< Back ×

My Vehicle Change Vehicle

2008 Buick Enclave

< Back to View All

Brake Lines & Hoses

- Department

- Brands

- Prices

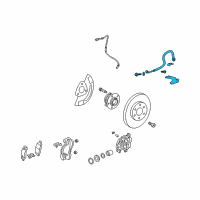

OEM (Genuine) 2008 Buick Enclave Brake Hose

PartNumber: 19366775 Product Specifications

Product Specifications- Location: Passenger Side

- Other Names: Brake Hose, Flex Hose

- Item Dimensions: 4.2 x 3.0 x 19.4 inches

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15115040

- Part Description: 2008 Buick Enclave Brake Hose

Vehicle Fitment- 2008 Buick Enclave | Base, Convenience, CX, CXL, Leather, Premium | 6 Cyl 3.6 L GAS

$35.19 MSRP:$66.42You Save: $31.23 (48%)

Centric® Front Passenger Side Brake Hose for 2008 Buick Enclave

PartNumber: 150.66133Product Specifications- UPC: 805890360544

- Part Description: 2008 Buick Enclave Front Passenger Side Brake Hose

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

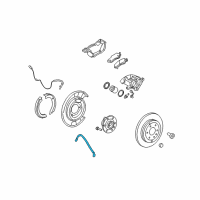

$11.74OEM (Genuine) 2008 Buick Enclave Brake Hose

PartNumber: 19366774 Product Specifications

Product Specifications- Location: Driver Side

- Other Names: Brake Hose, Flex Hose

- Item Dimensions: 4.2 x 3.1 x 19.4 inches

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15115039

- Part Description: 2008 Buick Enclave Brake Hose

Vehicle Fitment- 2008 Buick Enclave | Base, Convenience, CX, CXL, Leather, Premium | 6 Cyl 3.6 L GAS

$32.67 MSRP:$61.64You Save: $28.97 (47%)

Centric® Front Driver Side Brake Hose for 2008 Buick Enclave

PartNumber: 150.66134Product Specifications- UPC: 805890360575

- Part Description: 2008 Buick Enclave Front Driver Side Brake Hose

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

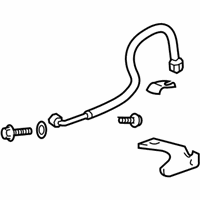

$11.74OEM (Genuine) 2008 Buick Enclave Brake Hose

PartNumber: 19368465 Product Specifications

Product Specifications- Notes: 2WD; AWD

- Location: Driver Side

- Other Names: Brake Hose, Flex Hose

- Item Dimensions: 3.1 x 3.2 x 16.5 inches

- Item Weight: 1.20 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25800751, 23494651, 15921567

- Part Description: 2008 Buick Enclave Brake Hose

Vehicle Fitment- 2008 Buick Enclave | Base, Convenience, CX, CXL, Leather, Premium | 6 Cyl 3.6 L GAS

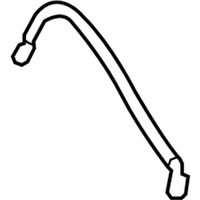

$28.53 MSRP:$53.85You Save: $25.32 (48%)OEM (Genuine) 2008 Buick Enclave Brake Hose

PartNumber: 19368466 Product Specifications

Product Specifications- Notes: 2WD; AWD

- Location: Passenger Side

- Other Names: Brake Hose, Flex Hose

- Item Dimensions: 8.6 x 12.4 x 0.5 inches

- Item Weight: 1.20 Pounds

- Fitment Type: Direct Replacement

- Replaces: 23494652, 25800749, 15921564

- Part Description: 2008 Buick Enclave Brake Hose

Vehicle Fitment- 2008 Buick Enclave | Base, Convenience, CX, CXL, Leather, Premium | 6 Cyl 3.6 L GAS

$28.53 MSRP:$53.85You Save: $25.32 (48%)

Centric® Rear Driver Side Brake Hose for 2008 Buick Enclave

PartNumber: 150.66376Product Specifications- UPC: 805890388654

- Part Description: 2008 Buick Enclave Rear Driver Side Brake Hose

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

$11.29

Centric® Rear Passenger Side Brake Hose for 2008 Buick Enclave

PartNumber: 150.66377Product Specifications- UPC: 805890388661

- Part Description: 2008 Buick Enclave Rear Passenger Side Brake Hose

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

$11.29

Wagner® Front Driver Side Brake Hydraulic Hose for 2008 Buick Enclave

PartNumber: BH143911Product Specifications- UPC: 008536669753

- Part Description: 2008 Buick Enclave Front Driver Side Brake Hydraulic Hose

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

Wagner® Rear Passenger Side Brake Hydraulic Hose for 2008 Buick Enclave

PartNumber: BH143910Product Specifications- UPC: 008536669746

- Part Description: 2008 Buick Enclave Rear Passenger Side Brake Hydraulic Hose

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

FAQ for Brake Hose Repair

Q: How do you install the rear brake hose?

A:

You can position the brake hose to the vehicle, install 2 new brake hose fitting gaskets, install the brake hose fitting bolt and the brake hose bracket bolt, connect the brake pipe fitting, bleed the hydraulic brake system, install the tire and wheel assembly, and then lower the vehicle.

By Bob

GM Specialist

01/11/2022Q: How many fittings does the brake pipe have?

A:

The brake pipe has a total of 2 fittings.

By Bob

GM Specialist

01/11/2022Q: What is the removal procedure for the rear brake hose?

A:

The procedure is to raise and support the vehicle, remove the tire and wheel assembly and any dirt or debris from the brake pipe fitting, disconnect the brake pipe fitting, and cap the brake pipe fitting to prevent brake fluid loss and contamination. And then remove the brake hose bracket bolt, the brake hose fitting bolt, the 2 brake hose fitting gaskets, and the brake hose.

By Bob

GM Specialist

01/11/2022Q: What is the replacement procedure for the brake pipe?

A:

The procedure is to inspect the area of brake pipe to be repaired or replaced, release the brake pipe to be replaced from the retainers as required, select an appropriate location to section the brake pipe if necessary, measure the length of the pipe to be replaced including all pipe bends, add to the measurement taken the appropriate additional length required for each flare to be created, cut the brake pipe squarely to the measured length, remove the sectioned brake pipe from the vehicle, select the appropriate size of brake pipe and tube nuts, as necessary, strip the nylon coating from the brake pipe end to be flared, if necessary, chamfer the inside and outside diameter of the pipe with the de-burring tool included in the J 45405, install the tube nuts on the brake pipe, clean the brake pipe and the J 45405 of lubricant, contaminants, and debris, loosen the die clamping screw of the J 45405, select the corresponding die set and install the die halves into the die cage with the full, flat face of one die facing the clamping screw, and the counterbores of both dies facing the forming ram, place the flat face of an unused die against the die halves in the clamping cage and hold firmly against the counterbored face of the dies, insert the prepared end of the pipe to be flared through the back of the dies until the pipe is seated against the flat surface of the unused die, remove the unused die, ensure that the rear of both dies are seated firmly against the enclosed end of the die cage, hand tighten the clamping screw against the dies, s20.elect the appropriate forming mandrel and place into the forming ram, rotate the hydraulic fluid control valve clockwise to the closed position and the body of the J 45405, operate the lever of the J 45405, rotate the hydraulic fluid control valve counterclockwise to the open position to allow the hydraulic forming ram to retract, insert the finishing cone into the forming ram, rotate the hydraulic fluid control valve clockwise to the closed position and the body of the J 45405, operate the lever of the J 45405, rotate the hydraulic fluid control valve counterclockwise to the open position to allow the hydraulic forming ram to retract, loosen the die clamping screw and remove the dies and pipe, lightly tap the dies until the die halves separate, inspect the brake pipe flare for correct shape and diameter (a), shape the new pipe with a suitable brake pipe bending tool, install the pipe to the vehicle with the appropriate brake pipe unions, as required, secure the brake pipe to the retainers, bleed the hydraulic brake system, and then inspect the brake pipe flares for leaks by starting the engine and applying the brakes.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the brake pipe fittings?

A:

The recommended torque is 20 Nm (15 lb-ft).

By Bob

GM Specialist

01/11/2022Q: How many gaskets does the Brake Hose Fitting have?

A:

The Brake Hose Fitting has a total of 2 gaskets.

By Bob

GM Specialist

29/10/2022Q: What is the recommended torque for the brake hose fitting bolts?

A:

The recommended torque is 40 Nm (30 lb-ft).

By Bob

GM Specialist

29/10/2022See more FAQs (2)