< Back ×

My Vehicle Change Vehicle

2008 Cadillac CTS

< Back to View All

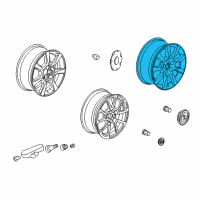

Wheels & Related Parts

- Department

- Prices

OEM (Genuine) 2008 Cadillac CTS Wheel

PartNumber: 9596616 Product Specifications

Product Specifications- Notes: 17x8, Code: Bkk

- Other Names: Wheel, Wheel Alloy

- Item Dimensions: 21.4 x 21.4 x 16.4 inches

- Item Weight: 22.80 Pounds

- Fitment Type: Direct Replacement

- Part Description: Wheel

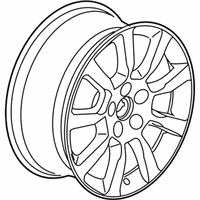

OEM (Genuine) 2008 Cadillac CTS Wheel

PartNumber: 9597875 Product Specifications

Product Specifications- Notes: 18x8.5, Code: Drp

- Other Names: Wheel

- Item Dimensions: 26.4 x 27.4 x 12.4 inches

- Item Weight: 28.30 Pounds

- Fitment Type: Direct Replacement

- Part Description: Wheel

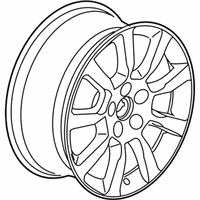

OEM (Genuine) 2008 Cadillac CTS Wheel

PartNumber: 9597874 Product Specifications

Product Specifications- Notes: 18x8.5, Code: Fsk

- Other Names: Wheel

- Item Dimensions: 27.7 x 26.4 x 12.6 inches

- Item Weight: 26.80 Pounds

- Fitment Type: Direct Replacement

- Part Description: Wheel

OEM (Genuine) 2008 Cadillac CTS Wheel-17X8.0 X48 Aluminum

PartNumber: 9596618 Product Specifications

Product Specifications- Notes: 17x8, Code: Jhn

- Other Names: Wheel, Wheel Alloy

- Item Dimensions: 21.6 x 21.6 x 13.7 inches

- Item Weight: 21.40 Pounds

- Fitment Type: Direct Replacement

- Part Description: Wheel-17X8.0 X48 Aluminum

FAQ for Alloy Wheels Repair

Q: How to repair the tire puncture generally?

A:

First, you need to remove the tire from the wheel for inspection and repair. Then, please fill the injury (puncture) to keep moisture out. Finally, you should seal the inner liner with a repair unit to prevent air loss.

By Bob

GM Specialist

01/11/2022Q: How to perform tire internal inspection?

A:

First, you need to spread the beads and mark the puncture with a tire crayon. Then, please inspect the inner tire for any signs of internal damage, remove the puncturing object, note the direction of the penetration, and probe the injury with a blunt awl to determine the extent and direction of the injury. Finally, you should remove any loose foreign material from the injury.

By Bob

GM Specialist

01/11/2022Q: What should be noticed about the Tire Rotation (Directional)?

A:

You need to rotate the tires and wheels at frequent intervals to equalize wear. Radial tires tend to wear faster in the shoulder area, particularly in front positions. Radial tires in non-drive locations may develop an irregular wear pattern that may increase tire noise. So. regular rotation is especially necessary. You should always use a 4-wheel rotation and check the wheel nuts for specified torque after rotation.

By Bob

GM Specialist

01/11/2022Q: What is the procedure for Tire Mounting and Dismounting?

A:

First, you need to deflate the tire completely. Then, please remove the tire from the wheel and remove any rubber, or corrosion from the wheel bead seats. You also need to apply GM P/N 12345884 (Canadian P/N 5728223) or equivalent to the tire bead and the wheel rim and use the tire changer to install the tire to the wheel. Finally, you should inflate the tire to the proper air pressure and ensure that the locating rings are visible on both sides of the tire to verify that the tire bead is fully seated on the wheel.

By Bob

GM Specialist

01/11/2022Q: What should be noticed about the Tire Rotation (Non-Directional)?

A:

You need to rotate the tires and wheels at frequent intervals to equalize wear. Radial tires tend to wear faster in the shoulder area, particularly in front positions. Radial tires in non-drive locations may develop an irregular wear pattern that may increase tire noise. So. regular rotation is especially necessary. You should always use a 4-wheel rotation and check the wheel nuts for specified torque after rotation.

By Bob

GM Specialist

01/11/2022Q: How to perform the Aluminum Wheel Porosity Repair?

A:

First, you need to remove the tire and wheel, inflate the tire to the manufactures specified pressure as stated on the tire, submerge the tire/wheel into a water bath to locate the leak, inscribe a mark on the wheel to indicate the leak areas and inscribe a mark on the tire at the valve stem to indicate the orientation of the tire to the wheel. Then, please remove the tire from the wheel, use number 80 grit sandpaper to scuff the inside of the rim surface at the leak area, and use general purpose cleaner such as 3M(R), P/N 08984 or equivalent, to clean the leak area. You also need to apply a 3 mm (0.12 in) thick layer of adhesive/sealant, GM US P/N 12378478 (Canada P/N 88900041) or equivalent, to the leak area, allow for the adhesive/sealant to dry, align the inscribed mark on the tire with the valve stem on the wheel and install the tire to the wheel. Finally, you should pressurize the tire to 276 kPa (40 psi), submerge the tire/wheel into a water bath to ensure the leak is sealed, inflate the tire to the specified pressure as stated on the tire placard, balance the tire and wheel and install the tire and wheel.

By Bob

GM Specialist

28/10/2022Q: How to refinish the Aluminum Wheel?

A:

First, you need to remove the tire and wheel assembly from the vehicle, remove the balance weights from the wheel and remove the tire from the wheel. Then, please use a suitable cleaner to remove the lubricants, wax, or dirt from the wheel, and remove the paint from the wheel. If the wheel had a machined aluminum finish, you can spin the wheel and restore the circular machined appearance. You also need to mask the wheel mounting surface and the wheel nut contact surface when following the paint manufacturer's instructions for painting the wheel. Finally, you should unmask the wheel, install a new valve stem, the tire to the wheel, and remove the corrosion, overspray, or dirt from the wheel mounting surface.

By Bob

GM Specialist

28/10/2022See more FAQs (2)