< Back ×

2000 Chevrolet Venture Secondary Air Injection Check Valve

My Vehicle Change Vehicle

2000 Chevrolet Venture

< Back to View All

Emission Control

- Department

- Brands

- Prices

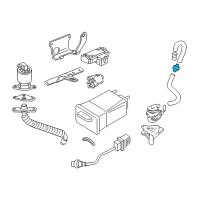

Dorman® OE Solutions Secondary Air Injection Check Valve for 2000 Chevrolet Venture

PartNumber: 911-004$105.52Product Specifications- Notes: Calif Emissions; Pkg Quantity: 1; Packaging Type: Box

- Finish: Chrome

- Inlet Size: 0.63"

- Material: Metal

- OE Part Number: 1231486, 24508523

- Outlet Size: 0.78"

- UPC: 019495213703

- Valve type: Wafer

- Working Temperature Range: -20 To 300

- Part Description: 2000 Chevrolet Venture OE Solutions Secondary Air Injection Check Valve

Vehicle Fitment- 2000 Chevrolet Venture | All Trims | 6 Cyl 3.4L

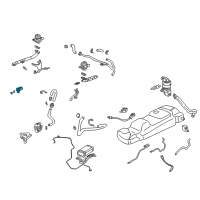

- $3.03 MSRP:

$4.14You Save: $1.11 (27%)Product Specifications- Notes: Air Pump, California Only

- Other Names: Diverter Valve, Duct, Valve

- Item Dimensions: 14.7 x 8.7 x 7.2 inches

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2000 Chevrolet Venture Duct Asm-Secondary Air Injection Pump

Vehicle Fitment- 2000 Chevrolet Venture | Base, LS, LT, Plus, Value, Warner Bros. | 6 Cyl 3.4 L GAS

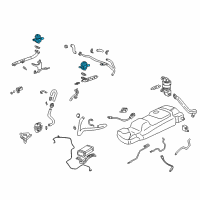

OEM (Genuine) 2000 Chevrolet Venture Valve Asm-Secondary Air Injection Vacuum Control Solenoid

PartNumber: 1997264Product Specifications- Notes: Air Pump, California Only

- Other Names: Diverter Valve, Solenoid, Solenoid Valve

- Item Dimensions: 4.6 x 2.8 x 2.9 inches

- Item Weight: 0.60 Pounds

- Fitment Type: Direct Replacement

- Part Description: 2000 Chevrolet Venture Valve Asm-Secondary Air Injection Vacuum Control Solenoid

Vehicle Fitment- 2000 Chevrolet Venture | Base, LS, LT, Plus, Value, Warner Bros. | 6 Cyl 3.4 L GAS

- Product Specifications

- Notes: Air Pump, California Only

- Location: Driver Side; Passenger Side

- Item Dimensions: 4.4 x 4.2 x 4.2 inches

- Item Weight: 0.80 Pounds

- Fitment Type: Direct Replacement

- Replaces: 24508415

- Part Description: 2000 Chevrolet Venture Valve, Secondary Air Injection Check

Vehicle Fitment- 2000 Chevrolet Venture | Base, LS, LT, Plus, Value, Warner Bros. | 6 Cyl 3.4 L GAS

FAQ for Secondary Air Injection Check Valve Repair

Q: What is the recommended torque for the locknut?

A:

The recommended torque is 10 N.m (89 lb in).

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the attaching screws?

A:

The recommended torque is 10 N.m (89 lb in).

By Bob

GM Specialist

01/11/2022Q: What is the recommended torque for the nut on the bracket stud?

A:

The recommended torque is 10 N.m (88 lb in).

By Bob

GM Specialist

01/11/2022Q: How to install the Air Injection Vacuum Bleed Valve?

A:

You should install the nut securing the vacuum bleed valve to the mounting stud. In addition, you should connect the electrical connector and the vacuum hoses.

By Bob

GM Specialist

01/11/2022Q: How to remove the Air Injection Vacuum Bleed Valve?

A:

You should disconnect the vacuum hoses and the electrical connector. In addition, you should remove the nut that attaches the vacuum bleed valve to the mounting stud and the vacuum bleed valve.

By Bob

GM Specialist

01/11/2022Q: What should you do before servicing the secondary air injection AIR system?

A:

You should allow the engine to cool to reduce the chance of severe burns.

By Bob

GM Specialist

01/11/2022Q: How to install the Air Check Valve/Pipe - Bank2?

A:

You should place the check valve/pipe assembly onto the bracket stud and manifold adaptors. In addition, you should connect the vacuum line and the clamp.

By Bob

GM Specialist

01/11/2022Q: How to remove the Air Check Valve/Pipe-Bank 1?

A:

First, you should loosen the air hose clamp. Next, you should disconnect the clamp, the air hose, the vacuum hose, and the air pipe. In addition, you should remove the check valve/pipe.

By Bob

GM Specialist

01/11/2022See more FAQs (3)