< Back ×

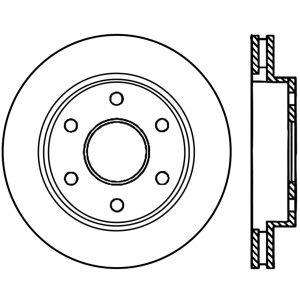

2004 Cadillac Escalade EXT Brake Disc

My Vehicle Change Vehicle

2004 Cadillac Escalade EXT

< Back to View All

Brake Pads, Discs & Calipers

- Department

- Brands

- Prices

$56.19Product Specifications

$56.19Product Specifications- UPC: 805890068983

- Part Description: Premium Vented Rear Brake Rotor

Power Stop® PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair for 2004 Cadillac Escalade EXT

PartNumber: AR8645XPR$249.71Product Specifications- Bolt Circle: 140mm (5.5")

- Driving Style: Performance / Racing

- Drum-in-Hat Inside Diameter: 210.27mm (8.28")

- Hub Hole Diameter: 78.71mm (3.1")

- Lug Holes Quantity: 6

- Lug Holes Size: 16.51mm (0.65")

- Minimum Thickness: 28.5mm (1.12")

- Nominal Thickness: 30.05mm (1.18")

- Quantity: 2 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (13")

- Rotor Finish: Zinc Coated

- Rotor Height: 95.59mm (3.76")

- Rotor Material: Cast Iron

- Rotor Style: Drilled & Slotted

- Rotor Type: Vented

- Part Description: PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair

$36.66Product Specifications

$36.66Product Specifications- Bolt Circle: 139.7mm (5.5")

- Center Hole Diameter: 78.6mm (3.09")

- Lug Holes Quantity: 6

- Lug Holes Size: 16.6mm (0.65")

- Minimum Thickness: 28.5mm (1.12")

- Nominal Thickness: 30.1mm (1.19")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Height: 95.5mm (3.76")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632117196

- Part Description: Vented Rear Brake Rotor

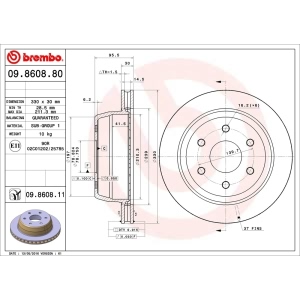

brembo® UV Coated Series Vented Rear Brake Rotor for 2004 Cadillac Escalade EXT

PartNumber: 09.8608.81$72.79Product Specifications- Coated: UV Coated

- Diameter (mm): 330

- Height: 96

- Material: Grey Cast Iron

- Minimum Thickness (mm): 28.5

- Nominal Thickness (mm): 30

- Number of Holes: 6

- Quantity: 6

- Solid Or Vented Type Rotor: vented

- Part Description: UV Coated Series Vented Rear Brake Rotor

$88.06Product Specifications

$88.06Product Specifications- UPC: 805890133315

- Part Description: Premium Vented Rear Brake Rotor

- $96.96 MSRP:

$182.96You Save: $86.00 (48%)Product Specifications- Notes: 4WD, 1500

- Location: Driver Side; Passenger Side

- Other Names: Rotor

- Item Dimensions: 13.6 x 12.8 x 3.7 inches

- Item Weight: 20.00 Pounds

- Fitment Type: Direct Replacement

- Replaces: 18060214

- Part Description: Rotor

Power Stop® PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair for 2004 Cadillac Escalade EXT

PartNumber: AR8640XPR$211.45Product Specifications- Bolt Circle: 140mm (5.5")

- Driving Style: Performance / Racing

- Hub Hole Diameter: 78.38mm (3.09")

- Lug Holes Quantity: 6

- Lug Holes Size: 16mm (0.63")

- Minimum Thickness: 27.2mm (1.07")

- Nominal Thickness: 28.9mm (1.14")

- Quantity: 2 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 305mm (12.01")

- Rotor Finish: Zinc Coated

- Rotor Height: 58.16mm (2.29")

- Rotor Material: Cast Iron

- Rotor Style: Drilled & Slotted

- Rotor Type: Vented

- Part Description: PowerStop Evolution Performance Drilled, Slotted& Plated Brake Rotor Pair

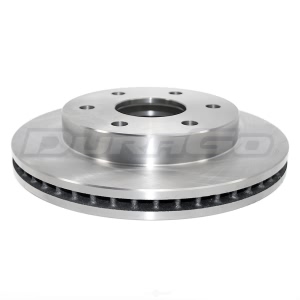

$32.84Product Specifications

$32.84Product Specifications- Bolt Circle: 139.7mm (5.5")

- Center Hole Diameter: 78.6mm (3.09")

- Lug Holes Quantity: 6

- Lug Holes Size: 16.5mm (0.65")

- Minimum Thickness: 27.2mm (1.07")

- Nominal Thickness: 29mm (1.14")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 304.5mm (11.99")

- Rotor Height: 58mm (2.28")

- Rotor Style: Plain

- Rotor Vane Type: Non-Directional

- UPC: 756632117158

- Part Description: Vented Front Brake Rotor

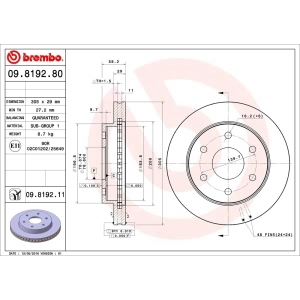

$65.81Product Specifications

$65.81Product Specifications- Coated: UV Coated

- Diameter (mm): 305

- Height: 58

- Material: Grey Cast Iron

- Minimum Thickness (mm): 27.2

- Nominal Thickness (mm): 29

- Number of Holes: 6

- Quantity: 6

- Solid Or Vented Type Rotor: vented

- Part Description: UV Coated Series Front Brake Rotor

$45.06Product Specifications

$45.06Product Specifications- UPC: 805890036241

- Part Description: Premium Vented Front Brake Rotor

$78.75Product Specifications

$78.75Product Specifications- Bolt Circle: 139.7mm (5.5")

- Drum-in-Hat Inside Diameter: 210.27mm (8.28")

- Hub Hole Diameter: 78.71mm (3.1")

- Lug Holes Quantity: 6

- Lug Holes Size: 16.51mm (0.65")

- Minimum Thickness: 28.5mm (1.12")

- Nominal Thickness: 30.05mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Drum-in-Hat

- Rotor Diameter: 330mm (12.99")

- Rotor Height: 95.59mm (3.76")

- Rotor Style: Plain

- Part Description: PowerStop Evolution Coated Rotor

- $118.23 MSRP:

$219.81You Save: $101.58 (47%)Product Specifications- Notes: 1500

- Location: Driver Side; Passenger Side

- Other Names: Brake Rotor, Rotor

- Item Dimensions: 16.0 x 15.9 x 5.7 inches

- Item Weight: 19.20 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15065077, 15712802

- Part Description: Rotor

$65.70Product Specifications

$65.70Product Specifications- Bolt Circle: 139.7mm (5.5")

- Hub Hole Diameter: 78.38mm (3.09")

- Lug Holes Quantity: 6

- Lug Holes Size: 16mm (0.63")

- Minimum Thickness: 27.2mm (1.07")

- Nominal Thickness: 28.9mm (1.14")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 305mm (12.01")

- Rotor Height: 58.16mm (2.29")

- Rotor Style: Plain

- Part Description: PowerStop Evolution Coated Rotor

Bosch® QuietCast™ Premium Vented Rear Brake Rotor for 2004 Cadillac Escalade EXT

PartNumber: 25010546$71.57Product Specifications- Notes: 330mm Dia;

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212082803

- Part Description: QuietCast™ Premium Vented Rear Brake Rotor

Bosch® QuietCast™ Premium Vented Front Brake Rotor for 2004 Cadillac Escalade EXT

PartNumber: 25010534$64.59Product Specifications- Lug Holes Quantity: 6

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Style: Plain

- UPC: 077212082605

- Part Description: QuietCast™ Premium Vented Front Brake Rotor

Product Specifications

Product Specifications- UPC: 889590253009

- Part Description: GCX Rotor With Partial Coating

Product Specifications

Product Specifications- UPC: 889590252958

- Part Description: GCX Plain 1-Piece Front Brake Rotor

Product Specifications

Product Specifications- Notes: with Black E-Coat on non-braking surface to prevent rust and corrosion;6 Stud Wheel;with 330mm Diameter Rotor

- Bolt Circle: 139.45mm (5.49")

- Lug Holes Quantity: 6

- Minimum Thickness: 28.5mm (1.122")

- Nominal Thickness: 29.97mm (1.18")

- Quantity: 1 Per Pack

- Rotor Construction: 1-Piece

- Rotor Design: Rotors Only

- Rotor Diameter: 330mm (12.99")

- Rotor Finish: With E-Shield™ Coating

- Rotor Height: 95.758mm (3.77")

- Rotor Material: Cast Iron

- Rotor Style: Plain

- UPC: 008536942016

- Part Description: Vented Rear Brake Rotor

Product Specifications

Product Specifications- UPC: 805890133261

- Part Description: Premium™ Brake Rotor

FAQ for Brake Disc Repair

Q: What should we do to obtain the desired non-directional finish after refinishing the brake rotor?

A:

You should follow the brake lathe manufacturer's recommended speed setting for applying a non-directional finish, apply the non-directional finish using moderate pressure, and clean each friction surface of the brake rotor with denatured alcohol, or an equivalent approved brake cleaner after applying a non-directional finish.

By Bob

GM Specialist

01/11/2022Q: What is the removal procedure for the front disc brake splash shield?

A:

You need to raise and support the vehicle, remove the tire and wheel assembly, the hub and bearing assembly, the splash shield (15 series), and the splash shield (25 series).

By Bob

GM Specialist

01/11/2022Q: What should we do when the brake rotor has been separated from the hub/axle flange?

A:

Whenever the brake rotor has been separated from the hub/axle flange, you should clean any rust or contaminants from the hub/axle flange and the brake rotor mating surfaces.

By Bob

GM Specialist

01/11/2022Q: What is the installation procedure for the front disc brake splash shield?

A:

You need to install the splash shield (25 Series), the splash shield (15 series), the hub and bearing assembly, and the tire and wheel assembly, remove the safety stands and lower the vehicle.

By Bob

GM Specialist

01/11/2022Q: What should we do if the rotor is difficult to remove due to corrosion in the hub area?

A:

If the rotor is difficult to remove due to corrosion in the hub area, you should clean all the surface areas and the threaded holes of contamination, apply penetrating oil or the equivalent to the hub/rotor area, insert M10 x 1.5 bolts into the threaded holes of the rotor, and tighten both bolts evenly to force the rotor from the hub.

By Bob

GM Specialist

01/11/2022Q: What should be noticed when removing the brake rotor of the front?

A:

Any new rotor must have the protective coating removed from the friction surfaces before being placed in service. Remove the protective coating using denatured alcohol or an equivalent, and wipe the surface clean with clean cloths. Do not use gasoline, kerosene, or other oil base solvents which may leave an oily residue. This residue is damaging to the brake lining and is flammable.

By Bob

GM Specialist

01/11/2022Q: How do on-car lathes react to Axle Float? Does the play affect the machining of the rotor, either surface finish or LRO?

A:

Because the Pro-Cut on-car lathe adjusts in a live mode while spinning the hub/rotor, the dynamics of a floating axle are effectively eliminated. Once the lathe is compensated, there is no difference in the cutting/surface finish and LRO are just the same as with a non-floating axle.

By Bob

GM Specialist

01/11/2022Q: What is the recommended bolt torque for the backing plate nuts?

A:

The recommended bolt torque is 135 Nm (100 ft. lbs.).

By Bob

GM Specialist

01/11/2022Q: What is the removal procedure for the disc brake backing plate of the rear (W/O NYS)?

A:

You need to release the parking brake, raise and support the vehicle, remove the tire and wheel assembly, relieve the tension from the park brake cable, and remove the park brake cable from the mounting bracket, and the rear park brake cable end from the park brake actuator lever and the rotor. You also need to remove the axle shaft, the park brake shoe, the backing plate nuts, and the backing plate from the axle housing flange.

By Bob

GM Specialist

01/11/2022Q: What should we do when the disc brake rotors have been refinished or replaced, and/or the disc brake pads have been replaced?

A:

You should select a smooth road with little or no traffic, accelerate the vehicle to 48 km/h (30 mph), apply the brakes to bring the vehicle to a stop using moderate to firm pressure, and do not allow the brakes to lock. Then you should repeat the two steps until approximately 20 stops have been completed, and allow sufficient cooling periods between stops to properly burnish the brake pads and rotors.

By Bob

GM Specialist

01/11/2022See more FAQs (7)