< Back ×

My Vehicle Change Vehicle

2007 Cadillac STS

< Back to View All

Brake Pads, Discs & Calipers

- Department

- Brands

- Prices

Centric® Premium Vented Rear Brake Rotor for 2007 Cadillac STS

PartNumber: 125.62076Product Specifications- Notes: 6 Lug; Brembo Brakes

- UPC: 805890730675

- Part Description: 2007 Cadillac STS Premium Vented Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$74.38OEM (Genuine) 2007 Cadillac STS Rotor

PartNumber: 25750248 Product Specifications

Product Specifications- Notes: Sts, W/O AWD, W/Performance Pkg, W/Heavy Duty; Sts, W/AWD, W/Heavy Duty; Sts-V

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 16.7 x 16.2 x 5.8 inches

- Item Weight: 26.40 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2007 Cadillac STS Rotor

Vehicle Fitment- 2007 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$129.30 MSRP:$235.09You Save: $105.79 (45%)

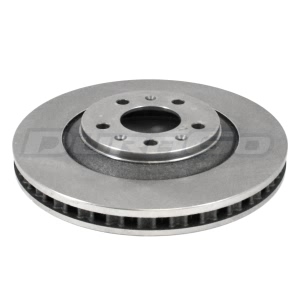

DuraGo® Vented Front Brake Rotor for 2007 Cadillac STS

PartNumber: BR900554Product Specifications- Notes: 6 Stud Whls

- Bolt Circle: 115mm (4.53")

- Center Hole Diameter: 70.8mm (2.79")

- Lug Holes Quantity: 6

- Lug Holes Size: 14.4mm (0.57")

- Minimum Thickness: 30mm (1.18")

- Nominal Thickness: 32mm (1.26")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 355mm (13.98")

- Rotor Height: 49.8mm (1.96")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632165104

- Part Description: 2007 Cadillac STS Vented Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$43.33

Power Stop® PowerStop Evolution Coated Rotor for 2007 Cadillac STS

PartNumber: AR82104EVCProduct Specifications- Notes: Std Brakes (JL9)

- Bolt Circle: 115mm (4.53")

- Hub Hole Diameter: 70.7mm (2.78")

- Lug Holes Quantity: 5

- Lug Holes Size: 330.2mm (13")

- Minimum Thickness: 24mm (0.94")

- Nominal Thickness: 26mm (1.02")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 298mm (11.73")

- Rotor Height: 48.2mm (1.9")

- Rotor Style: Plain

- Part Description: 2007 Cadillac STS PowerStop Evolution Coated Rotor

Vehicle Fitment- 2007 Cadillac STS | Base | All Engines

$47.31

Centric® Premium Vented Front Brake Rotor for 2007 Cadillac STS

PartNumber: 125.62084Product Specifications- Notes: 323mm Front Disc; 5 Lug; Perf Brakes

- UPC: 805890730705

- Part Description: 2007 Cadillac STS Premium Vented Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$57.46

Bosch® QuietCast™ Premium Vented Front Brake Rotor for 2007 Cadillac STS

PartNumber: 25010615Product Specifications- Notes: 303mm rotor, std brake system

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 303mm (11.93")

- Rotor Style: Plain

- UPC: 077212084258

- Part Description: 2007 Cadillac STS QuietCast™ Premium Vented Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$45.73OEM (Genuine) 2007 Cadillac STS Rotor

PartNumber: 25750257 Product Specifications

Product Specifications- Notes: W/Performance Pkg, W/Heavy Duty

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 17.0 x 16.0 x 4.0 inches

- Item Weight: 23.40 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2007 Cadillac STS Rotor

Vehicle Fitment- 2007 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$76.87 MSRP:$217.92You Save: $141.05 (65%)

DuraGo® Vented Front Brake Rotor for 2007 Cadillac STS

PartNumber: BR55105Product Specifications- Notes: 5 Stud Whls; 12.72" Rotor Dia

- Bolt Circle: 115mm (4.53")

- Center Hole Diameter: 70.7mm (2.78")

- Lug Holes Quantity: 5

- Lug Holes Size: 14.3mm (0.56")

- Minimum Thickness: 30.7mm (1.21")

- Nominal Thickness: 32.2mm (1.27")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 323mm (12.72")

- Rotor Height: 51.9mm (2.04")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632149074

- Part Description: 2007 Cadillac STS Vented Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$46.39

Centric® Premium Vented Rear Brake Rotor for 2007 Cadillac STS

PartNumber: 125.62088Product Specifications- Notes: 323mm Front Disc; 5 Lug; Perf Brakes

- UPC: 805890730712

- Part Description: 2007 Cadillac STS Premium Vented Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$65.09OEM (Genuine) 2007 Cadillac STS Rotor

PartNumber: 15240719 Product Specifications

Product Specifications- Notes: W/O Performance Pkg

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 15.3 x 15.1 x 3.8 inches

- Item Weight: 16.00 Pounds

- Fitment Type: Direct Replacement

- Replaces: 25693146

- Part Description: 2007 Cadillac STS Rotor

Vehicle Fitment- 2007 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$89.90 MSRP:$169.63You Save: $79.73 (48%)

DuraGo® Vented Front Brake Rotor for 2007 Cadillac STS

PartNumber: BR55096Product Specifications- Notes: 5 Stud Whls; 11.93" Rotor Dia

- Bolt Circle: 115mm (4.53")

- Center Hole Diameter: 70.7mm (2.78")

- Lug Holes Quantity: 5

- Lug Holes Size: 14.3mm (0.56")

- Minimum Thickness: 30.7mm (1.21")

- Nominal Thickness: 32.3mm (1.27")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 303mm (11.93")

- Rotor Height: 51.6mm (2.03")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632132502

- Part Description: 2007 Cadillac STS Vented Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$43.93OEM (Genuine) 2007 Cadillac STS Rear Brake Rotor

PartNumber: 25846216 Product Specifications

Product Specifications- Notes: W/Performance Pkg, W/O Heavy Duty

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 15.3 x 14.4 x 3.3 inches

- Item Weight: 19.60 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15235140, 25737788

- Part Description: 2007 Cadillac STS Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

$52.98 MSRP:$165.96You Save: $112.98 (69%)

DuraGo® Vented Rear Brake Rotor for 2007 Cadillac STS

PartNumber: BR900830Product Specifications- Notes: 6 Stud Whls

- Bolt Circle: 115mm (4.53")

- Center Hole Diameter: 70.8mm (2.79")

- Lug Holes Quantity: 6

- Lug Holes Size: 14.2mm (0.56")

- Minimum Thickness: 26mm (1.02")

- Nominal Thickness: 28mm (1.1")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 365mm (14.37")

- Rotor Height: 45.1mm (1.78")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632173031

- Part Description: 2007 Cadillac STS Vented Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$40.65

Centric® Premium Vented Front Brake Rotor for 2007 Cadillac STS

PartNumber: 125.62070Product Specifications- Notes: 303mm Front Disc; 5 Lug; Standard Brakes

- UPC: 805890730644

- Part Description: 2007 Cadillac STS Premium Vented Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$63.12

DuraGo® Vented Rear Brake Rotor for 2007 Cadillac STS

PartNumber: BR900372Product Specifications- Notes: 5 Stud Whls; 12.6" Rotor Dia

- Bolt Circle: 115mm (4.53")

- Center Hole Diameter: 70.7mm (2.78")

- Lug Holes Quantity: 5

- Lug Holes Size: 13.2mm (0.52")

- Minimum Thickness: 24mm (0.94")

- Nominal Thickness: 26mm (1.02")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 320mm (12.6")

- Rotor Height: 48.2mm (1.90")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632161335

- Part Description: 2007 Cadillac STS Vented Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$37.57

DuraGo® Vented Rear Brake Rotor for 2007 Cadillac STS

PartNumber: BR55098Product Specifications- Notes: 5 Stud Whls; 11.73" Rotor Dia

- Bolt Circle: 115mm (4.53")

- Center Hole Diameter: 70.8mm (2.79")

- Lug Holes Quantity: 5

- Lug Holes Size: 13mm (0.51")

- Minimum Thickness: 24mm (0.94")

- Nominal Thickness: 26mm (1.02")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 298mm (11.73")

- Rotor Height: 48.1mm (1.89")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632155181

- Part Description: 2007 Cadillac STS Vented Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$31.42

Centric® Premium Vented Rear Brake Rotor for 2007 Cadillac STS

PartNumber: 125.62071Product Specifications- Notes: 303mm Front Disc; 5 Lug; Standard Brakes

- UPC: 805890730651

- Part Description: 2007 Cadillac STS Premium Vented Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$49.45

Centric® GCX Plain 1-Piece Rear Brake Rotor for 2007 Cadillac STS

PartNumber: 320.62071Product Specifications- Notes: 303mm Front Disc; 5 Lug; Standard Brakes

- UPC: 889590301823

- Part Description: 2007 Cadillac STS GCX Plain 1-Piece Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$36.49

Centric® Premium Vented Front Brake Rotor for 2007 Cadillac STS

PartNumber: 125.62075Product Specifications- Notes: 6 Lug; Brembo Brakes

- UPC: 805890730668

- Part Description: 2007 Cadillac STS Premium Vented Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

$76.38OEM (Genuine) 2007 Cadillac STS Rotor

PartNumber: 88964102 Product Specifications

Product Specifications- Notes: Sts, W/O AWD, W/O Performance Pkg; Sts, Sts-V; W/O Heavy Duty; W/4 Wheel Anti-Lock

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 15.4 x 14.7 x 3.5 inches

- Item Weight: 24.20 Pounds

- Fitment Type: Direct Replacement

- Replaces: 18060686

- Part Description: 2007 Cadillac STS Rotor

Vehicle Fitment- 2007 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

Bosch® QuietCast™ Premium Rear Brake Rotor for 2007 Cadillac STS

PartNumber: 25010707Product Specifications- Notes: JE5 perf brakes;JE5 perf brakes;

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085415

- Part Description: 2007 Cadillac STS QuietCast™ Premium Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | 6 Cyl 3.6L

- 2007 Cadillac STS | All Trims | 8 Cyl 4.4L

Centric® GCX Plain 1-Piece Front Brake Rotor for 2007 Cadillac STS

PartNumber: 320.62084CProduct Specifications- Notes: 323mm Front Disc; 5 Lug; Perf Brakes

- UPC: 889590406580

- Part Description: 2007 Cadillac STS GCX Plain 1-Piece Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

Centric® GCX Plain 1-Piece Front Brake Rotor for 2007 Cadillac STS

PartNumber: 320.62070CProduct Specifications- Notes: 303mm Front Disc; 5 Lug; Standard Brakes

- UPC: 889590415469

- Part Description: 2007 Cadillac STS GCX Plain 1-Piece Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

Bosch® QuietCast™ Premium Front Brake Rotor for 2007 Cadillac STS

PartNumber: 25011445Product Specifications- Notes: Ride & Handling pkg

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085866

- Part Description: 2007 Cadillac STS QuietCast™ Premium Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

Bosch® QuietCast™ Premium Rear Brake Rotor for 2007 Cadillac STS

PartNumber: 25011446Product Specifications- Notes: JL9 std brake system

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085880

- Part Description: 2007 Cadillac STS QuietCast™ Premium Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | 8 Cyl 4.6L

Bosch® QuietCast™ Premium Rear Brake Rotor for 2007 Cadillac STS

PartNumber: 25011447Product Specifications- Notes: V SERIES

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085897

- Part Description: 2007 Cadillac STS QuietCast™ Premium Rear Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | 8 Cyl 4.6L

OEM (Genuine) 2007 Cadillac STS Rotor

PartNumber: 19303811 Product Specifications

Product Specifications- Notes: Sts, W/O AWD, W/Performance Pkg, W/O Heavy Duty; Sts, W/AWD, W/O Heavy Duty; Sts, Sts-V; W/O Heavy Duty; W/O 4 Wheel Anti-Lock

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 15.9 x 15.9 x 5.8 inches

- Item Weight: 17.10 Pounds

- Fitment Type: Direct Replacement

- Replaces: 89047762

- Part Description: 2007 Cadillac STS Rotor

Vehicle Fitment- 2007 Cadillac STS | Base, Platinum, V | 6 Cyl 3.6 L GAS, 8 Cyl 4.4 L GAS, 8 Cyl 4.6 L GAS

Bosch® QuietCast™ Premium Front Brake Rotor for 2007 Cadillac STS

PartNumber: 25011448Product Specifications- Notes: Brembo caliper

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212085910

- Part Description: 2007 Cadillac STS QuietCast™ Premium Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

Bosch® QuietCast™ Premium Front Brake Rotor for 2007 Cadillac STS

PartNumber: 25011451Product Specifications- Notes: 316mm rotor (12.44")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 316mm (12.44")

- Rotor Style: Plain

- UPC: 077212085941

- Part Description: 2007 Cadillac STS QuietCast™ Premium Front Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

Centric® Gcx Brake Rotor for 2007 Cadillac STS

PartNumber: 320.62070HProduct Specifications- Notes: 303mm Front Disc; 5 Lug; Standard Brakes

- UPC: 889590391657

- Part Description: 2007 Cadillac STS Gcx Brake Rotor

Vehicle Fitment- 2007 Cadillac STS | All Trims | All Engines

1-30 of 34 Results

< Previous

12

Next >FAQ for Brake Disc Repair

Q: What should you check for before refinishing a brake rotor?

A:

Before that, the rotor MUST first be checked for adequate thickness to allow the rotor to be refinished and remain above the minimum allowable thickness after refinishing specification.

By Bob

GM Specialist

01/11/2022Q: What should you notice when removing the brake rotor?

A:

Do not force the rotor off. If the rotor is difficult to remove, ease it off by gently rotating it as you pull outward.

By Bob

GM Specialist

01/11/2022Q: Which lathe is essential for performing brake work, the bench or the on-car?

A:

Dealers must have a well-maintained bench lathe and a well-maintained on-car lathe. These lathes need to be calibrated monthly. BOTH lathes are essential to providing quality brake service.

By Bob

GM Specialist

01/11/2022Q: What kind of special tools will be used when refinishing the Brake Rotor?

A:

J41013 Rotor Resurfacing Kit, J 42450-A Wheel Hub Resurfacing Kit.

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the brake rotor mounting screw?

A:

The recommended torque is 14 N.m (124 lb in).

By Bob

GM Specialist

01/11/2022Q: Is it okay to leave the caliper/pads installed while cutting rotors using an on-car lathe?

A:

On-car lathes should never be used with the pads and calipers installed on the vehicle. The debris from cutting the rotors can contaminate the brake pads/calipers which can lead to other brake concerns and comebacks.

By Bob

GM Specialist

01/11/2022Q: What should you know when road-testing a vehicle?

A:

You can road test a vehicle under safe conditions while obeying all traffic laws. Do not attempt any maneuvers that could jeopardize vehicle control.

By Bob

GM Specialist

01/11/2022Q: What should you notice when removing the tire and wheel assembly?

A:

Do NOT disconnect the hydraulic brake flexible hose from the caliper.

By Bob

GM Specialist

01/11/2022See more FAQs (3)