2008 Chevrolet Impala Evaporator Tube

Vehicle Fitment- 2008 Chevrolet Impala | 50th Anniversary Edition, LS, LT, LTZ, Police, SS | 6 Cyl 3.5 L FLEX, 6 Cyl 3.5 L GAS, 6 Cyl 3.9 L FLEX, 6 Cyl 3.9 L GAS, 8 Cyl 5.3 L GAS

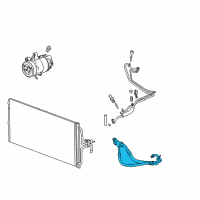

- $107.39 MSRP:

$202.63You Save: $95.24 (48%)Product Specifications- Notes: 3.5, 3.9 Liter; Impala, Monte Carlo; Federal; 3.5l, 3.9l

- Other Names: AC Hose, Compressor & Condenser Hose

- Item Dimensions: 31.0 x 11.4 x 8.7 inches

- Item Weight: 1.70 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2008 Chevrolet Impala Compressor & Condenser Hose

Vehicle Fitment- 2008 Chevrolet Impala | 50th Anniversary Edition, LS, LT, LTZ, Police, SS | 6 Cyl 3.5 L FLEX, 6 Cyl 3.5 L GAS, 6 Cyl 3.9 L FLEX, 6 Cyl 3.9 L GAS, 8 Cyl 5.3 L GAS

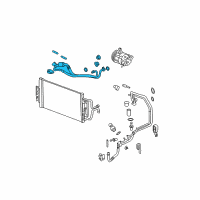

- Product Specifications

- Notes: 5.3 Liter; Impala, Monte Carlo; Federal; 5.3l

- Item Dimensions: 31.9 x 9.6 x 5.7 inches

- Item Weight: 1.70 Pounds

- Fitment Type: Direct Replacement

- Replaces: 10346641

- Part Description: 2008 Chevrolet Impala Hose Asm-A/C Compressor & Condenser

Vehicle Fitment- 2008 Chevrolet Impala | SS | 8 Cyl 5.3 L GAS

- Product Specifications

- Notes: Impala, Monte Carlo; California

- Other Names: Compressor & Condenser Hose

- Item Dimensions: 32.8 x 6.8 x 5.8 inches

- Item Weight: 1.90 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2008 Chevrolet Impala Hose Asm-A/C Compressor & Condenser

Vehicle Fitment- 2008 Chevrolet Impala | 50th Anniversary Edition, LS, LT, LTZ, Police, SS | 6 Cyl 3.5 L FLEX, 6 Cyl 3.5 L GAS, 6 Cyl 3.9 L FLEX, 8 Cyl 5.3 L GAS

FAQ for A/C Hose Repair

Q: Which component should the A/C coupling assembly be latched to?

A:

You may need to ensure that the A/C coupling assembly is latched securely to the A/C refrigerant component.

By Bob

GM Specialist

28/10/2022Q: What should be noticed when removing the air conditioning line/tube connector?

A:

You will need to apply light pressure between the two halves of the coupling to prevent the locking tabs from reengaging when separating the A/C coupling assembly.

By Bob

GM Specialist

28/10/2022Q: What's the recommended torque for the A/C compressor nut and evaporator tube?

A:

The recommended torque is 17 N.m (121.5 lb in).

By Bob

GM Specialist

28/10/2022Q: How to prevent the A/C line from twisting while torquing the A/C line nut?

A:

You can use a 20 mm wrench or pliers to hold the A/C condenser block fitting.

By Bob

GM Specialist

28/10/2022Q: What should you be careful about when installing the air conditioning line/tube connector?

A:

You shall inspect the A/C coupling assembly locking tabs for damage or wear and replace the A/C coupler assembly if any conditions exist.

By Bob

GM Specialist

28/10/2022Q: What's the recommended torque for the A/C compressor hose nut?

A:

The recommended torque is 17 N.m (121.5 lb in).

By Bob

GM Specialist

28/10/2022Q: What is the tip for replacing the suction screen?

A:

You can remove the suction screen from the A/C compressor suction port using a flat-bladed tool or pick.

By Bob

GM Specialist

28/10/2022Q: What's the recommended torque for the A/C compressor nut and condenser?

A:

The recommended torque is 17 N.m (121.5 lb in).

By Bob

GM Specialist

28/10/2022See more FAQs (3)