< Back ×

2008 Buick Enclave Brake Disc

My Vehicle Change Vehicle

2008 Buick Enclave

< Back to View All

Brake Pads, Discs & Calipers

- Department

- Brands

- Prices

$51.03Product Specifications

$51.03Product Specifications- UPC: 805890394440

- Part Description: 2008 Buick Enclave Premium Vented Front Brake Rotor

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

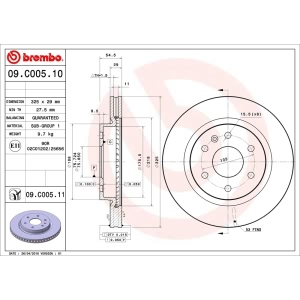

$73.96Product Specifications

$73.96Product Specifications- Bolt Circle: 132mm (5.2")

- Hub Hole Diameter: 75.6mm (2.98")

- Lug Holes Quantity: 6

- Lug Holes Size: 398.78mm (15.7")

- Minimum Thickness: 27.5mm (1.08")

- Nominal Thickness: 29mm (1.14")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 325mm (12.8")

- Rotor Height: 54.5mm (2.15")

- Rotor Style: Plain

- Part Description: 2008 Buick Enclave PowerStop Evolution Coated Rotor

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

$35.94Product Specifications

$35.94Product Specifications- Bolt Circle: 132mm (5.20")

- Center Hole Diameter: 75.6mm (2.98")

- Lug Holes Quantity: 6

- Lug Holes Size: 15.8mm (0.62")

- Minimum Thickness: 27.5mm (1.08")

- Nominal Thickness: 29mm (1.14")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 325mm (12.8")

- Rotor Height: 54.5mm (2.15")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632160680

- Part Description: 2008 Buick Enclave Vented Front Brake Rotor

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

$78.64Product Specifications

$78.64Product Specifications- Coated: UV Coated

- Diameter (mm): 325

- Height: 55

- Material: Grey Cast Iron

- Minimum Thickness (mm): 27.5

- Nominal Thickness (mm): 29

- Number of Holes: 6

- Quantity: 6

- Solid Or Vented Type Rotor: vented

- Part Description: 2008 Buick Enclave UV Coated Series Front Brake Rotor

Vehicle Fitment- 2008 Buick Enclave | CX | All Engines

- 2008 Buick Enclave | CXL | All Engines

$41.87Product Specifications

$41.87Product Specifications- UPC: 805890418139

- Part Description: 2008 Buick Enclave Premium Vented Rear Brake Rotor

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

OEM (Genuine) 2008 Buick Enclave Rotor

PartNumber: 22955495$72.34 MSRP:$136.49You Save: $64.15 (47%)Product Specifications- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 13.9 x 13.8 x 3.6 inches

- Item Weight: 23.20 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25853001, 10390111

- Part Description: 2008 Buick Enclave Rotor

Vehicle Fitment- 2008 Buick Enclave | Base, CX, CXL, Convenience, Leather, Premium | 6 Cyl 3.6 L GAS

$65.46Product Specifications

$65.46Product Specifications- Bolt Circle: 132mm (5.2")

- Hub Hole Diameter: 75.6mm (2.98")

- Lug Holes Quantity: 6

- Lug Holes Size: 411.48mm (16.2")

- Minimum Thickness: 18.4mm (0.72")

- Nominal Thickness: 20mm (0.79")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Drum-in-Hat

- Rotor Diameter: 331mm (13.03")

- Rotor Height: 53.4mm (2.1")

- Rotor Style: Plain

- Part Description: 2008 Buick Enclave PowerStop Evolution Coated Rotor

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

$32.46Product Specifications

$32.46Product Specifications- Bolt Circle: 132mm (5.20")

- Center Hole Diameter: 75.6mm (2.98")

- Lug Holes Quantity: 6

- Lug Holes Size: 16.1mm (0.63")

- Minimum Thickness: 18.4mm (0.72")

- Nominal Thickness: 20mm (0.79")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 331mm (13.03")

- Rotor Height: 53.4mm (2.1")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632161366

- Part Description: 2008 Buick Enclave Vented Rear Brake Rotor

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

$75.69Product Specifications

$75.69Product Specifications- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085316

- Part Description: 2008 Buick Enclave QuietCast™ Premium Front Brake Rotor

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

$67.24Product Specifications

$67.24Product Specifications- OE Part Number: 22768973

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085354

- Part Description: 2008 Buick Enclave QuietCast™ Premium Rear Brake Rotor

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

OEM (Genuine) 2008 Buick Enclave Rotor

PartNumber: 22768973$130.54 MSRP:$272.48You Save: $141.94 (53%)Product Specifications- Notes: 2WD; AWD

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 15.6 x 15.0 x 3.4 inches

- Item Weight: 19.40 Pounds

- Fitment Type: Direct Replacement

- Replaces: 10391043, 25858784

- Part Description: 2008 Buick Enclave Rotor

Vehicle Fitment- 2008 Buick Enclave | Base, CX, CXL, Convenience, Leather, Premium | 6 Cyl 3.6 L GAS

Product Specifications

Product Specifications- UPC: 889590253139

- Part Description: 2008 Buick Enclave GCX Plain 1-Piece Front Brake Rotor

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

Product Specifications

Product Specifications- UPC: 889590253146

- Part Description: 2008 Buick Enclave GCX Plain 1-Piece Rear Brake Rotor

Vehicle Fitment- 2008 Buick Enclave | All Trims | All Engines

FAQ for Brake Disc Repair

Q: What will need to be done before replacing the rear brake rotor?

A:

You will need to raise and support the vehicle and then remove the tire and wheel assembly.

By Bob

GM Specialist

01/11/2022Q: What is the refinishing procedure for the brake rotor?

A:

The procedure is to clean any rust or corrosion from the mating surface of the hub/axle flange and any rust or corrosion from the mating surface and mounting surface of the brake rotor, inspect the mating surfaces of the hub/axle flange and the rotor, mount the brake rotor to the brake lathe, slowly bring in the cutting tools until they just contact the brake rotor friction surfaces, observe the witness mark on the brake rotor, refinish the brake rotor, inspect the brake rotor thickness, follow the brake lathe manufacturer's recommended speed setting for applying a non-directional finish, apply the non-directional finish, clean each friction surface of the brake rotor with denatured alcohol, or an equivalent approved brake cleaner, remove the brake rotor from the brake lathe, and then measure the assembled LRO of the brake rotor to ensure optimum performance of the disc brakes.

By Bob

GM Specialist

01/11/2022Q: How many bolts does the brake caliper bracket have?

A:

The brake caliper bracket has a total of 2 bolts.

By Bob

GM Specialist

01/11/2022Q: What is the burnishing procedure for the brake pad and rotor?

A:

The procedure is to select a smooth road with little or no traffic, accelerate the vehicle to 48 km/h (30 mph), apply the brakes to bring the vehicle to a stop, and then repeat steps 2 and 3 until approximately 20 stops have been completed.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the brake caliper bracket bolts?

A:

The recommended torque is 175 Nm (129 lb-ft).

By Bob

GM Specialist

01/11/2022Q: What will need to be done before replacing the front brake rotor?

A:

You will need to raise and support the vehicle and then remove the tire and wheel assembly.

By Bob

GM Specialist

01/11/2022See more FAQs (1)