< Back ×

My Vehicle Change Vehicle

2008 Cadillac CTS

< Back to View All

Brake Pads, Discs & Calipers

- Department

- Brands

- Prices

Power Stop® PowerStop Evolution Coated Rotor for 2008 Cadillac CTS

PartNumber: AR82125EVCProduct Specifications- Notes: Sport & Perf Pkg (FE3); 345mm Front Rotor; 339mm Rear Rotor

- Bolt Circle: 120mm (4.72")

- Hub Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 5

- Lug Holes Size: 421.64mm (16.6")

- Minimum Thickness: 28.5mm (1.12")

- Nominal Thickness: 30mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 345mm (13.58")

- Rotor Height: 51mm (2.01")

- Rotor Style: Plain

- Part Description: PowerStop Evolution Coated Rotor

$90.12OEM (Genuine) 2008 Cadillac CTS Rotor

PartNumber: 20808621 Product Specifications

Product Specifications- Notes: Cts, W/O Heavy Duty

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 4.1 x 15.9 x 14.3 inches

- Item Weight: 17.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15267107

- Part Description: Rotor

$77.47 MSRP:$146.17You Save: $68.70 (48%)

DuraGo® Vented Front Brake Rotor for 2008 Cadillac CTS

PartNumber: BR900508Product Specifications- Notes: HD Brakes

- Bolt Circle: 120mm (4.72")

- Center Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 5

- Lug Holes Size: 16.4mm (0.65")

- Minimum Thickness: 28.5mm (1.12")

- Nominal Thickness: 30mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 345mm (13.58")

- Rotor Height: 51mm (2.01")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632164930

- Part Description: Vented Front Brake Rotor

$50.28

Centric® Premium Vented Front Brake Rotor for 2008 Cadillac CTS

PartNumber: 120.62140Product Specifications- Notes: 339mm Rear Disc; 345mm Front Disc; HD Brakes (J55)

- UPC: 805890911241

- Part Description: Premium Vented Front Brake Rotor

$88.14

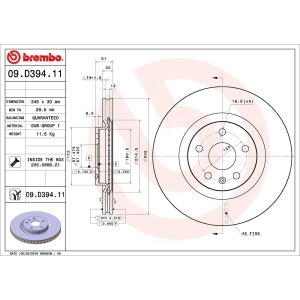

brembo® UV Coated Series Vented Front Brake Rotor for 2008 Cadillac CTS

PartNumber: 09.D394.11Product Specifications- Notes: Heavy Duty Brakes

- Center Diameter: 67.4

- Coated: UV Coated

- Diameter (mm): 345

- Height: 51

- Material: Grey Cast Iron

- Minimum Thickness (mm): 28.5

- Nominal Thickness (mm): 30

- Number of Holes: 5

- Quantity: 5

- Solid Or Vented Type Rotor: vented

- Part Description: UV Coated Series Vented Front Brake Rotor

$74.65

Power Stop® PowerStop Evolution Coated Rotor for 2008 Cadillac CTS

PartNumber: AR82124EVCProduct Specifications- Notes: Except Sport & Perf Pkg; 315mm Front Rotor; 315mm Rear Rotor

- Bolt Circle: 120mm (4.72")

- Hub Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 5

- Lug Holes Size: 421.64mm (16.6")

- Minimum Thickness: 28.5mm (1.12")

- Nominal Thickness: 30mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 316mm (12.44")

- Rotor Height: 51mm (2.01")

- Rotor Style: Plain

- Part Description: PowerStop Evolution Coated Rotor

$71.76OEM (Genuine) 2008 Cadillac CTS Rotor

PartNumber: 20808622 Product Specifications

Product Specifications- Notes: Cts, W/Heavy Duty

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 3.1 x 15.2 x 14.6 inches

- Item Weight: 20.00 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15267108

- Part Description: Rotor

$77.39 MSRP:$146.04You Save: $68.65 (48%)

DuraGo® Vented Front Brake Rotor for 2008 Cadillac CTS

PartNumber: BR900504Product Specifications- Notes: Exc HD Brakes

- Bolt Circle: 120mm (4.72")

- Center Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 5

- Lug Holes Size: 16.6mm (0.65")

- Minimum Thickness: 28.5mm (1.12")

- Nominal Thickness: 30mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 316mm (12.44")

- Rotor Height: 51mm (2.01")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632164916

- Part Description: Vented Front Brake Rotor

$46.08

Centric® Premium Vented Front Brake Rotor for 2008 Cadillac CTS

PartNumber: 120.62106Product Specifications- Notes: 315mm Front & Rear Disc; Std Brakes (JE5)

- UPC: 805890433132

- Part Description: Premium Vented Front Brake Rotor

$59.63

Power Stop® PowerStop Evolution Coated Rotor for 2008 Cadillac CTS

PartNumber: AR82156EVCProduct Specifications- Notes: Sport & Perf Pkg (FE3); 345mm Front Rotor; 339mm Rear Rotor

- Bolt Circle: 120mm (4.72")

- Hub Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 5+1

- Lug Holes Size: 421.64mm (16.6")

- Minimum Thickness: 21.5mm (0.85")

- Nominal Thickness: 23mm (0.91")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Drum-in-Hat

- Rotor Diameter: 339mm (13.35")

- Rotor Height: 48mm (1.89")

- Rotor Style: Plain

- Part Description: PowerStop Evolution Coated Rotor

$62.79

DuraGo® Vented Rear Brake Rotor for 2008 Cadillac CTS

PartNumber: BR900510Product Specifications- Notes: HD Brakes; 18" Whls

- Bolt Circle: 120mm (4.72")

- Center Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 5

- Lug Holes Size: 16.6mm (0.65")

- Minimum Thickness: 21.5mm (0.85")

- Nominal Thickness: 23mm (0.91")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 339mm (13.35")

- Rotor Height: 48mm (1.89")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632164947

- Part Description: Vented Rear Brake Rotor

$39.39

Power Stop® PowerStop Evolution Coated Rotor for 2008 Cadillac CTS

PartNumber: AR82127EVCProduct Specifications- Notes: 315mm; Except Sport & Perf Pkg

- Bolt Circle: 120mm (4.72")

- Hub Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 5

- Lug Holes Size: 421.64mm (16.6")

- Minimum Thickness: 21.5mm (0.85")

- Nominal Thickness: 23mm (0.91")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Drum-in-Hat

- Rotor Diameter: 315mm (12.4")

- Rotor Height: 48mm (1.89")

- Rotor Style: Plain

- Part Description: PowerStop Evolution Coated Rotor

$60.43

DuraGo® Vented Rear Brake Rotor for 2008 Cadillac CTS

PartNumber: BR900506Product Specifications- Notes: Exc HD Brakes;HD Brakes; 17" Whls

- Bolt Circle: 120mm (4.72")

- Center Hole Diameter: 67.4mm (2.65")

- Lug Holes Quantity: 5

- Lug Holes Size: 16.6mm (0.65")

- Minimum Thickness: 21.5mm (0.85")

- Nominal Thickness: 23mm (0.91")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 315mm (12.4")

- Rotor Height: 48mm (1.89")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632164923

- Part Description: Vented Rear Brake Rotor

$32.52

Centric® GCX Plain 1-Piece Front Brake Rotor for 2008 Cadillac CTS

PartNumber: 320.62106Product Specifications- Notes: 315mm Front & Rear Disc; Std Brakes (JE5)

- UPC: 889590301885

- Part Description: GCX Plain 1-Piece Front Brake Rotor

$42.20

Centric® Premium Vented Rear Brake Rotor for 2008 Cadillac CTS

PartNumber: 120.62105Product Specifications- Notes: 315mm Front & Rear Disc; Std Brakes (JE5)

- UPC: 805890433095

- Part Description: Premium Vented Rear Brake Rotor

$45.96

Centric® Premium Vented Rear Brake Rotor for 2008 Cadillac CTS

PartNumber: 120.62107Product Specifications- Notes: 339mm Rear Disc; 345mm Front Disc; HD Brakes (J55)

- UPC: 805890433156

- Part Description: Premium Vented Rear Brake Rotor

$52.90OEM (Genuine) 2008 Cadillac CTS Rotor

PartNumber: 25946317 Product Specifications

Product Specifications- Notes: W/O AWD, W/Heavy Duty; W/AWD, W/Heavy Duty

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 16.4 x 16.2 x 5.8 inches

- Item Weight: 26.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15267103

- Part Description: Rotor

Centric® GCX Rotor With Partial Coating for 2008 Cadillac CTS

PartNumber: 320.62140Product Specifications- Notes: 339mm Rear Disc; 345mm Front Disc; HD Brakes (J55)

- UPC: 889590392012

- Part Description: GCX Rotor With Partial Coating

OEM (Genuine) 2008 Cadillac CTS Rotor

PartNumber: 20808620 Product Specifications

Product Specifications- Notes: W/O AWD, W/O Heavy Duty; W/AWD, W/O Heavy Duty

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 15.6 x 15.2 x 3.5 inches

- Item Weight: 24.00 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15267102

- Part Description: Rotor

Centric® GCX Rotor With Partial Coating for 2008 Cadillac CTS

PartNumber: 320.62107Product Specifications- Notes: 339mm Rear Disc; 345mm Front Disc; HD Brakes (J55)

- UPC: 889590391824

- Part Description: GCX Rotor With Partial Coating

Centric® GCX Plain 1-Piece Rear Brake Rotor for 2008 Cadillac CTS

PartNumber: 320.62105Product Specifications- Notes: 315mm Front & Rear Disc; Std Brakes (JE5)

- UPC: 889590301878

- Part Description: GCX Plain 1-Piece Rear Brake Rotor

Bosch® QuietCast™ Premium Front Brake Rotor for 2008 Cadillac CTS

PartNumber: 25011428Product Specifications- Notes: 345mm rotor, HD brake

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 345mm (13.58")

- Rotor Style: Plain

- UPC: 077212085613

- Part Description: QuietCast™ Premium Front Brake Rotor

brembo® UV Coated Series Front Brake Rotor for 2008 Cadillac CTS

PartNumber: 09.D269.11Product Specifications- Notes: Exc.Heavy Duty Brakes

- Center Diameter: 67.5

- Coated: UV Coated

- Diameter (mm): 316

- Fixing Screws: included

- Height: 51.1

- Material: Grey Cast Iron

- Minimum Thickness (mm): 28.5

- Nominal Thickness (mm): 30

- Number of Holes: 5

- Quantity: 5

- Screw Material: Included

- Solid Or Vented Type Rotor: vented

- Part Description: UV Coated Series Front Brake Rotor

Bosch® QuietCast™ Premium Front Brake Rotor for 2008 Cadillac CTS

PartNumber: 25011429Product Specifications- Notes: 316mm rotor, std brake

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 316mm (12.44")

- Rotor Style: Plain

- UPC: 077212085637

- Part Description: QuietCast™ Premium Front Brake Rotor

brembo® UV Coated Series Rear Brake Rotor for 2008 Cadillac CTS

PartNumber: 09.D270.11Product Specifications- Notes: Heavy Duty Brakes; 18" Wheels

- Center Diameter: 67.5

- Coated: UV Coated

- Diameter (mm): 339

- Fixing Screws: included

- Height: 48.1

- Material: Grey Cast Iron

- Minimum Thickness (mm): 21.5

- Nominal Thickness (mm): 23

- Number of Holes: 5

- Quantity: 5

- Screw Material: Included

- Solid Or Vented Type Rotor: vented

- Part Description: UV Coated Series Rear Brake Rotor

Bosch® QuietCast™ Premium Rear Brake Rotor for 2008 Cadillac CTS

PartNumber: 25011431Product Specifications- Notes: 339mm rotor

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085668

- Part Description: QuietCast™ Premium Rear Brake Rotor

brembo® UV Coated Series Rear Brake Rotor for 2008 Cadillac CTS

PartNumber: 09.N286.11Product Specifications- Notes: Heavy Duty Brakes; 17" Wheels

- Coated: UV Coated

- Diameter (mm): 315

- Fixing Screws: included

- Height: 48

- Minimum Thickness (mm): 21

- Nominal Thickness (mm): 23

- Number of Holes: 5

- Quantity: 5

- Screw Material: Included

- Solid Or Vented Type Rotor: vented

- Part Description: UV Coated Series Rear Brake Rotor

FAQ for Brake Disc Repair

Q: What should you do if the lathe is equipped with a non-directional finishing tool?

A:

You should apply the finish with 120-grit aluminum oxide sandpaper.

By Bob

GM Specialist

01/11/2022Q: What special tools are needed in the process of brake rotor refinishing?

A:

You need to use the J 41013 Rotor Resurfacing Kit and the J 42450-A Wheel Hub Resurfacing Kit.

By Bob

GM Specialist

01/11/2022Q: What should you do if the lathe is not equipped with a non-directional finishing tool?

A:

You should apply the finish with a sanding block and 150-grit aluminum oxide sandpaper.

By Bob

GM Specialist

01/11/2022Q: What special tools are needed in the process of the rear brake rotor replacement?

A:

You need to use the J 41013 Rotor Resurfacing Kit and the J 42450-A Wheel Hub Resurfacing Kit.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the brake caliper bracket bolt?

A:

The recommended torque is 225Nm(166 lb-ft).

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the brake rotor screw?

A:

The recommended torque is 10Nm(89 lb in).

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the upper and lower brake caliper bracket bolt?

A:

The recommended torque is 130Nm(96 lb-ft).

By Bob

GM Specialist

01/11/2022Q: What special tools are needed in the process of the front brake rotor replacement?

A:

You need to use the J 41013 Rotor Resurfacing Kit and the J 42450-A Wheel Hub Resurfacing Kit.

By Bob

GM Specialist

01/11/2022See more FAQs (3)