< Back ×

My Vehicle Change Vehicle

2008 Cadillac STS

< Back to View All

Control Arms & Suspension Rods

- Department

- Adjustable

- Ball Joint Included

- Bushing Material

- Bushings Included

- Control Arm Material

- Brands

- Prices

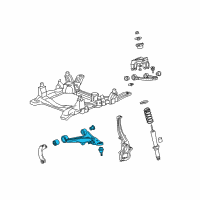

OEM (Genuine) 2008 Cadillac STS Lower Control Arm

PartNumber: 25862781 Product Specifications

Product Specifications- Notes: Sts, Sts-V; Left; W/AWD; Sts, W/AWD

- Location: Driver Side

- Other Names: Lower Control Arm

- Item Dimensions: 5.9 x 18.7 x 16.1 inches

- Item Weight: 13.70 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25765776, 15806921, 25764671, 15270101, 15921069

- Part Description: 2008 Cadillac STS Lower Control Arm

Vehicle Fitment- 2008 Cadillac STS | Base, Platinum | 6 Cyl 3.6 L GAS, 8 Cyl 4.6 L GAS

$245.87 MSRP:$406.96You Save: $161.09 (40%)

Dorman® Front Passenger Side Lower Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 522-612Product Specifications- Grade Type: Standard Replacement

- OE Part Number: 15921068

- UPC: 019495904380

- Part Description: 2008 Cadillac STS Front Passenger Side Lower Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

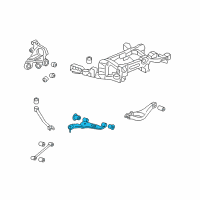

$213.71OEM (Genuine) 2008 Cadillac STS Upper Control Arm

PartNumber: 19177211 Product Specifications

Product Specifications- Notes: Sts; W/O Variable Time Damping; Left; Sts, W/O AWD; Sts, W/AWD

- Location: Driver Side

- Other Names: Upper Control Arm

- Item Dimensions: 13.6 x 12.6 x 12.8 inches

- Item Weight: 13.30 Pounds

- Fitment Type: Direct Replacement

- Replaces: 88964550

- Part Description: 2008 Cadillac STS Upper Control Arm

Vehicle Fitment- 2008 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$294.42 MSRP:$469.58You Save: $175.16 (38%)

Delphi® Rear Passenger Side Upper Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: TC7368Product Specifications- Item Grade: Standard Replacement

- UPC: 689604351017

- Part Description: 2008 Cadillac STS Rear Passenger Side Upper Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | 8 Cyl 4.6L

- 2008 Cadillac STS | All Trims | 6 Cyl 3.6L

- 2008 Cadillac STS | All Trims | 8 Cyl 4.4L

$161.59

Mevotech® Supreme Front Passenger Side Lower Non Adjustable Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: CMS501120Product Specifications- Notes: Supreme, complete arm w/ball joint, corrosion resistant, hardware included and greaseable for increased durability

- Ball Joint Stud Type: Threaded

- Bushing Material: Natural Rubber

- Finish: Silver

- Grease Fitting: Yes

- Length: 17.4"

- Material: Cast Steel

- Pre-Grease: Yes

- Required Quantity: 1 per Vehicle

- UPC: 669719209069

- Width: 15.4"

- Part Description: 2008 Cadillac STS Supreme Front Passenger Side Lower Non Adjustable Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

$221.47

Dorman® Front Driver Side Lower Non Adjustable Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 521-021Product Specifications- Attachment Type: Pressed

- Ball Joint Stud Type: Threaded

- Control Arm Type: Casting/Forged

- Grade Type: Standard Replacement

- Material: Aluminum

- OE Part Number: 15921069, 25862781

- Pre-Grease: Yes

- UPC: 019495261940

- Part Description: 2008 Cadillac STS Front Driver Side Lower Non Adjustable Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

$181.28OEM (Genuine) 2008 Cadillac STS Upper Control Arm

PartNumber: 19168536 Product Specifications

Product Specifications- Notes: Sts; W/O Variable Time Damping; Right; Sts, W/O AWD; Sts, W/AWD

- Location: Passenger Side

- Other Names: Upper Control Arm

- Item Dimensions: 13.6 x 13.1 x 13.0 inches

- Item Weight: 12.50 Pounds

- Fitment Type: Direct Replacement

- Replaces: 88964551

- Part Description: 2008 Cadillac STS Upper Control Arm

Vehicle Fitment- 2008 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$284.39 MSRP:$470.71You Save: $186.32 (40%)

Mevotech® Supreme Front Driver Side Lower Non Adjustable Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: CMS501119Product Specifications- Notes: Supreme, complete arm w/ball joint, corrosion resistant, hardware included and greaseable for increased durability

- Adjustable: No

- Ball Joint Mounting Type: Unitized

- Ball Joint Stud Type: Threaded

- Bearing Type: Sintered Metal

- Bushing Material: Natural Rubber

- Bushings Included: Yes

- Control Arm Color: Silver

- Control Arm Material: Cast Aluminium

- Control Arm Maximum Length: 17.36

- Control Arm Maximum Width: 15.28

- Finish: Corrosion Resistant

- Greasable: Yes

- Grease Fitting Included: Yes

- Mounting Hardware Included: Yes

- Pre-Greased: Yes

- UPC: 669719209052

- Part Description: 2008 Cadillac STS Supreme Front Driver Side Lower Non Adjustable Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

$202.39

Dorman® Front Passenger Side Lower Non Adjustable Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 521-022Product Specifications- Attachment Type: Pressed

- Ball Joint Stud Type: Threaded

- Control Arm Type: Casting/Forged

- Grade Type: Standard Replacement

- Material: Aluminum

- OE Part Number: 15921070, 25862782

- Pre-Grease: Yes

- UPC: 019495261957

- Part Description: 2008 Cadillac STS Front Passenger Side Lower Non Adjustable Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

$181.28OEM (Genuine) 2008 Cadillac STS Upper Control Arm

PartNumber: 15267619 Product Specifications

Product Specifications- Notes: Sts, Sts-V; Left

- Location: Driver Side

- Other Names: Upper Control Arm

- Item Dimensions: 5.7 x 19.2 x 18.4 inches

- Item Weight: 9.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25766117

- Part Description: 2008 Cadillac STS Upper Control Arm

Vehicle Fitment- 2008 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$120.81 MSRP:$199.96You Save: $79.15 (40%)

Mevotech® Supreme Rear Driver Side Upper Non Adjustable Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: CMS501131Product Specifications- Notes: Supreme, corrosion resistant for increased durability.

- Adjustable: No

- Ball Joint Mounting Type: Press In

- Ball Joint Stud Type: Threaded

- Bushing Material: Natural Rubber

- Bushings Included: Yes

- Control Arm Color: Silver

- Control Arm Material: Cast Aluminium

- Control Arm Maximum Length: 15.6

- Control Arm Maximum Width: 13.9

- Finish: Corrosion Resistant

- Pre-Greased: Yes

- UPC: 669719209090

- Part Description: 2008 Cadillac STS Supreme Rear Driver Side Upper Non Adjustable Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

$185.64

Dorman® Rear Passenger Side Upper Non Adjustable Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 522-488Product Specifications- Attachment Type: Pressed

- Ball Joint Stud Type: Threaded

- Control Arm Type: Casting/Forged

- Grade Type: Standard Replacement

- Material: Steel

- OE Part Number: 15267620, 25766118

- Pre-Grease: Yes

- UPC: 019495902911

- Part Description: 2008 Cadillac STS Rear Passenger Side Upper Non Adjustable Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

$141.02OEM (Genuine) 2008 Cadillac STS Upper Control Arm

PartNumber: 15267620 Product Specifications

Product Specifications- Notes: Sts, Sts-V; Right

- Location: Passenger Side

- Other Names: Upper Control Arm

- Item Dimensions: 4.6 x 17.2 x 16.5 inches

- Item Weight: 9.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25766118

- Part Description: 2008 Cadillac STS Upper Control Arm

Vehicle Fitment- 2008 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$124.16 MSRP:$198.03You Save: $73.87 (38%)

Mevotech® Supreme Rear Passenger Side Upper Non Adjustable Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: CMS501132Product Specifications- Notes: Supreme, corrosion resistant for increased durability.

- Ball Joint Mounting Type: Press In

- Ball Joint Stud Type: Threaded

- Bushing Material: Natural Rubber

- Finish: Silver

- Length: 16.5"

- Material: Cast Aluminum

- Pre-Grease: Yes

- Required Quantity: 1 per Vehicle

- UPC: 669719209106

- Width: 13.95"

- Part Description: 2008 Cadillac STS Supreme Rear Passenger Side Upper Non Adjustable Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

$185.64

Dorman® Rear Driver Side Upper Non Adjustable Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 522-487Product Specifications- Attachment Type: Pressed

- Ball Joint Stud Type: Threaded

- Control Arm Type: Casting/Forged

- Grade Type: Standard Replacement

- Material: Steel

- OE Part Number: 15267619, 25766117

- Pre-Grease: Yes

- UPC: 019495902904

- Part Description: 2008 Cadillac STS Rear Driver Side Upper Non Adjustable Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

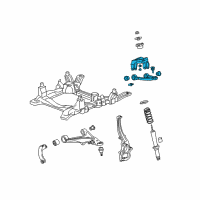

$130.28OEM (Genuine) 2008 Cadillac STS Lower Control Arm

PartNumber: 15921067 Product Specifications

Product Specifications- Notes: Sts, Sts-V; Left; W/O AWD; Sts, W/O AWD; Sts-V

- Location: Driver Side

- Other Names: Lower Control Arm

- Item Dimensions: 18.5 x 15.9 x 6.2 inches

- Item Weight: 13.30 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25768791, 15806919, 15270105, 15829325

- Part Description: 2008 Cadillac STS Lower Control Arm

Vehicle Fitment- 2008 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$257.02 MSRP:$409.93You Save: $152.91 (38%)

Mevotech® Supreme Front Driver Side Upper Non Adjustable Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: CMS501121Product Specifications- Notes: Supreme, hardware included and corrosion resistant for increased durability.; w/ MagneRide

- Ball Joint Mounting Type: Press In

- Ball Joint Stud Type: Threaded

- Bushing Material: Natural Rubber

- Finish: Silver

- Length: 11.5"

- Material: Cast Aluminum

- Pre-Grease: Yes

- Required Quantity: 1 per Vehicle

- UPC: 669719070874

- Width: 11.5"

- Part Description: 2008 Cadillac STS Supreme Front Driver Side Upper Non Adjustable Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

$104.62OEM (Genuine) 2008 Cadillac STS Upper Control Arm

PartNumber: 19207759 Product Specifications

Product Specifications- Notes: Sts-V; Left; Sts-V

- Location: Passenger Side

- Other Names: Upper Control Arm

- Item Dimensions: 14.0 x 13.0 x 9.9 inches

- Item Weight: 11.20 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25847957

- Part Description: 2008 Cadillac STS Upper Control Arm

Vehicle Fitment- 2008 Cadillac STS | V | 8 Cyl 4.4 L GAS

$266.05 MSRP:$440.35You Save: $174.30 (40%)

Mevotech® Supreme Front Passenger Side Upper Non Adjustable Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: CMS501122Product Specifications- Notes: Supreme, hardware included and corrosion resistant for increased durability.; w/ MagneRide

- Adjustable: No

- Ball Joint Mounting Type: Press In

- Ball Joint Stud Type: Threaded

- Bushing Material: Natural Rubber

- Bushings Included: Yes

- Control Arm Color: Silver

- Control Arm Material: Cast Aluminium

- Control Arm Maximum Length: 11.5

- Control Arm Maximum Width: 11.5

- Finish: Corrosion Resistant

- Mounting Hardware Included: Yes

- Pre-Greased: Yes

- UPC: 669719070881

- Part Description: 2008 Cadillac STS Supreme Front Passenger Side Upper Non Adjustable Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

$104.62OEM (Genuine) 2008 Cadillac STS Upper Control Arm

PartNumber: 19207760 Product Specifications

Product Specifications- Notes: Sts-V; Right; Sts-V

- Location: Driver Side

- Other Names: Upper Control Arm

- Item Dimensions: 14.0 x 12.7 x 9.6 inches

- Item Weight: 11.30 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25847958

- Part Description: 2008 Cadillac STS Upper Control Arm

Vehicle Fitment- 2008 Cadillac STS | V | 8 Cyl 4.4 L GAS

$161.83 MSRP:$258.12You Save: $96.29 (38%)OEM (Genuine) 2008 Cadillac STS Lower Control Arm

PartNumber: 15921068 Product Specifications

Product Specifications- Notes: Sts, Sts-V; Right; W/O AWD; Sts, W/O AWD; Sts-V

- Location: Passenger Side

- Other Names: Lower Control Arm

- Item Dimensions: 19.1 x 15.7 x 6.4 inches

- Item Weight: 13.10 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25768792, 15806920, 15829324, 15270106

- Part Description: 2008 Cadillac STS Lower Control Arm

Vehicle Fitment- 2008 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$245.27 MSRP:$405.99You Save: $160.72 (40%)OEM (Genuine) 2008 Cadillac STS Upper Control Arm

PartNumber: 19181784 Product Specifications

Product Specifications- Notes: Sts; W/Variable Time Damping; Left

- Other Names: Upper Control Arm

- Item Dimensions: 13.7 x 12.7 x 9.6 inches

- Item Weight: 12.20 Pounds

- Fitment Type: Direct Replacement

- Replaces: 88955491

- Part Description: 2008 Cadillac STS Upper Control Arm

Vehicle Fitment- 2008 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$79.49 MSRP:$131.58You Save: $52.09 (40%)

Centric® Premium™ Rear Driver Side Upper Control Arm and Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 622.62841Product Specifications- UPC: 805890403852

- Part Description: 2008 Cadillac STS Premium™ Rear Driver Side Upper Control Arm and Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

$132.43

Centric® Premium™ Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 622.62025Product Specifications- UPC: 889590434255

- Part Description: 2008 Cadillac STS Premium™ Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

Centric® Premium™ Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 622.62026Product Specifications- UPC: 889590434262

- Part Description: 2008 Cadillac STS Premium™ Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

Centric® Premium™ Front Driver Side Lower Control Arm and Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 622.62072Product Specifications- UPC: 805890541059

- Part Description: 2008 Cadillac STS Premium™ Front Driver Side Lower Control Arm and Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

Centric® Premium™ Front Passenger Side Lower Control Arm and Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 622.62073Product Specifications- UPC: 889590434279

- Part Description: 2008 Cadillac STS Premium™ Front Passenger Side Lower Control Arm and Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

Centric® Premium™ Rear Passenger Side Upper Control Arm and Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 622.62842Product Specifications- UPC: 805890403869

- Part Description: 2008 Cadillac STS Premium™ Rear Passenger Side Upper Control Arm and Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

Centric® Premium™ Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 622.62843Product Specifications- UPC: 805890403876

- Part Description: 2008 Cadillac STS Premium™ Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

Centric® Premium™ Control Arm And Ball Joint Assembly for 2008 Cadillac STS

PartNumber: 622.62844Product Specifications- UPC: 805890403883

- Part Description: 2008 Cadillac STS Premium™ Control Arm And Ball Joint Assembly

Vehicle Fitment- 2008 Cadillac STS | All Trims | All Engines

1-30 of 34 Results

< Previous

12

Next >FAQ for Control Arm Repair

Q: What should be noticed in the installation procedure for Upper Control Arm?

A:

You should loosely install all fasteners before tightening.

By Bob

GM Specialist

29/10/2022Q: What is the recommended torque for the fasteners?

A:

You should tighten the lower control arm to the frame bolt to 135 N.m (100 lb-ft), tighten the lower control arm to the frame nut to 135 N.m (100 lb-ft), tighten the lower control arm to the knuckle bolt to 160 N.m (118 lb-ft).

By Bob

GM Specialist

29/10/2022Q: What should be noticed in the removal procedure for Upper Control Arm?

A:

You should use hand tools to keep the ball stud from rotating. If air tools are used and the stud is allowed to rotate, damage to the ball stud and/or stud mounting hole may occur.

By Bob

GM Specialist

29/10/2022Q: What tool is required in the procedure for Lower Control Arm (AWD)?

A:

J43631 Ball Joint Separator is required in the procedure for Lower Control Arm (AWD).

By Bob

GM Specialist

29/10/2022Q: What should be noticed in the removal procedure for Lower Control Arm (AWD)?

A:

You should raise the power steering gear to provide clearance when removing the rear lower control arm to frame the retaining bolt.

By Bob

GM Specialist

29/10/2022Q: What should be noticed when installing the lower control arm to the vehicle?

A:

You should loosely install all fasteners before tightening.

By Bob

GM Specialist

29/10/2022Q: What is the recommended torque for the lower control arm to cradle nuts?

A:

The recommended torque is 135 N.m (96 lb-ft).

By Bob

GM Specialist

29/10/2022Q: What tool is required in the replacement procedure for Lower Control Arm (RWD)?

A:

J42188 Ball Joint Separator is required in the replacement procedure for Lower Control Arm (RWD).

By Bob

GM Specialist

29/10/2022See more FAQs (3)