< Back ×

My Vehicle Change Vehicle

2000 GMC C3500

< Back to View All

Driveline, Axles & 4WD

- Department

- Prices

OEM (Genuine) 2000 GMC C3500 Outer Shaft

PartNumber: 26059714 Product Specifications

Product Specifications- Notes: 4WD, 3500

- Location: Driver Side

- Other Names: Outer Shaft, Output Shaft

- Item Dimensions: 7.5 x 6.9 x 6.9 inches

- Item Weight: 6.90 Pounds

- Replaced by: 26058806

- Part Description: 2000 GMC C3500 Outer Shaft

Vehicle Fitment- 2000 GMC C3500 | Sierra SL, Sierra SLE, Sierra SLT | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

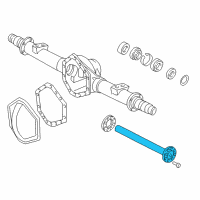

$683.33 MSRP:$883.44You Save: $200.11 (23%)OEM (Genuine) 2000 GMC C3500 Axle Shafts

PartNumber: 26010416 Product Specifications

Product Specifications- Notes: All Models; 2WD

- Other Names: Axle Shaft

- Item Dimensions: 32.4 x 6.6 x 6.7 inches

- Item Weight: 19.30 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2000 GMC C3500 Axle Shafts

Vehicle Fitment- 2000 GMC C3500 | Sierra, Sierra SL, Sierra SLE, Sierra SLT, Sierra SLX | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.2 L DIESEL, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

$239.61 MSRP:$380.44You Save: $140.83 (38%)OEM (Genuine) 2000 GMC C3500 Inner Shaft

PartNumber: 19121909 Product Specifications

Product Specifications- Notes: 4WD, Axle Clutch, All

- Other Names: Inner Shaft, Pinion Shaft, Shaft

- Item Dimensions: 8.8 x 3.9 x 3.5 inches

- Item Weight: 3.10 Pounds

- Fitment Type: Direct Replacement

- Replaces: 15521907

- Part Description: 2000 GMC C3500 Inner Shaft

Vehicle Fitment- 2000 GMC C3500 | Sierra, Sierra SL, Sierra SLE, Sierra SLT, Sierra SLX | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.2 L DIESEL, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

$213.29 MSRP:$353.04You Save: $139.75 (40%)OEM (Genuine) 2000 GMC C3500 Axle Shaft

PartNumber: 3977383 Product Specifications

Product Specifications- Notes: All Models; Left Side

- Item Dimensions: 33.6 x 4.4 x 4.3 inches

- Item Weight: 15.50 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2000 GMC C3500 Axle Shaft

Vehicle Fitment- 2000 GMC C3500 | Base, High Sierra, Sierra, Sierra Classic, Sierra SL, Sierra SLE, Sierra SLT, Sierra SLX | 6 Cyl 4.8 L GAS, 8 Cyl 5.0 L GAS, 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.2 L DIESEL, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

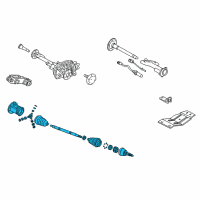

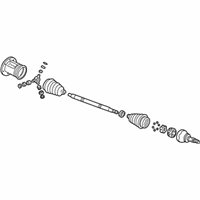

OEM (Genuine) 2000 GMC C3500 Front Wheel Drive Shaft Kit

PartNumber: 26062614 Product Specifications

Product Specifications- Notes: 4WD, All

- Location: Driver Side; Passenger Side

- Other Names: Axle Assembly

- Item Dimensions: 27.0 x 6.9 x 7.7 inches

- Item Weight: 28.10 Pounds

- Fitment Type: Direct Replacement

- Replaces: 26055393, 26037363, 26020727

- Part Description: 2000 GMC C3500 Front Wheel Drive Shaft Kit

Vehicle Fitment- 2000 GMC C3500 | Sierra, Sierra SL, Sierra SLE, Sierra SLT, Sierra SLX | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.2 L DIESEL, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

OEM (Genuine) 2000 GMC C3500 Rear Axle Drive Shaft

PartNumber: 26011162 Product Specifications

Product Specifications- Notes: 1995-00, 3/4 & 1 Ton W/10.5" Ring Gear, W/Dual Wheels

- Location: Passenger Side

- Other Names: Axle Shaft

- Item Dimensions: 43.3 x 4.7 x 4.6 inches

- Item Weight: 19.20 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2000 GMC C3500 Rear Axle Drive Shaft

Vehicle Fitment- 2000 GMC C3500 | Sierra, Sierra SL, Sierra SLE, Sierra SLT, Sierra SLX | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.2 L DIESEL, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

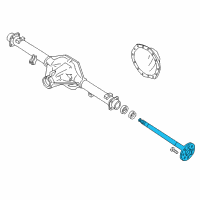

OEM (Genuine) 2000 GMC C3500 Axle Shaft

PartNumber: 15522068 Product Specifications

Product Specifications- Notes: 1995-00, 3/4 & 1 Ton W/9.5" Ring Gear, 2WD; All Models; All; 2WD

- Location: Driver Side; Passenger Side

- Item Dimensions: 33.8 x 8.4 x 8.2 inches

- Item Weight: 23.90 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2000 GMC C3500 Axle Shaft

Vehicle Fitment- 2000 GMC C3500 | Sierra, Sierra SL, Sierra SLE, Sierra SLT, Sierra SLX | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.2 L DIESEL, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

OEM (Genuine) 2000 GMC C3500 Shaft, Rear Axle

PartNumber: 26020040 Product Specifications

Product Specifications- Notes: 1995-00, 3/4 & 1 Ton W/10.5" Ring Gear, W/O Dual Wheels; All Models; Right

- Location: Passenger Side

- Other Names: Axle Shaft

- Item Dimensions: 37.6 x 4.7 x 4.5 inches

- Item Weight: 18.40 Pounds

- Part Description: 2000 GMC C3500 Shaft, Rear Axle

Vehicle Fitment- 2000 GMC C3500 | Sierra, Sierra SL, Sierra SLE, Sierra SLT, Sierra SLX | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.2 L DIESEL, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

OEM (Genuine) 2000 GMC C3500 Shaft, Rear Axle

PartNumber: 26020039 Product Specifications

Product Specifications- Notes: 1995-00, 3/4 & 1 Ton W/10.5" Ring Gear, W/O Dual Wheels

- Location: Driver Side

- Other Names: Axle Shaft

- Item Dimensions: 34.0 x 4.6 x 4.5 inches

- Item Weight: 17.10 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2000 GMC C3500 Shaft, Rear Axle

Vehicle Fitment- 2000 GMC C3500 | Sierra, Sierra SL, Sierra SLE, Sierra SLT, Sierra SLX | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.2 L DIESEL, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

OEM (Genuine) 2000 GMC C3500 Rear Axle Drive Shaft

PartNumber: 26011161 Product Specifications

Product Specifications- Notes: 1995-00, 3/4 & 1 Ton W/10.5" Ring Gear, W/Dual Wheels

- Location: Driver Side

- Other Names: Axle Shaft

- Item Dimensions: 39.9 x 4.7 x 4.6 inches

- Item Weight: 19.30 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2000 GMC C3500 Rear Axle Drive Shaft

Vehicle Fitment- 2000 GMC C3500 | Sierra, Sierra SL, Sierra SLE, Sierra SLT, Sierra SLX | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.2 L DIESEL, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

OEM (Genuine) 2000 GMC C3500 Rear Axle Drive Shaft

PartNumber: 15521928 Product Specifications

Product Specifications- Notes: 1995-00, 3/4 & 1 Ton W/9.5" Ring Gear, 4WD

- Location: Driver Side; Passenger Side

- Other Names: Axle Shaft

- Item Dimensions: 35.9 x 8.2 x 8.2 inches

- Item Weight: 26.70 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2000 GMC C3500 Rear Axle Drive Shaft

Vehicle Fitment- 2000 GMC C3500 | Sierra, Sierra SL, Sierra SLE, Sierra SLT, Sierra SLX | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.2 L DIESEL, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

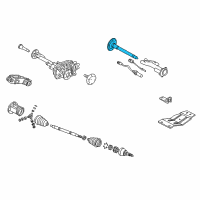

OEM (Genuine) 2000 GMC C3500 Front Drive Axle Inner Shaft

PartNumber: 26059716 Product Specifications

Product Specifications- Notes: 4WD, 3500

- Location: Passenger Side

- Other Names: Inner Shaft, Outer Shaft, Output Shaft

- Item Dimensions: 15.3 x 6.8 x 6.8 inches

- Item Weight: 10.90 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2000 GMC C3500 Front Drive Axle Inner Shaft

Vehicle Fitment- 2000 GMC C3500 | Sierra SL, Sierra SLE, Sierra SLT | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

OEM (Genuine) 2000 GMC C3500 Axle Shafts

PartNumber: 12380993 Product Specifications

Product Specifications- Notes: All Models

- Other Names: Axle Shaft

- Fitment Type: Direct Replacement

- Part Description: 2000 GMC C3500 Axle Shafts

Vehicle Fitment- 2000 GMC C3500 | Sierra SL, Sierra SLE, Sierra SLT | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

OEM (Genuine) 2000 GMC C3500 Driveshaft

PartNumber: 15048496 Product Specifications

Product Specifications- Notes: 2WD W/15,000 Gvwr

- Part Description: 2000 GMC C3500 Driveshaft

Vehicle Fitment- 2000 GMC C3500 | Sierra SL, Sierra SLE, Sierra SLT | 8 Cyl 5.7 L CNG, 8 Cyl 5.7 L GAS, 8 Cyl 6.5 L DIESEL, 8 Cyl 7.4 L GAS

FAQ for Driveshaft Repair

Q: What is the recommended torque for installing the bolts when installing the propeller shaft?

A:

The recommended torque is 20 Nm (15 ft. lbs.).

By Bob

GM Specialist

29/10/2022Q: What is the recommended torque when installing the bolts and retainers to the yoke?

A:

The recommended torque is 20 Nm (26 ft. lbs.).

By Bob

GM Specialist

29/10/2022Q: What should be noticed in removing the propeller shaft-three pieces?

A:

You can not pound on the original propeller shaft yoke ears. The plastic injection joints may fracture. Never pry or place any tool between a yoke and a universal joint. You should tape the bearing cups onto the yoke to prevent the loss of bearing rollers.

By Bob

GM Specialist

29/10/2022Q: What is the recommended torque when installing the center-bearing support bolts?

A:

The recommended torque is 35 Nm (26 ft. lbs.).

By Bob

GM Specialist

29/10/2022Q: What should be noticed in the propeller shaft-one piece?

A:

When removing the propeller shaft, you can not attempt to remove the shaft by pounding on the yoke ears or using a tool between the yoke and the universal joint. If the propeller shaft is removed by using such means, the injection joints may fracture and lead to premature failure of the joint.

By Bob

GM Specialist

29/10/2022Q: What should be noted when installing the center-bearing support?

A:

You should align the center bearing support 90 degrees to the propeller shaft center lines.

By Bob

GM Specialist

29/10/2022Q: What should be noticed in removing the propeller shaft-two pieces?

A:

You should observe and accurately reference mark all driveline components relative to the propeller shaft and axles before disassembly. These components include the propeller shafts, drive axles, pinion flanges, output shafts, etc. All components must be reassembled in the exact relationship to each other as they were when removed.

By Bob

GM Specialist

29/10/2022See more FAQs (2)